Zext Light ribbon-/hose/-strip

Zext Light ribbon-/hose/-strip formats and how to pick the right one

Zext Light ribbon-/hose/-strip products usually fall into three practical formats, and each behaves differently in real installations:

- Ribbon / LED strip (tape): flexible PCB tape for profiles, coves, furniture, shelves, and hidden lines. Best when you need precision and neat integration.

- Hose / rope light: LEDs encapsulated in a round/oval jacket. More robust handling and longer decorative runs, but typically bulkier and less “architectural.”

- Neon-style strip (often called neon flex): a diffused silicone line with LEDs inside, designed to look continuous with minimal dotting—ideal when the light line is directly visible.

Choosing the format first prevents common failures like using bare ribbon strip where it will be exposed to moisture, impacts, or UV. Light ribbon, hose and strip solutions are widely used where flexible routing, continuous illumination and fast installation define the lighting requirement for accents and secondary layers. In residential interiors, hospitality areas and decorative architectural details that need clean linear light with tidy integration along profiles and edges, planners often begin with versatile options such as trio light ribbon hose strip, suited for creating controlled ambient lines without complex mounting. For cost-conscious upgrades and everyday decorative runs in small commercial and mixed-use spaces where simple installation and predictable output matter most, installers frequently choose practical ranges like thorgeon light ribbon hose strip, designed for straightforward outlining and general accent tasks. In environments that demand consistent performance, reliable colour stability and predictable behaviour over long switching cycles, specifiers often rely on established solutions such as sylvania light ribbon hose strip, supporting repeatable results across different applications and mounting methods. Seasonal installations, façade accents and event-driven setups that require easy handling and fast deployment commonly incorporate decorative-ready lines like star trading light ribbon hose strip, enabling quick outlining and temporary illumination with minimal installation effort. And when projects require accessible, widely compatible LED strip and hose options for broad use cases — from display lighting to general ambient layers — planners often complete their selection with dependable ranges such as spectrum light ribbon hose strip.

Zext Light ribbon-/hose/-strip assortment and the components that make it a system

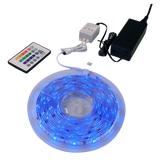

For reliable results, treat Zext Light ribbon-/hose/-strip as a system build, not just a roll of LEDs. A typical project needs:

- The strip/hose itself (rolls, cuttable lengths, or pre-made sections)

- Power supplies / drivers (plug-in, inline, or remote) matched to voltage and load

- Controllers (dimmers, remotes, wall controls, smart integration gateways)

- Mounting hardware (aluminum profiles, channels, clips, corner pieces)

- Diffusers and covers to manage glare and hide LED points

- Connectors and join kits (straight, corner, feeders, waterproof kits)

- End caps and sealing materials for protected versions

- Cable management (strain relief, glands, tidy terminations)

Most early failures are connector- and termination-related, so the accessory set matters as much as the LEDs.

Zext Light ribbon-/hose/-strip key specifications that change the final look

A few parameters determine whether the line looks premium or “dotty and uneven”:

- Voltage (12 V vs 24 V vs mains rope)

- 12 V: common for short decorative and furniture runs

- 24 V: better for longer runs with less brightness drop

- Mains rope/hose: long decorative outlines, usually thicker and less precise

- LED density: higher density generally looks smoother under shallow diffusers.

- Power per meter (W/m): drives brightness and heat—important for profile choice.

- CCT and consistency: keep one white tone across a room to avoid patchy coves.

- CRI: higher CRI is a practical upgrade for kitchens, wardrobes, retail, and hospitality finishes.

- Diffuser type: opal softens and hides points; clear looks brighter but shows LED dots.

If you want a “continuous glow,” prioritize density + diffuser depth rather than just buying a higher wattage strip.

