Overload Relays

Overload Relays for B2B Procurement and Wholesale Distribution

Introduction

In modern electrical systems, controlling and protecting motors is one of the most critical aspects of design, installation, and long-term operation. Motors account for a large share of industrial energy consumption, and their reliability directly affects productivity. To safeguard motors against excessive currents, overheating, or operational faults, overload relays remain an indispensable category in B2B electrical supply.

Unlike simple fuses or circuit breakers, which provide short-circuit protection, an overload protection relay focuses on thermal and current-based monitoring that reacts to sustained overload conditions. This ensures that motors can start under normal inrush currents but disconnect safely if abnormal loading persists. From a procurement perspective, an overload relay is not just another accessory—it is a decisive factor in extending motor life, minimizing downtime, and protecting investment in machinery.

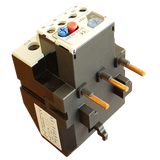

Over time, several variations of overload relays have developed to meet different industrial and commercial needs. The two most common are bimetallic overload relays and electronic overload relays. Bimetallic designs use the thermal expansion of metals to trip under overload, providing a cost-effective and proven method widely used in legacy installations. In contrast, electronic overload relays integrate precise current sensing, adjustable trip curves, and sometimes communication functions, making them suitable for modern automated systems. Procurement managers often source https://bankoflamps.com/abb-motor-protection-circuit-breakers alongside overload relays. This ensures both selective protection and precise motor performance monitoring.

Applications are not limited to large factories alone. Wholesale buyers distribute motor overload relays for HVAC systems, pumps, conveyors, lifts, packaging machines, and countless small and mid-scale installations across Europe. A single-phase overload relay might be used in small commercial applications, while an overload relay 3 phase protects industrial drives. Similarly, a contactor overload relay combination remains one of the most standardized assemblies in motor control centers (MCCs) worldwide.

For procurement managers, the decision to select the correct relay overload type depends on multiple factors:

- Motor ratings (current and voltage)

- Phase configuration (single-phase or three-phase)

- Trip class and reset options (manual/automatic)

- Integration with contactors or standalone usage

- Certifications and compliance with IEC or UL standards

- Lifecycle cost versus overload relay price at acquisition

B2B distributors handle not only product variety but also the logistical and regulatory aspects. A buyer evaluating motor overload relays in bulk must consider supply lead times, European stock availability, warranty coverage, and compatibility with regional standards. In an environment where downtime costs often exceed the hardware cost itself, the reliability of both the relay and the distributor matters equally.

This is why professional buyers turn to wholesale partners who can provide guaranteed stock, competitive overload relay prices, and technical expertise in selecting between bimetallic, electronic, single-phase, and three-phase models. The following FAQ section addresses the most common and practical questions raised by electrical contractors, project engineers, and procurement managers when sourcing overload relays through a distributor.

Frequently Asked Questions about Overload Relays

1. What is an overload relay and how does it differ from a circuit breaker?

An overload relay is specifically designed to protect motors against sustained overcurrent that causes overheating. Unlike a circuit breaker, which responds instantly to short-circuit faults, an overload protection relay allows for motor inrush currents and trips only if the current remains above rated levels for too long.

2. Which type of overload relay is better: bimetallic or electronic?

A bimetallic overload relay is cost-effective and suitable for standard motor applications where precision is less critical. An electronic overload relay, on the other hand, provides more accurate trip settings, better repeatability, and sometimes built-in diagnostics. Buyers in automation-heavy sectors often prefer electronic designs despite the higher overload relay price.

3. Can overload relays be used with both single-phase and three-phase motors?

Yes. A single-phase overload relay is intended for smaller motors or compressors, while an overload relay 3 phase is the standard choice in industrial motor control. It is essential to match the relay type to the motor’s electrical configuration.

4. What is a motor overload relay and where is it typically installed?

A motor overload relay is installed in series with the motor circuit, usually in combination with a contactor. Together, they form a contactor overload relay assembly, ensuring both switching and protection of the motor.

