OBO Bettermann Cable clamps

604 20 G Fastening clip single lobe 20mm

604 16 G Fastening clip single lobe 16mm

604 25 G Fastening clip single lobe 25mm

3050 LGR Pressure ISO clip 6-16mm

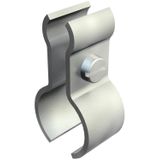

605 16 G Fastening clip two lobe 16mm

605 20 G Fastening clip two lobe 20mm

1015 D 12 G Fastening clip for 2 cables 12mm

1015 D 20 G Fastening clip for 2 cables 20mm

1015 D 18 G Fastening clip for 2 cables 18mm

822 10 FT Fastening clip single lobe 10mm

822 20 FT Fastening clip single lobe 20mm

822 40 FT Fastening clip single lobe 40mm

822 63 FT Fastening clip single lobe 63mm

605 16 A4 Fastening clip two lobe 16mm

SB MS 41 M8 FT Clamp

2056RS M 40 FT Clamp clip with metal pressure sump 34-40mm

2056RS M 16 FT Clamp clip with metal pressure sump 12-16mm

2056 E 31 FT Clamp clip for 3 single-wire cables 28-31mm

1020 18-28 G Tensioning wire clip for cable 4-9 mm 19-28mm

328 1 Beam clamp with retaining spring 5-11mm

328 2 Beam clamp with retaining spring 10-19mm

SSP 6-21 M6 A2 Beam clamp heavyweight design 6-21mm

SSP 20-40 M6 FT Beam clamp heavyweight design 20-40mm

SSP 20-40 M6 A2 Beam clamp heavyweight design 20-40mm

1015 D 6 G Fastening clip for 2 cables 6mm

1015 D 5 G Fastening clip for 2 cables 5mm

1015 D 9 G Fastening clip for 2 cables 9mm

1015 D 10 G Fastening clip for 2 cables 10mm

1975 16-19 Snap clip 16-19mm

1974 16-23 Plug-in clip single 16-23mm

1975 12-15 Snap clip 12-15mm

255 17.5 LGR Fastening clip 17,5mm

255 12.5 LGR Fastening clip 12,5mm

Distance clamp with thread M6 10.5-12mm, St, GTP

BS-RS1-M-22 FT Clamp clip 2056 16-22

BS-H1-M-58 FT Clamp clip 2056 52-58mm

BS-H1-M-34 FT Clamp clip 2056 28-34mm

BS-H3-K-46 FT Clamp clip 2056 triple 40-46mm

BS-H1-K-58 A2 Clamp clip 2056 52-58mm

BS-H1-K-40 A2 Clamp clip 2056 34-40mm

BS-H1-K-70 A2 Clamp clip 2056 64-70mm

BS-H2-K-22 ALU Clamp clip 2056 double 16-22mm

BS-H1-K-46 A2 Clamp clip 2056 40-46mm

BS-H1-K-76 A2 Clamp clip 2056 70-76mm

BS-H1-K-40 ALU Clamp clip 2056 34-40mm

BS-H2-K-34 ALU Clamp clip 2056 double 28-34mm

BS-H3-K-28 ALU Clamp clip 2056 triple 22-28mm

BS-H1-K-52 ALU Clamp clip 2056 46-52mm

BS-H2-K-40 ALU Clamp clip 2056 double 34-40mm

BS-H2-K-58 ALU Clamp clip 2056 double 52-58mm

BS-U1-K-46 A2 Clamp clip 2056 40-46mm

BS-U1-K-70 A2 Clamp clip 2056 64-70mm

BS-U1-K-22 A2 Clamp clip 2056 16-22mm

BS-U1-K-40 A2 Clamp clip 2056 34-40mm

BS-U1-K-12 ALU Clamp clip 2056 08-12mm

BS-U1-K-70 ALU Clamp clip 2056 64-70mm

BS-U1-K-64 ALU Clamp clip 2056 58-64mm

Why OBO Cable Clamps Matter in Professional Installations

Cable-management in commercial, industrial and data-centre installations isn’t just about holding cable bundles—it’s about ensuring mechanical stability, compliance with code, thermal safety and future-proof serviceability. OBO Bettermann’s cable clamp portfolio, including the Quick® and clamp-clip series, is engineered for these demands: high load capacity, broad clamping ranges, material variety (aluminium, steel, stainless, plastic) and system-compatibility for profile rails and rails

In procurement or specification work: you’ll want to check clamping range, base type (N-foot, U-foot, H-foot, etc.), material/finish (galvanised, stainless A2/A4, aluminium), load rating, mounting interface and compatibility with your support structure (C-rail, flat iron, round profile). Overlooking one of these can cause mechanical failure, increased labour or non-compliance.

