WAGO Electric box (breaker panel)

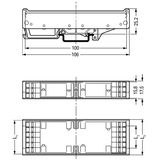

Busbar carrier

Wire Clamps Set

Steel carrier rail

Copper carrier rail

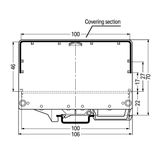

Empty housing

Empty housing

Empty housing

Empty housing

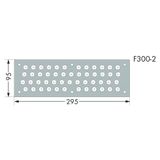

Flange plate

Housing 55 mm gray

Project teams want boards that install cleanly, label well, and survive maintenance without mystery fasteners or vague ratings. The WAGO platform focuses on predictable geometry, clear terminal windows, and accessories that keep segregation and EMC under control—so acceptance testing doesn’t stall at midnight.

wago distribution boards architecture, geometry, and layout logic

A modern small-power board lives or dies on its mechanical discipline. With wago distribution boards you keep a consistent backplate grid, pre-punched gland-plate patterns for M16/M20/M25, and rail spacing that leaves hand clearance for ferrules and test probes. Door cut-outs align with device handle throws, and marker rails run the full width for unbroken labeling. Neutral and earth bars land on the same pitch across sizes, which means your wiring diagrams don’t change when a row count changes. Define cable entry zones (top/bottom), reserve a bay for surge and metering, and document torque values on the inside label—field crews will follow what’s printed.

wago electrical enclosures environmental classes, doors, and service access

Plant rooms, corridors, guest floors, and rooftops all ask different things of the shell. The wago electrical enclosures range covers IP ratings appropriate to location, powder-coated steel for interiors, and stainless options for harsh or cleaned spaces; hinges and locks are specified so doors hold alignment over time. Removable gland plates stop the common “drill in place” shortcut that sheds swarf into live rails. Depth is sized for bend radius on larger conductors and to keep SELV and mains on distinct planes. Clearances around RCBO handles and indicators are maintained so inspection photos are readable without removing covers—small details that save time at sign-off.

wago power distribution panels device coordination, rails, and heat paths

Space is always tight, so rail layout and device selection must be coordinated early. In wago power distribution panels, the rail sequence (SPD → main switch → metering → RCBO rows) keeps service loops tidy and measurement points accessible. End-stops and wire-duct covers are part of the BOM—no improvisation on site. Heat grouping is credible: drivers and transformers don’t sit under dense RCBOs, and blanking pieces cut stray convection. Leave room for future ways and put the marker scheme in the drawings; the next technician will thank you.

wago junction boxes pull points, segregation, and labeling that survives

Every riser depends on the small boxes being right. Use wago junction boxes sized for the actual pull—80–240 mm variants with corner fixings, divider plates for SELV/mains separation, and compression glands matched to jacket Ø. Internal marker pads take QR or printed IDs; lids accept date/test decals. Membrane entries are fine for light duty; threaded entries belong anywhere ingress matters. Keep 8–11 mm strip windows and ferrule policy on the lid so night crews don’t have to guess.

wago modular distribution systems expansion without rewiring

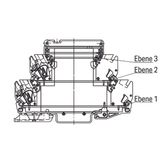

When the brief changes late, a stacked approach saves hours. With wago modular distribution systems, you add rail sections, jumpers, and bus links on a defined pitch; spare DIN space and blank fronts are planned from day one. Pre-wired harnesses route neutral/earth cleanly, and your marker plan extends without renumbering. That’s how expansions stay neat instead of turning into a splice farm.

wago electrical cabinets form factors for rooms, risers, and rooftops

Not every location wants the same footprint. The wago electrical cabinets assortment covers wall-mount for rooms, shallow riser versions where corridors are tight, and deeper shells where transformers or control gear sit inside. Doors can swing left or right; viewing windows are sized so breaker flags and meter displays are visible at a glance. Choose handle types that work with your lock policy and publish the hinge side on drawings to prevent clashes with nearby mullions.

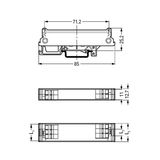

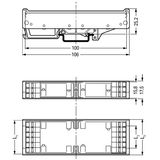

wago installation boards preassembled rails and documented torque

Factory-built rail sets reduce FAT time and make site QA faster. Order wago installation boards with terminals, jumpers, end-stops, N/PE bars, and printed tag IDs fitted to your layout. Include a front sheet that states conductor ranges, strip lengths, and torque for each device class—then repeat those notes on the inside of the door. Consistency is what turns night work into routine work.

Technical touchpoints to fix in the spec

- Rails: assign device order, end-stops, and spare pitch; keep probe access in front of test points.

- Entries: M-thread sizes and clamp ranges documented; IP claims rely on using the right gland set.

- Wiring: conductor classes and ferrule policy stated; strip 8–11 mm typical; publish torque bands.

- Segregation & EMC: SELV/mains dividers; 360° shield bonds at gland plates near drives.

- Labeling: uninterrupted marker rails; device IDs mirrored in PDFs and on the door chart.

Selection checklist for B2B buyers

- Fix environment (IP/IK, material, door swing) and reserve zones for SPD/metering.

- Define rail plan and spare capacity; lock marker format and numbering.

- Choose entry strategy (top/bottom, thread sizes) and the gland kit for each cable OD.

- Publish wiring rules: conductor windows, strip length, ferrules, and torque.

- Where expansion is likely, specify modular sections and harness jumpers from the start.

Advantages of working with Bankoflamps

Bankoflamps supports trade customers with individual B2B pricing, custom offers, and a dedicated account manager. Quotes are typically returned in about an hour, and ordering by EAN/MPN is straightforward. Through the portal you can view EU-wide stock in real time, track lead times and order status, and download up-to-date price lists; purchase history and analytics are also available. Trusted clients may use post-payment terms up to 30 days. Shipments are consolidated to lower delivery costs, prices carry defined validity dates, and we serve customers in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.