Register to unlock your exclusive B2B prices and start shopping. Sign up now!

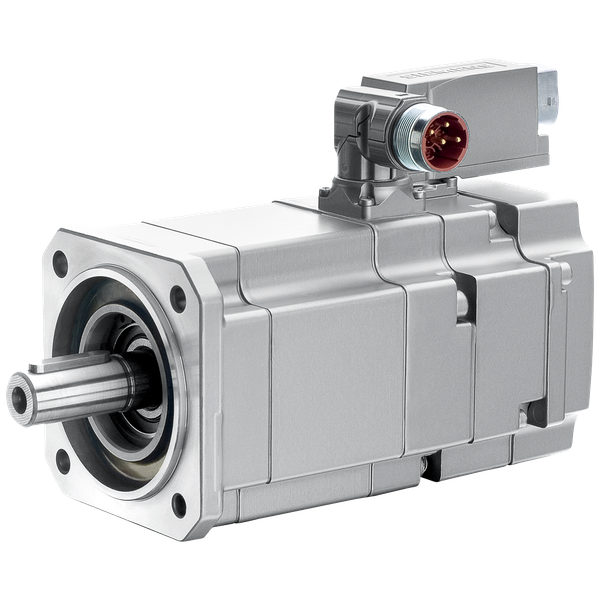

SIMOTICS S Synchronous servo motor 1FK7 Compact 0.35Nm, 100K, 6000rpm 0.10kW, Naturally cooled Power/signal connectors

Order only

Price (excl. VAT):

1 621,67 €

EAN: 0804766379383

MPN: 1FK7015-5AK74-1JH3

Package: 1

Estimate delivery time at our warehouse (approx.):

4-6 weeks

Technical Information

| Item condition | New |

| Manufacture name | SIMOTICS S Synchronous servo motor 1FK7 Compact 0.35Nm, 100K, 6000rpm 0.10kW, Naturally cooled Power/signal connectors |

| Brand | Siemens |

| Categories |

Standard Electric Motors

|

| Country of origin* | RO |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8501 5100 00 |

| Rated current | 0 A |

| Rated voltage | 0 V |

| Rated performance at rated frequency | 0 kW |

Packing details

| Packing level 1 | 0804766379383 |

Other Technical data

| Number of phases | 0 |

| Number of poles | 0 |

| Rated rotational speed at rated frequency | 0 1/min |

| Frame size according to IEC | 0 mm |

| Full-load efficiency | 0 % |

| Starting current ratio | 0 |

| Starting torque ratio | 0 |

| Breakdown torque ratio | 0 |

| Voltage anti-condensation heater | 0 V |

| Output power anti-condensation heater | 0 W |

| With positive temperature coefficient resistor (PTC) | No |

| With resistance temperature detector (RTD) | No |

| Overload capability | No |

| Suitable for frequency control | No |

| With anti-condensation | No |

| Nominal torque | 0 Nm |

| Power factor | 0 |

Description

## Product Overview

The SIMOTICS S Synchronous Servo Motor 1FK7 Compact (0.35 Nm, 6000 rpm, 0.10 kW) represents a precision-engineered electrical actuator optimized for high-dynamic closed-loop control applications.

### Torque and Speed Characteristics

- **Nominal Torque (0.35 Nm)**: Provides consistent torque output suitable for low-load, high-precision positioning.

- **Maximum Rotational Speed (6000 rpm)**: Enables rapid angular velocity, facilitating agile response in dynamic servo applications.

### Power and Cooling

- **Power Rating (0.10 kW)**: Reflects a low-power profile suited for compact machinery and automation systems with limited energy budgets.

- **Natural Cooling Method**: Relies on convection cooling, minimizing complexity but limiting extended high-load operation.

### Electrical and Mechanical Interfaces

- **Power/Signal Connectors**: Designed for reliable, noise-immune transmission of power and encoder signals essential in synchronous servo control schemes.

- **Aluminum-Metallic Frame Options (1- to 5-fold configurations)**: Provide modular mechanical mounting surfaces with robust thermal dissipation properties.

### Auxiliary Components

- **Fuse NH3 630A**: High-capacity overcurrent protection element designed for industrial-grade electrical safety.

- **DELTA Switches and Pushbutton Switches**: Facilitate manual operational control and status monitoring within control circuits.

- **LED Lamp Insert for Control Functions**: Enables optical status indication to support maintenance and diagnostics.

This servo motor system’s lack of frequency control suitability and absence of anti-condensation features indicate its targeted use in controlled, dry environments with stable operational parameters.