Schneider Electric Luminaires

Schneider Luminaires for professional projects

Specifiers looking for predictable photometry and long service intervals will find a coherent range for offices, retail, hospitality, and plant areas. Families cover linear trunking, recessed panels, downlights, high-bays, floodlights, and emergency variants—each with matched optics, drivers, and accessories. Typical electrical parameters: 220–240 V AC, PF ≥ 0.95, THD ≤ 10–15 %, surge protection 2/4 kV (line/line to earth), flicker index optimized for camera environments. Light engines meet LM-80 with TM-21 projections to L80/B10 ≥ 50,000–100,000 h, depending on model.

Product range and series overview

Linear systems ship in trunking and suspended forms with plug-and-play feeds and joiners. Recessed panels include micro-prismatic, lens, and low-UGR optics; downlights span 68–200 mm cut-outs with field-selectable CCT on some SKUs. Industrial bodies offer IP65/IK08–IK10 for dust, moisture, and impact; floodlights use rotatable brackets and asymmetric distributions for façades and yards. Options: DALI-2 or 1–10 V, on/off, corridor function, wireless room control bridges, and central or self-contained emergency (1 h/3 h). Photometric files (IES/LDT) and UGR tables are available to drop into your lighting calc workflow.

Lighting projects that span residential, commercial, and industrial requirements often combine multiple fixture families to balance aesthetics, durability, and cost efficiency. Decorative hospitality and home interiors frequently choose design-focused solutions from sollux luminaires, while modern offices and retail spaces rely on versatile, easy-to-install options from slv luminaires. Public buildings and technical infrastructure benefit from the performance and uniformity delivered by siteco luminaires, and budget-oriented commercial rollouts often include practical fixtures from shada luminaires. When durability in logistics centers or industrial halls is critical, engineers finalize the specification using robust solutions from schrack luminaires.

Technical specifications and standards

- CCT 2700–6500 K, SDCM ≤ 3 for colour consistency; CRI ≥ 80 as standard with CRI 90 options on selected interiors.

- Luminous efficacy commonly 110–170 lm/W by class; glare control optics achieve UGR ≤ 19 in compliant office layouts.

- Operating ambient −25…+45 °C typical; industrial high-bays up to +55 °C with thermal fold-back.

- Ingress per IEC 60598-1/-2; control per IEC 62386 (DALI-2); EMC per EN 61000-6-2/-6-3; safety labeling ENEC/CE.

- Tool-less gear trays and through-wiring kits on trunking reduce install minutes per luminaire run.

Where legacy gear remains, driver SKUs include fixed-output and dimming to match panel dimmers or BMS. For new builds, specify DALI-2 with group/scene logic to keep commissioning uniform across floors.

Schneider Industrial Lighting classes and optics

Warehouses, assembly lines, and process halls benefit from IP65 sealed linear battens and high-bays with narrow/medium/wide distributions. Lens options focus on racking aisles to lift horizontal and vertical illuminance without over-lighting walkways. Cable glands accept 1.5–2.5 mm²; through-wiring forms continuous runs with maintained IP. Ambient monitoring and step-dim profiles reduce heat load at low occupancy. Where corrosion or cleaning agents are present, pick polyester-powdered aluminum or stainless hardware and polycarbonate lenses rated for chemical resistance.

Applications and compatibility

Open-plan work areas use recessed or suspended lines to reach 500 lx at task with UGR control; labs and classrooms opt for micro-prismatic panels and local occupancy/daylight sensors. Atriums and retail deploy accent downlights and wall-washers; façades and signage rely on asymmetric floods. In all cases, the catalog aligns mechanically and electrically with Schneider control gear—contactors, dimmers, and DALI gateways—so schneider lighting fixtures plug into the same wiring logic as protection and switching tiers.

Schneider Architectural Luminaires for public and commercial spaces

Visual comfort and finish options matter in lobbies, galleries, and customer areas. Trimless and framed downlights ship in white, black, and metallic finishes; linear profiles accept continuous diffusers or micro-lens arrays for a clean ceiling. Colour consistency (SDCM ≤ 3) keeps long corridors uniform. For museums and retail, CRI 90 with R9 emphasis is offered; tunable white (2700–6500 K) supports circadian and branding scenes. Emergency blades and integration frames maintain a flat aesthetic without ad-hoc brackets.

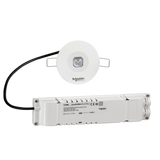

Control, drivers, and emergency integration

DALI-2 drivers expose energy and diagnostics; 1–10 V units serve legacy rooms. Scenes and schedules are handled in room controllers, while presence and daylight hold corridors at a safe baseline. Central battery versions include maintained/non-maintained circuits with test input; self-contained units provide auto-test logs for FM teams. Where surge environments are harsh, coordinate the luminaire SPD level with board-level SPDs to avoid overstressing drivers.

Selection criteria for B2B engineers

- Lux and glare: hit EN 12464-1 targets with UGR ≤ 19 where required; choose narrow optics for aisle racking to reduce spill.

- Colour and fidelity: CRI 80 for back-of-house; CRI 90 or R9-rich for retail/healthcare; consider tunable white for multipurpose rooms.

- Environment: IP65/IK10 in dusty or wash-adjacent zones; verify lens chemistry vs detergents and oils.

- Controls and wiring: DALI-2 for group/scene and analytics; 1–10 V where cost wins; wireless bridges where re-cabling is limited.

- Service model: tool-less trays, through-wiring kits, and standardized hangers cut install time; specify connectors and cord lengths up front.

Where human-centric layouts matter, planners often note schneider office lighting to communicate UGR and CCT policy to procurement and FM.

Procurement and documentation

Fix a per-space bill: luminaire type, lumen pack, optics, CCT/CRI, control protocol, emergency mode, suspension/trim kit, SPD class, and cordset. Request IES/LDT, UGR tables, and thermal/ambient curves with each line. For repetitive bays, lock trunking lengths and feed positions to keep joiners and live ends consistent; stock spare gear trays for the top movers in your fleet.

Advantages of working with Bankoflamps

Bankoflamps ties pricing to your room schedules and exposes real-time EU stock before you reserve installation windows. Quotes typically return in about an hour. Ordering by EAN/MPN prevents variant drift; your portal shows lead times, shipment status, and downloadable price lists. Approved partners can use post-payment up to 30 days. We consolidate partials to reduce freight and hold price-validity windows so phased fit-outs stay predictable. Your account manager cross-checks optics, drivers, control protocol, emergency options, and mounting kits against drawings—so pallets land complete and ready to hang.