5. How do I know the correct relay overload setting for my motor?

Relay settings are based on the motor’s full-load current (FLC). For a relay overload device, the tripping range should cover approximately 1.0–1.2 times the FLC. In electronic models, this setting is adjustable, allowing finer tuning during commissioning.

6. Do overload relays require certifications for use in Europe?

Yes. For wholesale distribution within the EU, both motor overload relays and contactor overload relays must comply with IEC standards (such as IEC 60947-4-1). Many products also carry CE marking and, where required, UL/CSA approvals for export-oriented projects.

7. How fast can overload relays be delivered within Europe?

For stock items, distributors can usually dispatch overload relays within 24–48 hours across central Europe. For project-specific or non-standard models, lead times may extend to 2–4 weeks. European logistics networks ensure consolidated shipments for bulk procurement.

8. What is the typical warranty period on overload relays?

Most manufacturers and wholesale distributors offer a standard 12–24 month warranty on overload relays, covering material and manufacturing defects. Extended warranty terms may be available for electronic overload relays when purchased in bulk.

9. Are overload relays compatible across different brands of contactors?

Compatibility depends on mounting design and terminal layout. Many contactor overload relays are brand-specific, meaning a relay from one manufacturer is mechanically designed to fit its own contactor series. However, standalone relay overload devices can often be wired with multiple brands if electrical ratings match.

10. What factors influence the overload relay price?

The overload relay price depends on several factors:

- Current range (small relays for 0.5–5 A cost less than those for 100–200 A)

- Type (bimetallic models are cheaper than electronic overload relays)

- Phase support (single-phase overload relay versus 3 phase overload relay)

- Added features such as adjustable trip classes or communication ports

11. How do electronic overload relays improve motor protection?

An electronic overload relay continuously monitors current with high precision. It offers adjustable trip curves, sometimes phase-loss detection, and better repeatability compared to bimetallic overload relays. This makes them more reliable in protecting expensive motors in automated facilities.

12. What is the difference between delay tripping and instantaneous tripping in overload relays?

A motor overload relay is designed to delay tripping to allow for normal startup currents. Instantaneous tripping is handled by short-circuit devices like MCBs or MCCBs. The overload protection relay balances motor tolerance and protection against sustained faults.

13. Are there minimum order quantities (MOQs) for wholesale procurement?

Most distributors allow flexible MOQs. For project buyers, a box quantity of overload relays (typically 10–20 pieces) may be the minimum. For large-scale tenders, thousands of motor overload relays can be supplied under contractual schedules.

14. Can overload relays be reset manually after tripping?

Yes. Both bimetallic overload relays and electronic overload relays include manual reset options. Some models also support automatic reset, but this is less common in industrial safety applications.

15. Do overload relays require periodic maintenance?

Relay overload devices are generally low-maintenance. However, for bimetallic overload relays, calibration should be checked periodically. Dust, vibration, or high ambient temperatures may affect their long-term accuracy compared to electronic overload relays.

16. Are overload relays suitable for use in hazardous environments?

Specialized motor overload relays with ATEX or IECEx certification are available for explosive atmospheres. Procurement managers should verify compliance before ordering for chemical or oil & gas projects.

17. How do overload relays integrate into automation systems?

Advanced electronic overload relays can be connected to PLCs via auxiliary outputs. This allows monitoring of trip status, fault logging, and remote reset. Traditional contactor overload relays without electronics are limited to direct motor protection.

Conclusion

For wholesale buyers and electrical professionals, selecting the right overload relay is more than a technical choice—it is a procurement decision with direct impact on uptime, safety, and total lifecycle costs. From single-phase overload relays for commercial compressors to overload relay 3 phase solutions for industrial drives, the range of options is vast. Bimetallic versions remain a trusted low-cost choice, while electronic overload relays offer precise protection for modern automated systems.

As distributors, our role is to ensure consistent supply, competitive overload relay prices, and compliance with European logistics and certification requirements. Whether sourcing motor overload relays for small projects or negotiating framework contracts for multinational installations, we provide the technical and logistical backbone that ensures every motor runs safely, efficiently, and without costly interruptions.