Register to unlock your exclusive B2B prices and start shopping. Sign up now!

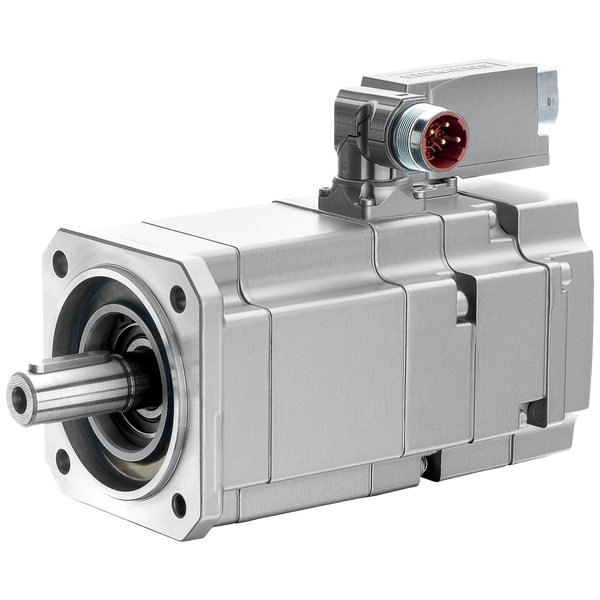

SIMOTICS S Synchronous servo motor 1FK7 Compact, DC link 300V 0.85Nm, 100K, 6000rpm 0.38kW, Naturally

Order only

Price (excl. VAT):

1 422,26 €

per pcs

EAN: 0662643207262

MPN: 1FK7022-5AK21-1DA3

Package: 1

Estimate delivery time at our warehouse (approx.):

4-6 weeks

Technical Information

| Item condition | New |

| Manufacture name | SIMOTICS S Synchronous servo motor 1FK7 Compact, DC link 300V 0.85Nm, 100K, 6000rpm 0.38kW, Naturally |

| Brand | Siemens |

| Categories |

Standard Electric Motors

|

| Country of origin* | RO |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8501 5100 00 |

| Rated current | 0 A |

| Rated voltage | 0 V |

| Rated performance at rated frequency | 0 kW |

Packing details

| Packing level 1 | 0662643207262 |

Other Technical data

| Number of phases | 0 |

| Number of poles | 0 |

| Rated rotational speed at rated frequency | 0 1/min |

| Frame size according to IEC | 0 mm |

| Full-load efficiency | 0 % |

| Starting current ratio | 0 |

| Starting torque ratio | 0 |

| Breakdown torque ratio | 0 |

| Voltage anti-condensation heater | 0 V |

| Output power anti-condensation heater | 0 W |

| With positive temperature coefficient resistor (PTC) | No |

| With resistance temperature detector (RTD) | No |

| Overload capability | No |

| Suitable for frequency control | No |

| With anti-condensation | No |

| Nominal torque | 0 Nm |

| Power factor | 0 |

Description

## Product Overview

### SIMOTICS S Synchronous Servo Motor 1FK7

- **Torque and Speed Parameters**

The motor delivers a nominal torque of 0.85 Nm with a maximum rotational speed of 6000 rpm, facilitating high-precision torque control in dynamic servo applications. Power output is rated at 0.38 kW, optimized for compact drive solutions within constrained form factors.

- **Electrical Configuration and DC Link**

Equipped with a 300V DC link voltage architecture, the motor supports stable power conversion with minimal ripple, ensuring consistent electromagnetic performance and thermal management during rapid load changes.

### Electrical Protection Components

- **Fuse NH3 630A**

High-capacity NH3-type fuse rated at 630A, designed for rapid interruption of fault currents to protect the electrical circuitry against overload and short-circuit conditions.

- **DELTA Switches and Pushbutton LED Inserts**

Robust DELTA switching elements incorporate LED lamp inserts for enhanced control function visibility, providing reliable mechanical endurance and electrical switching characteristics compatible with industrial control panels.

### DELTA Aluminum-Metallic Frame Variants

- **Modular Frame Sizes**

Available in multiple configurations including 5-fold (364x80 mm), 4-fold (293x80 mm), 2-fold (151x80 mm), and 1-fold (80x80 mm) aluminum-metallic frames, these structures provide scalable mounting options with high rigidity and electromagnetic shielding.

- **i-System Components**

Supplementary aluminum-metallic components include the Antenna cover plate (55x55 mm) for broadband compatibility and Rocker switches engineered for universal on/off control functionality, integrating seamlessly within the DELTA control interface ecosystem.

### Technical Notes

- No quantified data available for poles, rated voltage/current, power factor, or frequency-related parameters.

- Absence of anti-condensation features such as heaters or PTC/RTD sensors limits operation in high-humidity or harsh environmental conditions.

- Not designed for frequency control or overload conditions, restricting suitability to specific servo motor drive scenarios without variable frequency modulation or high transient load demands.

This technical synthesis reflects the core specifications and component attributes essential for integration and application of the SIMOTICS S 1FK7 synchronous servo motor and related DELTA electrical hardware in precision industrial automation contexts.