TE Connectivity

Connector:wire-wire;Superseal 1.5;plug;female;PIN:4;IP67

Strain relief;Application:4PIN plugs;Superseal 1.5

Connector:wire-wire;Superseal 1.5;plug;male;PIN:5;IP67;24VDC

Strain relief;Application:3PIN plugs;Superseal 1.5

Connector:wire-wire;Superseal 1.5;plug;male;PIN:4;IP67;24VDC

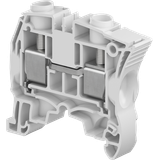

End Cover, For Use With SNK Terminal Blocks, Grey

PLC konektor RI1621N/P-F-24VDC, 1SNA020833R1600

Rail terminal ZS16 /1SNK510010R0000

RC55 (801 A 900) HORIZ,

RC55 (100 X E) VERT,

RC55 (100 X D) VERT,

RC55 (100 X F) VERT,

RC55 (100 X J) VERT,

RC65 (100 X =) HORIZ,

RC65 (100 X Y) HORIZ,

RC65 (100 X R) VERT,

RC65 (100 X 10) VERT,

RC65 (100 X 7) VERT,

RC65 (100 X 12) VERT,

RC610 (901 A 1000) VERT,

RC610 (100 X Q) VERT,

RC610 (100 X M) VERT,

RC810 (100 X J) HORIZ,

RC810 (100 X O) HORIZ,

RC810 (100 X J) VERT,

RC810 (100 X K) VERT,

RC810 (100 X M) VERT,

RC810 (100 X Q) VERT,

RC1010 10X(81 A 88) HORIZ,

RCAL85 10X(31X40) HORIZ,

RC1010 10X(137 A 144) HORIZ

RCAL85 10X(51X60) HORIZ,

RCAL85 10X(81A90) HORIZ,

RCAL85 10X(101A110) HORIZ,

RC1010 10X(169 A 176) HORIZ

RC1010 10X(185 A 192) HORIZ

SUPPORT PLATE FOR BA4 WIRE MAKERS DEDICATED TO FEEDER USAGE PURCHASED SEPARATELY, HTP500-BA4

RCAL85 10X(131A140) HORIZ,

MARKETING SYSTEM CABLE, HTP500-WB

RCAL85 10X(161A170) HORIZ,

RC1010 1X(241 A 320) HORIZ

MARKETING SYSTEMS, 1 RIBBON CASSETTE, RED, RIB-RS

RC1010 1X(481 A 560) HORIZ

RCAL85 10X(0A9) VERT,

RC1010 1X(721 A 800) HORIZ

RCAL85 10X(1A10) VERT,

RCAL85 10X(31A40) VERT,

DEVICE MARKER, 1 PIECE, 330G SPRC 15

M6/13,FF,4, RAILWAY TERMINAL BLOCK, FEED THROUGH, BEIGE, TWO STUD WIRE LUG CONNECTION

D4/8,SFDT2,I,ADO2

D4/8,SFLT2,I,ADO2

M6/12,FF, SPECIFIC TERMINAL BLOCK, FEED THROUGH, GREY, 0.492 SPACING, 12X51.5X33MM, 41A

(INT)BOM16S, CONNECTING INTERFACE, SINGLE WIRE, 2X20 POLES, SCREW CLAMP, 112X58.5X44MM

MODULAR TERMINAL BLOCKS, FEED-THROUGH, SCREW CLAMP TERMINAL BLOCK, GRAY, PRODUCT SPACING .205 IN [5.2 MM], 6 POSITION, DIN RAIL

MODULAR TERMINAL BLOCKS, FEED-THROUGH, SCREW CLAMP TERMINAL BLOCK, GRAY, PRODUCT SPACING .315 IN [8 MM], 2 POSITION, DIN RAIL

END SECTION - DARK GREY

ZS10-OR ORANGE TERMINAL BLOCK

TE Connectivity installation and mechanical base for panels

For panel builders and contractors, the TE Connectivity range lets you start from the mechanical base and build up to a complete electrical system. Core installation hardware is grouped under TE Connectivity installation, covering components you use on almost every board or cabinet: mounting profiles, small hardware, accessories for routing and securing conductors.

To keep assemblies robust under vibration and thermal cycling, many OEMs standardise on TE Connectivity fixings for clamps, clips and fasteners. In parallel, TE Connectivity mounting materials help you maintain clear cable routing, strain relief and separation between power, control and communication circuits – points that are always present in audit and FAT checklists.

