Schneider Electric Charging cable E-Mobility

Schneider EV Charging Cables specification and build

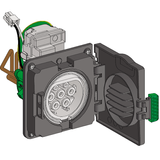

Contractors use this portfolio to connect AC wallboxes and DC pedestals with predictable thermal behavior, bend life, and connector endurance. Cable jackets are TPU/TPE for abrasion and oil resistance; indoor kits may use flexible PVC. Conductor sets cover single-phase 1P+N+PE and three-phase 3P+N+PE for 7.4/11/22 kW AC; DC sets use 2× power poles plus PE, with pilot/proximity cores per IEC 61851-1. Typical ambient −30…+50 °C, jacket ratings 90 °C continuous; IK08 grip housings and IP54/IP55 when mated (IP44 caps fitted when parked). Lengths 5/7/10 m are standard; spiral versions keep floor space clear in tight bays.

Schneider Type 2 Connectors options and safety

Type 2 (IEC 62196-2) plugs ship in open-end “cable only” for vehicle side, or with matching sockets for mobile EVSE kits. Silver-plated contacts hold low mΩ resistance over thousands of cycles; temperature sensors in the DC pins protect against overheated inlets. Mechanical latch + proximity (PP) and control pilot (CP) implement safe connect/disconnect; strain-relieved glands and molded grips survive daily fleet use. For harsh pads, stainless face plates and replaceable nose cones extend service life without changing the full lead.

Product range and current classes installers actually specify

- AC mode 3 leads: 16 A single-phase (3.7 kW), 32 A single-phase (7.4 kW), 16 A three-phase (11 kW), 32 A three-phase (22 kW).

- DC vehicle cables (CCS2): 150–300 A air-cooled sets for 24–150 kW pedestals; liquid-cooled options ≥400 A for higher-rate bays.

- Mechanical variants: straight or spiral, standard or slim-grip heads, replaceable dust caps, parking holsters, and anti-twist swivels.

- Data and control: shielded pilot pairs to reduce EMC issues near VFD rooms; molded PP/CP cores with color coding for quick QC.

Technical standards and verification

Conformance to IEC 62196-2/-3 (plugs, vehicle couplers), IEC 61851-1/-23 (EV supply equipment), and EN 50620/IEC 62893 (cable construction). Flammability and oil tests per jacket family; UV-stabilized black for outdoors. Contact heating tests validate ΔT at rated current; flex-life verified on <10× OD bend radius. All assemblies are hipot-tested and continuity-checked; serialization on boots aids asset tracking.

Applications and deployment patterns

Retail and hospitality sites carry 5–7 m 22 kW three-phase sets for mixed visitor cars; depots standardize 11 kW for overnight rotation. DC bays use high-amp leads with integrated strain-relief booms to keep handles off the ground. In multi-storey car parks, spiral AC leads reduce trip hazards; outdoor pads add anti-condensation breathers on holsters. For public use, bright color boots and large rating badges reduce misuse and speed bay turnover.

System integration with Schneider protection and metering

Leads park in rated holsters on Schneider pedestals; RCBOs on Acti9 rows protect the branch; SPD at the board limits let-through that would otherwise stress pilot electronics. MID meters and OCPP logs tie session kWh to lead IDs when fleets want traceability by parking position. Where cable drops pass through bollards, matching gland kits preserve IP and torque consistency across sites.

Selection criteria for B2B engineers

- Duty and current: choose 16/32 A AC by bay capacity; specify liquid-cooled DC only where session rates justify it—this is where a schneider high current charger cable is warranted.

- Environment: TPU/TPE and UV black outdoors; spiral for tight bays; stainless face plates in vandal-prone areas.

- Length and ergonomics: 5 m for wall-near bays, 7–10 m for shared islands; verify reach to rear/side ports.

- Thermal protection: require in-handle temp sensing on high-amp sets; check derating curves vs ambient.

- Serviceability: replaceable caps, nose cones, and holsters; serialized boots for inventory.

Procurement and kitting for rollouts

Fix two AC lengths (5 m and 7 m) in both 11 kW and 22 kW ratings; add one DC class per pedestal tier. Include holsters, anti-twist couplers, parking labels, and spare caps in each kit. Record lead IDs in the EMS so warranty and cleaning cycles are tied to bays. For residential blocks, bundle load-sharing labels and QR plates that link to usage policy—this keeps the schneider charging cable e mobility fleet consistent across tenants.

Advantages of working with Bankoflamps

You get project pricing tied to bay counts, live EU stock across warehouses, and fast quotes—typically near the one-hour mark. Orders by EAN/MPN prevent variant drift; your portal shows lead times, shipment status, and downloadable price lists. Approved partners can use post-payment up to 30 days. We consolidate partials to cut freight and lock price-validity windows so phased installs stay predictable. Our team cross-checks current class, length, jacket, holster style, and gland kits against your drawings so cables arrive site-ready—no missing fittings.