Register to unlock your exclusive B2B prices and start shopping. Sign up now!

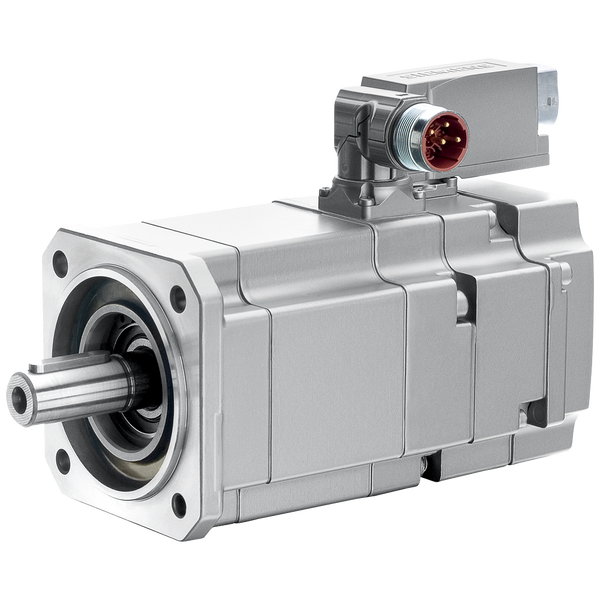

SIMOTICS S Synchronous servo motor 1FK7 Compact 0.85Nm, 100K, 6000rpm 0.38kW, Naturally cooled Power/signal connectors

Order only

Price (excl. VAT):

1 364,64 €

per pcs

EAN: 0662643005325

MPN: 1FK7022-5AK71-1DA0

Package: 1

Estimate delivery time at our warehouse (approx.):

4-6 weeks

Technical Information

| Item condition | New |

| Manufacture name | SIMOTICS S Synchronous servo motor 1FK7 Compact 0.85Nm, 100K, 6000rpm 0.38kW, Naturally cooled Power/signal connectors |

| Brand | Siemens |

| Categories |

Standard Electric Motors

|

| Country of origin* | RO |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8501 5100 00 |

| Rated current | 0 A |

| Rated voltage | 0 V |

| Rated performance at rated frequency | 0 kW |

Packing details

| Packing level 1 | 0662643005325 |

Other Technical data

| Number of phases | 0 |

| Number of poles | 0 |

| Rated rotational speed at rated frequency | 0 1/min |

| Frame size according to IEC | 0 mm |

| Full-load efficiency | 0 % |

| Starting current ratio | 0 |

| Starting torque ratio | 0 |

| Breakdown torque ratio | 0 |

| Voltage anti-condensation heater | 0 V |

| Output power anti-condensation heater | 0 W |

| With positive temperature coefficient resistor (PTC) | No |

| With resistance temperature detector (RTD) | No |

| Overload capability | No |

| Suitable for frequency control | No |

| With anti-condensation | No |

| Nominal torque | 0 Nm |

| Power factor | 0 |

Description

## Product Overview

The SIMOTICS S Synchronous Servo Motor 1FK7 Compact 0.85Nm integrates precision engineering for dynamic motion control applications. Key technical specifications are as follows:

### Torque and Speed Parameters

- **Nominal Torque (0.85 Nm):** Engineered for moderate torque output, suitable for precise servo positioning tasks without overload margin specifications.

- **Rated Rotational Speed (6000 rpm):** High-speed capability optimized for rapid response in closed-loop control systems, with no rated frequency or power factor data provided.

### Power and Cooling

- **Power Rating (0.38 kW):** Compact power output tailored for low to medium load applications, with natural convection cooling minimizing thermal management complexity.

- **Cooling Method:** Naturally cooled, relying on ambient airflow, limiting continuous operation efficiency under elevated thermal loads.

### Structural and Connective Elements

- **Frame Construction:** Aluminum-metallic frame variants (1-fold to 5-fold, dimensions from 80x80 mm to 364x80 mm) ensure mechanical robustness and electromagnetic shielding, facilitating integration into modular installations.

- **Power/Signal Interfaces:** Equipped with dedicated connectors for turnkey electrical integration, supporting reliable signal transmission and power supply continuity.

### Additional Components and Accessories

- **Fuse NH3 630A & DELTA Switches:** Protective circuitry employs robust NH3 fuses and DELTA switches for secure fault interruption and operational control.

- **Auxiliary Controls:** Pushbutton switches and LED lamp inserts enable direct manual operation and status indication within industrial control panels.

- **Specialized Accessories:** Includes antenna cover plates and rocker switches designed for universal switching applications within industrial automation frameworks.

### Limitations and Missing Parameters

- Absence of critical electrical data such as rated voltage, current, frequency, power factor, and efficiency metrics restricts in-depth performance evaluation.

- Lacks built-in anti-condensation features, overload capability, and suitability for frequency control applications, which may limit operational environments and dynamic load adaptability.

This servo motor’s technical architecture fits compact, naturally cooled low power servo drive systems requiring moderate torque output and extensive integration flexibility.