On site, installation speed and repeatability depend on the right tools. For this reason, many teams align their tool sets with TE Connectivity hand tools, so crimping, cutting and stripping are all done with devices matched to the terminals and connectors in use. This reduces termination errors and improves long term reliability of every connection in the panel.

TE Connectivity control, protection and distribution

Once the mechanical setup is defined, you specify how loads are switched and protected. The backbone of this layer is TE Connectivity automatics and control, where you configure contactors, starters and auxiliary control devices that drive motors, heaters and process loads. Signal conditioning, interlocking and galvanic isolation are handled by TE Connectivity relays, which sit between sensors, PLC inputs and higher power stages.

Feeder and final circuit protection is concentrated in TE Connectivity breakers and DIN modular devices. Here you choose breakers, RCDs and modular accessories according to short circuit levels, selectivity and coordination with upstream devices. In applications that still require very fast disconnection or gG/gR characteristics, TE Connectivity fuses complete selectivity plans and protect sensitive equipment.

For projects where time on site is critical, it can be more efficient to use factory built assemblies. In that case, TE Connectivity preassembled distribution units allow you to bring in ready wired boards with defined ratings and layouts, reducing installation hours and simplifying documentation for the end user.

TE Connectivity data, telecommunication and industrial connections

Modern control systems depend just as much on signal integrity as on power distribution. The portfolio of TE Connectivity data and telecommunication covers copper cabling and components for Ethernet, fieldbus and control networks inside cabinets and across plant areas. When you need robust connections in harsh environments, TE Connectivity industrial connections and blocks provide terminal blocks and connectors with appropriate creepage distances, clamping forces and temperature ratings.

In many projects there are also niche or legacy requirements that do not fit a standard category. These can be handled via TE Connectivity noncategorized products, which typically include special adaptors, older form factors or project specific parts. Procurement teams often treat these as controlled exceptions in their internal standards to keep future maintenance manageable.

Switching devices, sockets and field distribution with TE Connectivity

At the interface between fixed wiring and users or equipment, the focus shifts to ergonomics, mechanical robustness and IP protection. The family of TE Connectivity switches and sockets allows you to specify consistent design lines for industrial and commercial environments, with options for different ingress protection levels and mounting methods. Where the project requires dedicated outlet types, TE Connectivity sockets provide variants for specific current ratings, pin configurations and applications.

Accessories are often decisive at inspection. With TE Connectivity accessories switches and sockets you can complete installations using frames, covers and small parts designed for the same devices, instead of mixing third party components. This is important for maintaining IP ratings, mechanical integrity and a uniform visual appearance throughout the facility.

Tools, measuring instruments and QA with TE Connectivity

Commissioning and maintenance depend on repeatable measurements and safe work procedures. The combined range of TE Connectivity tools measuring instruments and protection is intended to support these tasks with appropriate test devices, tools and basic PPE matched to the voltage levels present in your panels. For detailed verification and troubleshooting, TE Connectivity measuring instruments cover multimeters, testers and other diagnostic equipment used by electricians and service technicians.

A typical QA checklist for a TE Connectivity based system will include verification that specified components are used consistently (from breakers to terminals), that torque and crimping values are respected via the recommended TE Connectivity hand tools, and that key measurements at start up are performed with calibrated instruments from the same ecosystem.

With this structured approach – mechanical base, control and protection, communication, interfaces, and tools – TE Connectivity components from TE Connectivity installation up to TE Connectivity preassembled distribution units can be combined into a coherent standard for your projects, making engineering, purchasing and long term operation more predictable and easier to scale across multiple sites.

![MODULAR TERMINAL BLOCKS, FEED-THROUGH, SCREW CLAMP TERMINAL BLOCK, GRAY, PRODUCT SPACING .205 IN [5.2 MM], 6 POSITION, DIN RAIL](https://image-cdn.bankoflamps.com/160x160/f7/f756baff05f7ac500de99d5fe800134a6975d3c7.jpg)

![MODULAR TERMINAL BLOCKS, FEED-THROUGH, SCREW CLAMP TERMINAL BLOCK, GRAY, PRODUCT SPACING .315 IN [8 MM], 2 POSITION, DIN RAIL](https://image-cdn.bankoflamps.com/160x160/51/517c0695d985d4d93675cc69af09a129c1299888.jpg)