WAGO Electrical Installation

Mounting carrier

Busbar carrier

Mounting carrier

Mounting carrier

Install teams pick WAGO when they want terminations that stay tight without re-torque, fast test access, and clear limits for conductor size, strip length, and IP. Below is a practical, assortment-first overview you can drop straight into specifications and method statements.

wago installation materials scope and configuration choices

The range covers junction and pull boxes (≈80–240 mm), compact DIN housings for local I/O, and plate kits that keep Ø68 mm cutouts and 60 mm screw lines consistent across rooms. Gland plates accept 16/20/25 mm entries (membrane or threaded), divider inserts maintain SELV/mains segregation, and label windows keep circuit IDs visible after fit-off. Stock wago installation materials by wall type, box depth, entry style, and CPR/LSZH requirement so first-fix details don’t drift between floors.

wago installation accessories seals, strain relief, and identification

Ingress and pull tests usually fail at the cable entry, not the terminal. Kits include IP gaskets, stepped compression glands matched to jacket Ø, strain-relief saddles that move mechanical load off terminations, and marker strips sized for trunking channels. Use color separators where SELV shares a box with mains, and keep screw packs matched to body material (PC/ABS vs metal). Crews catalog wago installation accessories by IP class, thread set, and label width to avoid site-time improvisation.

wago electrical installation spring clamp practice and compliance map

Push-in springs keep contact force stable over time, reduce resistance growth, and expose isolate-and-test positions for metering. Inline connectors follow IEC/EN 60998; rail terminals follow IEC/EN 60947-7-1/-7-2; ingress claims reference IEC 60529. Typical strip lengths are printed 8–11 mm; conductor classes (solid, stranded, fine-strand with/without ferrule) are explicitly stated to prevent borderline insertions. Using wago electrical installation components standardizes inspection steps for insulation, polarity, and loop tests.

wago mounting systems rails, plates, and layout discipline

Perforated or solid DIN rails with end-stops, earth/neutral bars, and pre-drilled backplates keep small assemblies repeatable. Zinc-plated steel suits most interiors; stainless variants serve cleaned or coastal areas. Publish a single rail length and hole pattern template for all risers, keep end-stop positions constant, and reserve marker zones for device IDs. Panel shops align to wago mounting systems so terminal blocks, relays, and interface modules land on the same centers every time.

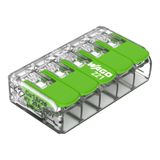

wago wiring connectors families and correct sizing

Working sets typically include lever-type 221 (0.2–4 mm², re-usable), compact push-in 2273 for solid 0.5–2.5 mm², lighting connectors 224 (solid in from feed, flexible out to luminaire), and micro 2070 for tight canopies. Clear inspection windows verify insertion; parked levers isolate conductors for testing. Choose wago wiring connectors by conductor class, cross-section, reusability requirement, and available box space to pass pull and temperature-rise checks first time.

wago terminal installation TOPJOB® S blocks, jumpers, and diagnostics

Rail blocks in 2.5/4 mm² sizes (≈24–32 A typical) provide push-in CAGE CLAMP®, functional earth versions, multi-tier options, pluggable jumpers, and integrated test points. Marking can be continuous strip or per-terminal tag, and PE bars align with common rail offsets. Standardizing on one family for wago terminal installation keeps accessories (end plates, jumpers, markers) interchangeable across all small boards.

wago installation hardware prebuilt rails and ceiling field kits

Pre-assembled rail segments arrive with blocks, jumpers, end-stops, N/PE links, and printed tag IDs; ceiling kits bundle the correct box, glands, strain-relief, labels, and connector family against drawing call-outs. Procure wago installation hardware by conductor window, IP set, and label format to reduce FAT time and avoid rework during witness tests.

Technical specifications and standards that matter

Conductor windows commonly 0.2…4 mm² (lever types) and 0.5…2.5 mm² (compact solid); rail blocks 2.5/4 mm² around 24–32 A (verify heat groups). Strip 8–11 mm as printed on the body. Compliance anchors: IEC/EN 60998 (inline connectors), IEC/EN 60947-7-1/-7-2 (rail terminals), IEC 60529 (IP for boxed assemblies). Maintain SELV/mains segregation with dividers; apply 360° braid clamps on gland plates near VFDs to control common-mode noise.

Applications and compatibility

• Offices/hospitality: compact push-ins above ceilings, DIN micro-housings with labeled rails for local control.

• Education/healthcare: LSZH boxes, lever types for quick isolation during maintenance.

• Logistics/plant: stainless rails in wash zones; larger cross-section rail blocks for longer runs.

The ecosystem pairs cleanly with common luminaires, sensors, and distribution gear—no special tooling required.

Selection criteria for B2B buyers

- Fix conductor class and cross-section → lever vs push-in, strip length, and available box volume.

- Lock enclosure/IP and any LSZH/CPR need; size glands to jacket Ø and publish clamp ranges.

- Define rail block family, jumper plan, marker format, and end-stop type for repeatable panels.

- Document EMC and segregation rules when analog/bus lines share space with mains.

- Barcode spares to drawing tags so swap-outs preserve labeling and test sequence.

Advantages of working with Bankoflamps

Get individual B2B pricing with custom offers and a dedicated account manager. Quotes arrive fast—around an hour—and orders place quickly by EAN/MPN. You have real-time stock visibility across EU warehouses, downloadable price lists that stay current, and clear lead-time and order-status tracking. Purchase history and analytics are available in the portal. Trusted clients can use post-payment terms up to 30 days. We manage consolidated shipments to reduce delivery costs, keep pricing stable with validity dates, and serve clients in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.