Zext Light ribbon-/hose/-strip indoor vs outdoor planning: IP, UV, and sealing reality

“Waterproof” is not a single feature—it’s a whole installation method. For Zext Light ribbon-/hose/-strip, match protection to exposure:

- Dry indoor coves and profiles: non-sealed strips are easier to install and dissipate heat better in aluminum channels.

- Damp zones (bathrooms, near sinks, sheltered entrances): sealed strips with corrosion-resistant connectors and careful end sealing.

- Outdoor/exposed: neon-style silicone or fully jacketed hose formats are usually safer, with proper end caps, sealing, and secure fixing to prevent movement.

Cut ends and connectors are the #1 weak point—if they aren’t sealed correctly, even high-IP products can fail.

Zext Light ribbon-/hose/-strip drivers, dimming, and flicker-safe choices

Driver quality controls dimming smoothness, stability, and long-term reliability. For Zext Light ribbon-/hose/-strip:

- Use the correct constant-voltage driver for the strip voltage.

- Leave headroom (don’t run drivers at 100% load) to reduce stress and heat.

- Choose the right dimming method for the project:

- PWM dimming (common): fine for most spaces, but pay attention if cameras are used.

- 0–10 V / DALI / push-style control: useful when integrating into building controls or scene settings.

- Plan circuit grouping and inrush behavior when many drivers switch together.

If the space includes filming, displays, or frequent video calls, stable low-flicker behavior becomes a real spec requirement, not a luxury.

Zext Light ribbon-/hose/-strip installation rules that prevent common failures

A clean installation is mostly discipline:

- Heat management: higher-output ribbon strips should be mounted in aluminum profiles for cooling.

- Adhesive reality: clean/degrease surfaces; avoid relying on tape alone in warm or dusty areas—use profiles/clips.

- Feed longer runs correctly: voltage drop causes visible dimming; use shorter runs, heavier cable, or feed from both ends where appropriate.

- Respect bend radius: especially for neon-style silicone—tight bends cause kinks and uneven light.

- Cut only at marked points: incorrect cuts can kill segments or create overheating.

- Strain relief: protect wire joints and corners so movement doesn’t tear pads or connectors.

Best practice: test each section before final sealing and again after mounting, while it’s still accessible.

Zext Light ribbon-/hose/-strip design tips to avoid dotting and glare

If the goal is architectural “light, not LEDs,” these choices help:

- Use deeper profiles (more distance to diffuser) for smoother lines.

- Choose neon-style diffusion where the line is directly visible.

- Hide the source behind lips/coves so people see the glow, not the emitter.

- Offset strips in shelves/cabinets to avoid harsh reflections on glossy surfaces.

Often, improving the profile and diffuser gives a better result than upgrading the strip wattage.

Zext Light ribbon-/hose/-strip common use cases that deliver strong results

- Cove lighting and perimeter glow

- Under-cabinet task lighting (with glare control)

- Shelving and display cases (high CRI recommended)

- Stair and handrail accents (with protected housing and secure fixing)

- Reception desks and feature walls

- Outdoor outlines and wayfinding lines (hose/neon formats with proper sealing)

Zext Light ribbon-/hose/-strip procurement checklist for consistent deliveries

Before ordering Zext Light ribbon-/hose/-strip, lock down:

- Format: ribbon vs hose vs neon-style

- Voltage and total run lengths (including corners/returns)

- W/m and driver sizing with headroom

- CCT / RGB / RGBW and control method

- IP level matched to exposure (and sealing method for cuts/joins)

- Connector plan: soldered vs plug connectors, waterproof join kits if needed

- Profiles/clips/diffusers/end caps and cable management parts

- Spare plan: keeping one spare driver/controller is often the fastest fix in the future

Zext Light ribbon-/hose/-strip mistakes to avoid

- High-power strip without an aluminum profile (overheats and ages faster)

- Long runs fed from one end only (visible brightness drop)

- Skipping sealing on ends/connectors in damp/outdoor areas

- Mixing similar whites in one space (patchy look)

- Relying on tape-only mounting in warm areas (peels over time)