Schneider Electric E-mobility

schneider e mobility platform for AC and DC deployments

Schneider’s EV portfolio is built for electrical contractors and fleet operators who want predictable installation rules and clean integration with protection, metering, and BMS/SCADA. AC wallboxes cover 3.7–22 kW (single/three-phase, 230/400 V); DC chargers span ~24–180 kW with scalable power stages. Enclosures typically meet IP54–IP65 and IK10; operating −25…+50 °C with thermal derating curves in the datasheets. Communications include Ethernet, Wi-Fi, 4G/LTE, and RS-485 as required by site policy. Standard authentication options are RFID, PIN, and backend tokens.

schneider ev charging systems AC wallboxes and DC fast chargers

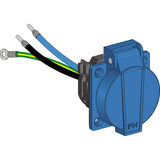

AC: Mode 3, IEC 61851-1 with Type 2 sockets/cables (IEC 62196-2). Integrated 6 mA DC leakage detection lets you pair upstream Type A 30 mA RCDs; where chargers do not include DC detection, specify Type B. MID/EN 50470 meters are available for cost allocation; OCPP 1.6J (select models 2.0.1-ready) connects to CPO backends. Dynamic load management (DLM) shares building capacity across chargers and priority tiers; phase balancing protects main incomers.

DC: CCS2 (IEC 62196-3) with isolated power modules, contactor pre-charge, and monitored earth. Typical surge coordination is Type 2 at the board plus internal MOV/TVS stages; check Up against local grid transients. Cable options include liquid-cooled sets for >200 A duty. HMI exposes charge state, error codes, and tariff class; OCPP events mirror into the site’s EMS.

schneider charging units installation standards and protection

Reference IEC 60364-7-722 for EV supply equipment and local DNO rules. Feeders are sized for continuous duty with diversity rules documented in the single-line. Upstream protection follows IEC 60947-2/60898-1 (MCB/MCCB/RCBO) and SPD per IEC 61643-11. Earthing and PEN-fault handling follow national codes; use PME-safe schemes or local earth electrodes where required. Cable management includes tethered Type 2 leads with strain relief, anti-twist couplers, and vandal-resistant holsters. For outdoor pads, specify stainless fixings, anti-condensation breathers, and rodent-resistant conduits.

System architecture, metering, and fleet load control

Group chargers on dedicated boards: incomer + SPD, MID meter per feeder or per charger, then RCBO/MCB rows. Use DLM to cap kW at the site level, allocate priority (e.g., pool vehicles over visitors), and time-slice overnight sessions. For depots with PV or BESS, EMS can shift charge windows and export schedules; tariff-aware charging trims OPEX on time-of-use grids. Where building services share the transformer, reserve kVA headroom and implement brownout ramp-down via OCPP smart charging profiles.

Connectors, cables, and mechanical options contractors reuse

Type 2 sockets with shutter kits or tethered 5/7 m leads cover most cars; CCS2 guns on DC pedestals ship with holsters and optional hose management booms. Pedestal, wall, and dual-port totems share bolt patterns and gland plates; that keeps core drilling and trench layouts consistent across sites. For coastal or wash-adjacent areas, select powder-coated aluminum or stainless skins and sealed HMI windows.

Applications and compliance notes by segment

- Commercial parking: dual AC units with MID metering and RFID; DLM keeps within building kVA.

- Fleet depots: DC pedestals 60–180 kW on priority queues; Ethernet to the CPO and EMS.

- Hospitality/retail: AC 11–22 kW with roaming via OCPP; branded bezels and cable management for public use.

- Residential blocks: load-sharing stacks on a common feeder; monthly statements per apartment.

In documentation, call out schneider electric vehicle solutions when procurement must match chargers, metering, and software under one vendor stack.

Integration with Schneider power and building platforms

Chargers land cleanly on Acti9/ComPact protection, Prisma/Spacial switchboards, and EcoStruxure-based BMS/EMS. OCPP gateways coexist with Modbus meters; room for future PV/BESS is reserved at the bus. Alarms (RCD trips, earth faults, over-temp) publish to SCADA; maintenance KPIs—connector actuations, fan hours, module temps—feed service plans.

Selection criteria for B2B engineers

- Duty and dwell: AC 7.4–22 kW for long-stay; DC ≥60 kW for quick-turn fleet bays.

- Grid and earthing: fault levels, PEN strategy, RCD type (A + 6 mA DC vs Type B).

- Backend and UX: OCPP version, RFID/apps, tariff rules, smart charging profiles.

- Mechanical/IP: IK10 street furniture, IP54–65, heater kits for cold sites, sun-shields for glass atria.

- Metering/Billing: MID class, per-socket metering, roaming support.

- Service model: swappable power modules, front access, spare connectors, and a documented firmware policy.

Advantages of working with Bankoflamps

We align project pricing to your one-line, expose live EU stock across warehouses, and return quotes fast—typically around an hour. Orders by EAN/MPN prevent variant drift; your portal shows lead times, shipment status, and downloadable price lists. Approved partners can use post-payment up to 30 days. We consolidate partials to cut freight and keep price-validity windows so phased rollouts stay predictable. Our engineers cross-check feeders, RCD/SPD coordination, DLM topology, OCPP settings, and pedestal hardware against your drawings so chargers arrive site-ready—no missing plates, tails, or licenses.