Register to unlock your exclusive B2B prices and start shopping. Sign up now!

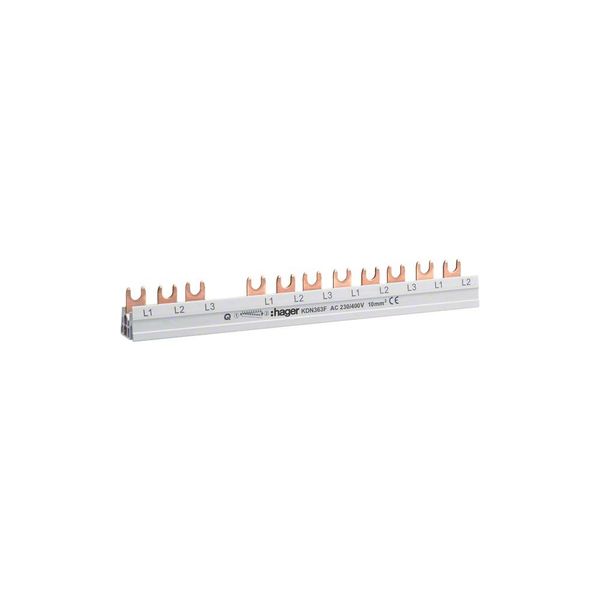

Insulated busbar 3 Pole with Fork Connection 10mm² 63A 12 Modules

In stock

Price (excl. VAT):

10,11 €

per pcs

EAN: 3250613741068

MPN: KDN363F

Package: 1

Box: 50

Pallet: 4500

Estimate delivery time at our warehouse (approx.):

2-4 weeks

Technical Information

| Item condition | New |

| Manufacture name | Insulated busbar 3 Pole with Fork Connection 10mm² 63A 12 Modules |

| Brand | Hager |

| Categories |

Busbar Systems and Accessories

|

| Country of origin* | CN |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8536 9001 00 |

| Insulated | Yes |

| Rated permanent current Iu | 63 A |

| Number of poles | 3 |

Packing details

| Packing level 1 | 3250613741068 |

| Packing level 2 | 3250613741068 |

| Packing level 3 | 3250613741068 |

Other Technical data

| Colour | Grey |

| Number of phases | 3 |

| Cross section | 10 mm² |

| Length | 210 mm |

| Width in number of modular spacings | 12 |

| Rated surge voltage | 4.5 kV |

| Type of electric connection | Fork |

| Suitable for devices with auxiliary switch | No |

| Suitable for devices with N-conductor | No |

| Suitable for number of devices | 4 |

| Max. rated operation voltage Ue | 400 V |

| Module width | 17.8 mm |

Description

This component functions as a pressure regulator within fluid control systems. It maintains consistent downstream pressure regardless of variations in the input flow or pressure fluctuations, ensuring stability and optimal performance for connected equipment.

**Materials & Construction:**

Main housing fabricated from corrosion-resistant alloy. Internal components include precision-machined valves, seals rated for high-pressure tolerances, pre-calibrated spring mechanisms. Standard industrial threading on all ports–compatible with most pipe fittings used in hydraulic systems.

**Performance Specifications:**

Pressure adjustment range: 0-10 bar (0-150 PSI). Maximum inlet pressure threshold: 12 bar (175 PSI). Operating temperature limits: -20°C to 80°C (-4°F to 176°F). Allows up to ±1% deviation in regulated output under load conditions. Compatible with non-aggressive fluids only; unsuitable for gases or mixed materials.

**Dimensions & Installation Requirements:**

Physical dimensions: Height - 85mm; Width - 45mm; Depth - 40mm. Port diameters standard at G1/4" threaded connections. Requires mounting bracket or secure inline positioning to prevent vibration damage during operation.

- Not suited for applications involving caustic chemicals or refrigerants due to seal material limitations.

- Periodic maintenance needed — recommended replacement interval after 5 years under continuous use.

- Accuracy can degrade over time if exposed to significant particulate contaminants.

- Cannot regulate below a minimum output threshold of roughly ~0.5 bar reliably.

Alternative EAN

3,23 €

per pcs

Subtotal: 32,30 €

MOQ: 10

EAN: 4001869318400

MPN: 5ST3624

Package: 1

Box: 10

Suitable for

Berker

SPD 1P pluggable 40kA ind.

56,15 €

EAN: 3250615660701

MPN: SPN115

Package: 1

Pallet: 2592

157,85 €

EAN: 3250615660718

MPN: SPN117

Package: 1

Pallet: 2592

Berker

SPD 1P pluggable 40kA

145,84 €

EAN: 3250615660725

MPN: SPN118

Package: 1

Pallet: 2592

Berker

SPD 3P pluggable 40kA ind.

208,09 €

EAN: 3250615660732

MPN: SPN315

Package: 1

Pallet: 1152

394,93 €

EAN: 3250615660749

MPN: SPN317

Package: 1

Pallet: 1152

1 581,20 €

EAN: 3250615660923

MPN: SPN801

Package: 1

Pallet: 192

1 301,20 €

EAN: 3250615660930

MPN: SPN801R

Package: 1

Pallet: 192

1 435,46 €

EAN: 3250615660947

MPN: SPN802

Package: 1

Pallet: 192

1 704,38 €

EAN: 3250615660954

MPN: SPN802R

Package: 1

Pallet: 192

Hager

SPD 1P monobloc 50kA

131,17 €

EAN: 3250615661203

MPN: SP120

Package: 1

Pallet: 1440

Suitable for

3250615660756

3250615660763