THORGEON Light ribbon-/hose/-strip

THORGEON Light ribbon-/hose/-strip as a lighting “material” you build with

THORGEON Light ribbon-/hose/-strip is best treated like an architectural material rather than a single product. You’re not only choosing brightness—you’re choosing how the light line behaves in corners, how it looks when people see it from the side, and how it survives heat, cleaning, and movement.

THORGEON Light ribbon-/hose/-strip: pick the format by what people will actually see

Instead of starting with voltage or watts, start with visibility:

- Hidden light (coves, behind lips, inside profiles): ribbon/LED tape is usually the cleanest and most precise.

- Visible light line (feature outlines, signage-like effects): neon-style diffused strip is usually safer for a continuous look.

- Rough handling or exposed runs (outdoor outlines, temporary installs): hose/rope formats are often more forgiving mechanically, but bulkier visually.

This approach prevents the common mismatch where the product “works electrically” but looks wrong in the space. Light ribbon, hose and strip solutions are commonly specified where flexible routing, continuous light lines and quick installation are required for accent and secondary lighting layers. In architectural detailing, retail displays and interior fit-outs that need clean, controllable linear illumination with tidy integration along edges and profiles, planners often start with adaptable options such as zext light ribbon hose strip, designed for precise outlining and consistent visual results. For residential interiors, hospitality spaces and decorative applications where ease of installation and balanced ambient output are key, designers frequently choose versatile ranges like trio light ribbon hose strip, supporting smooth light lines without complex mounting requirements. In environments that demand stable performance, reliable colour consistency and predictable behaviour across long switching cycles, specifiers often rely on established solutions such as sylvania light ribbon hose strip, ensuring repeatable results across different installation methods. Seasonal installations, façade accents and event-driven setups that require fast deployment and easy handling commonly incorporate decorative-ready lines like star trading light ribbon hose strip, enabling quick outlining and temporary illumination with minimal installation effort. And when projects require accessible, widely compatible LED strip and hose options for broad use cases — from display lighting to general ambient layers — planners often complete their selection with dependable ranges such as spectrum light ribbon hose strip.

THORGEON Light ribbon-/hose/-strip visual quality: how to avoid dots, hot spots, and glare

A premium-looking line comes from geometry, not marketing claims:

- Distance to diffuser: more depth between LEDs and the cover = smoother line.

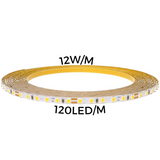

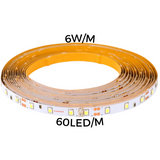

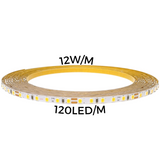

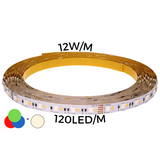

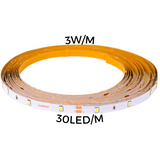

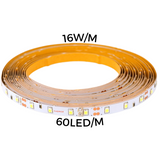

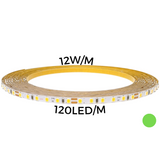

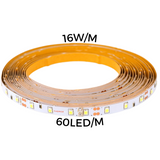

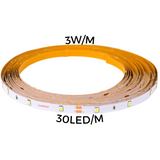

- LED spacing: tighter spacing reduces dotting, especially in shallow channels.

- Diffuser choice: opal softens and hides points; clear looks punchier but shows emitters.

- Viewing angles: if the line is in direct view, choose solutions that control brightness at high angles (diffusion or neon-style).

If the installation is at eye level (stairs, walls, furniture edges), glare control matters more than maximum output.

THORGEON Light ribbon-/hose/-strip power planning without surprises

Strips fail on projects when power planning is treated like an afterthought:

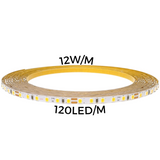

- 12 V vs 24 V: 24 V generally helps longer runs by reducing visible brightness drop.

- Voltage drop reality: the longer the run, the more likely you’ll see dim ends unless you feed smartly.

- Driver headroom: leave capacity so the driver runs cooler and lasts longer.

- Feed strategy: for longer lines, plan multiple feeds or end-to-end power injection rather than one long single feed.

A clean, even line is often more about correct feeding than “buying a brighter strip.”

THORGEON Light ribbon-/hose/-strip control options that match real use

Controls should be chosen by the way the space is operated:

- Simple dimming: for mood tuning in hospitality, bedrooms, reception areas.

- Scene control: when the same zone needs “day mode / evening mode / cleaning mode.”

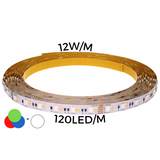

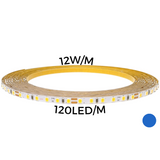

- Color (RGB/RGBW): only when color has a purpose (branding, events, wayfinding), not as a default.

- Camera-sensitive areas: prioritize stable dimming and flicker-conscious drivers in spaces where filming or displays are common.

A strong specification describes not just the control type, but also who controls it and how often it changes.

THORGEON Light ribbon-/hose/-strip environment fit: dry interiors vs damp vs exposed

Think in exposure levels, not room names:

- Dry, enclosed details: non-sealed ribbon in an aluminum profile is often best for cooling and service.

- Damp/condensation risk: sealed versions plus careful connector/end sealing.

- Outdoor exposure: prefer robust jackets (neon silicone or hose) and treat every cut end like a vulnerability that must be sealed properly.

Most “waterproof” failures happen at ends and joints, not through the middle of the strip.

THORGEON Light ribbon-/hose/-strip installation habits that extend lifetime

Small habits make the difference between “works for years” and “fails after months”:

- Use aluminum for heat: especially for higher-power ribbon strips.

- Don’t trust tape alone: combine tape with a profile or clips where heat or dust is expected.

- Respect bend radius: tight bends cause kinks and uneven output, especially in diffused silicone.

- Protect joints: strain relief at corners and connectors prevents intermittent faults.

- Test before closing: power up every segment before final sealing, and again after mounting.

In professional projects, documenting the cut points, feed points, and driver locations also makes future repairs much faster.

THORGEON Light ribbon-/hose/-strip where it performs especially well

- Ceiling coves and perimeter glow for “floating” ceilings

- Under-cabinet lighting where you want a clean work surface wash

- Shelving and displays where uniformity matters more than peak brightness

- Reception desks, bar fronts, and feature joinery lines

- Exterior outlines and pathways (with the correct protected format and sealing method)

THORGEON Light ribbon-/hose/-strip what to lock in during procurement

To keep delivery consistent and prevent missing parts:

- Format choice (ribbon vs hose vs neon-style) aligned to visibility and exposure

- Voltage, run lengths, and feed strategy

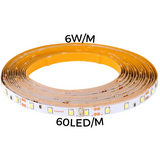

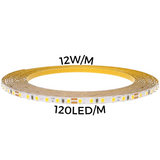

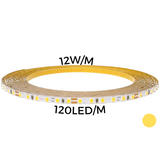

- Output per meter + driver sizing with headroom

- White tone or color strategy (and consistency across batches)

- Mounting method (profile depth, diffuser type, clips)

- Connector method (soldered vs plug) and sealing accessories

- A small spare set: one compatible driver/controller and a short matching section for quick fixes