WAGO Luminaire accessories

Install teams care about three things around each fixture: terminations that pass pull and insulation tests every time, ingress that survives maintenance, and geometry that doesn’t fight the ceiling. The lineup below is organized the way site crews stock it—by conductor windows, clamp ranges, seal sets, and sleeve types—so swaps don’t move photometry or IP.

wago luminaire accessories scope, geometry, and acceptance-test logic

On real ceilings, everything between the gear tray and the visible trim decides whether inspection is easy or painful. With wago luminaire accessories, you map each fixture family to a simple matrix: conductor class and cross-section for tails (e.g., 0.5…2.5 mm² fine-strand with ferrules), strip lengths printed on parts (8–11 mm typical), clamp ranges that match the jacket Ø at the gland, and probe points visible after fit-off. Crews also lock the cutout (Ø68 mm where plates are shared), screw line (60 mm), and multi-gang pitch in the same document, so polarity, loop/Zs, and IR tests are done without removing trims. Stocking by matrix means you don’t negotiate torque on a ladder at midnight—you repeat the same tightening and test routine on every room.

wago lighting accessories IP, EMC, and loop-through rules for rows and clusters

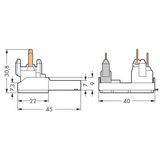

Rows and clusters only behave when loop-through is planned from day one. The wago lighting accessories bundle for lines usually includes 2–5-pole blocks with separate bays for L/N/PE and control, bridge links sized for current, and cord grips that anchor the jacket—not the copper. In damp points, gasket rings and compression glands must be matched to thread and jacket; IP claims depend on that fit more than anything else. EMC is handled at the entry: 360° braid clamps at gland plates where drives sit nearby, single-end bonds for analogue lines, and explicit separation from mains inside the canopy. Publishing these three items—loop-through scheme, ingress kit, and shield strategy—turns acceptance into a checklist instead of a troubleshooting session.

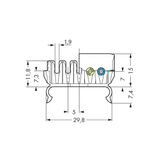

wago mounting systems brackets, spacer logic, and sleeves that survive service

Ceiling substrates vary floor to floor; the mechanical kit can’t. With wago mounting systems, you standardize three mechanical families. 1) Adapter plates that keep focal height and bezel gaps correct even when you inherit oversized or off-centre holes; 2) Spacer rings (2–10 mm) for proud plaster and tile planes so trims sit level; 3) Recessed sleeves for exterior or floor-adjacent zones with gravel beds and drains below the can—standing water kills seals faster than anything else. Screw length matters: self-tappers for PC/ABS, machine screws for metal trims, with torque values printed to stop crushed gaskets. When those basics are fixed, optics aim correctly and IP survives after the first maintenance round.

wago connectors and adapters quick-coupling, polarity cues, and service isolation

Fast finishing depends on keyed interfaces that don’t let crews cross power and control. Use wago connectors and adapters with clear insertion windows and parked-lever “isolate for test” positions so you can meter without breaking the joint. IP20 couplers handle dry voids; sealed pairs protect canopies and façades. Color cues on control cores (1–10 V/DALI) and embossed polarity marks reduce night-shift mix-ups. For long runs, publish max secondary lengths and voltage-drop limits with the connector spec; when rows share one way on the board, list inrush data so RCBOs don’t nuisance-trip at switch-on.

wago installation accessories seals, glands, and SELV barriers that keep ratings honest

Ingress and segregation fail at the entry point, not the terminal. The field kit under wago installation accessories pairs IP44 gasket rings, compression glands sized to jacket Ø and thread, and color-coded barriers that maintain clearances when control and mains share a canopy. Add repair collars for chipped cutouts and screw packs that match substrate, and you preserve both the trim line and the rating after a swap.

wago wiring components through-blocks, bridges, and test access in tight canopies

Above the tray, the tidy solution is separate bays for L/N/PE and for dimming cores, with bridge links that let rows daisy-chain without junction boxes. Choose wago wiring components with ferrule-friendly cages and visible probe points, so insulation, polarity, and loop/Zs can be verified with the plate on. That single detail removes half the friction at handover.

wago spare parts for luminaires drivers, optics, and seal kits tied to the exact EAN

Service stock should restore the original performance, not alter it. Keep wago spare parts for luminaires mapped to each fixture EAN: driver trays with stated tc, emergency modules, opal/prismatic diffusers or reflector/lens sets, and the correct seal kit with matching screws. That way beam shape, UGR, and IP come back exactly as commissioned.

Advantages of working with Bankoflamps

Get individual B2B pricing with custom offers and a dedicated account manager. Quotes arrive fast—around an hour—and orders place quickly by EAN/MPN. You have real-time stock visibility across EU warehouses, downloadable price lists that stay current, and clear lead-time and order-status tracking. Purchase history and analytics are available in the portal. Trusted clients can use post-payment terms up to 30 days. We manage consolidated shipments to reduce delivery costs, keep pricing stable with validity dates, and serve clients in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.