OBO Bettermann Fixings

OBO Bettermann Mounting Systems in Industrial & Commercial Projects

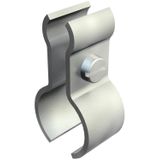

Every electrical, mechanical or structural installation requires reliable fixings—clamps, brackets, anchors and supports—that will hold cables, conduits, trays and heavy equipment in place for decades. OBO Bettermann’s fixing systems (mounting brackets, clips and anchors) deliver mechanical performance, consistent repeatability and standard-compliance. For example, their Quick® series of halogen-free cable and pipe clips emphasises short installation time, secure fastening and compatibility across multiple sizes.

From a procurement viewpoint: key parameters include load rating (kg or kN), material & surface treatment (galvanised, stainless steel A4, etc.), range of diameters/clamps, mounting height or spacing, and certification (e.g., V4A stainless in corrosive environments).

Technical Specifications & Product Families of OBO Fixings

- Pipe and conduit clamps (Quick® series): Available in adjustable clamping range, halogen-free, designed for indoor/outdoor use. The shared mounting contour allows stacking of up to three clips on one drill-hole, reducing installation labour.

- Cable brackets and tube fastenings: Example: item 5229839 — cable bracket for Rd 8–10 mm, mounting height 30 mm, female thread (G) with two hex bolts.

- Holders and fastenings for support structures: Wall and ceiling brackets, side holders, clamps made of steel or stainless, lengths from 12 mm–2000 mm, surface treatments including hot-dip galvanised.

- Bracket systems for external and lightning installations: E.g., VA cable bracket for isCon® conductor, for roof/wall mounting structures, with sprung discs to prevent screw loosening.

Procurement & Specification Checklist—What to Verify

- Material type & corrosion class: Indoor dry environment may allow strip-galvanised steel; outdoor or corrosive zones (coastal, chemical plant) require A4 stainless steel.

- Load and size compatibility: Fixing must support the weight of the conduit/tray plus dynamic loads (vibrations, thermal expansion). Confirm manufacturer’s load table.

- Mounting height and geometry: Example: clamp installed height 30 mm for Rd 8-10 mm bracket. If installed height is greater or substrate is different, performance may change.

- Spacing & support layout: Use recommended spacing (e.g., every 1.5–2 m for pipe runs) to meet mechanical code and avoid sagging.

- Certification and fire-safety: Clips in certain zones may need halogen-free certification (e.g., for evacuation routes). Quick® series emphasises halogen-free.

- Standardisation across the project: Selecting one family of fixings (OBO Quick®, standard brackets) reduces spare-parts variants, simplifies procurement, and lowers training cost.

Failure to check these may lead to increased repeat labour, non-compliant installation and higher maintenance cost.

Practical Examples & Cost-Justification

- In a commercial fit-out installing 1 000 pipe clamps: choosing Quick® adjustable clip reduces drilling holes by ~33% (three clamps per hole). Labour cost saved: assume 5 minutes per clamp vs 3 minutes per hole – savings of ~1 000×(5–3) = 2 000 minutes (~33h) at labour cost €45/h → ~€1.5k savings.

- In an industrial plant subject to corrosion: choosing A4 stainless fixings prevents rust/maintenance every 3-5 years vs standard galvanised—reducing downtime and lifecycle replacement cost.

Why Using OBO Bettermann Fixings Makes Operational Sense

When you standardise your installation fixings on OBO across trays, pipes, conduits and external mounts, you gain:

- Fewer part-numbers, simplifying spares inventory

- Consistent mechanical behaviour, enabling predictable installation planning

- Trusted manufacturing and specification data for compliance and auditing

For large-scale roll-outs, this standardisation often reduces installation variations, improves maintenance efficiency and gives procurement better bulk-pricing leverage.

B2B Supply & Wholesale Support via Bank of Lamps

Working through Bank of Lamps grants full procurement-oriented access to OBO Bettermann fixing systems with professional support:

- Volume-based pricing tailored to your order size and repeat-order cycle.

- Dedicated account manager familiar with fixing systems and specification details.

- Real-time stock visibility across central and partner warehousing—critical for multi-zone installations.

- Quotation turnaround typically within one hour—helpful when tender deadlines are tight.

- Ordering via EAN/MPN lists to ensure accuracy in multi-line orders with minimal entry error.

- Downloadable spec sheets, load tables, material finish codes, installation guidance accessible for design/procurement teams.

- Tracking of order from point-of-order to dispatch and delivery.