Key Technical Specifications & Selection Parameters

Clamping Range & Load Capacity

- Example: OBO Quick® pipe/cable clips support diameters from 15.5 mm to 63 mm and offer extraction forces up to 230 N in standard clips.

- Another benchmark: clamp clip portfolio shows clamping diameter min 4 mm up to 100 mm, across material families.

Key question: for your bundle diameter + future growth, choose clamp that covers full range rather than one that’s just “barely” sized.

Mounting Base Types & Structural Support

- The portfolio lists six base types: N, H, U, W, F, RS – each suited for distinct attachment geometry (profile rail, flat iron, round support).

- Mounting screws: the same head (WAF10) for all screws (M6/M8) as standardised by OBO. Ensures fewer tool types on site

Specification tip: Match base type to your support steelwork or rail system so installation is efficient and secure.

Material & Corrosion-Resistance

- Materials include aluminium (ALMg3), steel (galvanised), stainless steel A2, stainless steel A4

- Example price/variant listings: a polypropylene (PP) base clamp clip (Typ 2962) for conduit Ø20 mm, mounting hole Ø4.2 mm.

Purchasing guidance: For indoor dry environments galv-steel may suffice; for coastal or chemical plants choose A4 stainless for longevity

Fire-Safety, Certifications & Installation Efficiency

- OBO clamp clips support electrical function classes E30 to E90 (i.e., they can be used in fire-rated installations).

- Reduced drill operations: special combined-mount base allows up to 3 clips on one drill-hole (less labour)

Procurement note: Labour savings from fewer fixings + faster installation can reduce overall install time significantly.

Appication Scenarios & Practical Buyer Insights

Scenario: Large Commercial Fit-Out (Cable Run Bundles)

Suppose you have cable bundle runs of Ø45 mm along support rails every 1.5 m. Select OBO clamp-clip size that covers 40-50 mm, material finish hot-dip galvanised, base type N-foot for standard C-rail. Use 4 m span per support, with extraction capacity >230 N to allow for future cable additions.

Benefit: you will minimise number of variants, simplify spares, ensure mechanical safety and avoid re-drilling.

Scenario: High-Corrosion Industrial Plant

In a chemical or coastal environment, choose OBO clamps in stainless steel A4 with metal pressure-sleeve variant. Clamping range should allow future upgrade (e.g., up to 63 mm) and base type U-foot for flat steel iron. This avoids early replacement due to corrosion.

Cost justification: While initial cost is higher, lifecycle cost is lower (replacements, downtime) and risk of bundle slack or sag is reduced.

Scenario: Retrofit of Data Centre Cable Trays

Data centre installs often have dense wiring and require high airflow and minimal cable sag. Use OBO Quick® clips that fit trays, allow stacking of 3 clips per hole, reduce drill count, and clamp non-proprietary sizes (e.g., adjustable 15–37 mm)

Procurement benefit: Lower labour cost, less variant inventory, higher installation speed.

Specification Checklist for Your Procurement Pack

Before placing bulk orders of OBO cable clamps, ensure you have specified:

- Clamping range (min-max Ø) in mm

- Base type (N-foot, H-foot, etc) suited to your rail/support

Material & finish (galv steel, stainless A2/A4, aluminium, PP)

xtraction force or load rating in N

- Fire-safety rating if required (E30/E90)

- Mounting hole size & tool type (e.g., M6/M8)

- Compatibility with profile rails or flat steel supports

- Stock continuity/spares availability across your project lifecycle

Failing to ensure one of these often leads to install delays, mismatch, increased labour or non-compliance.

Why Standardising on One Brand (OBO) Adds Strategic Value

Large-scale roll-outs (commercial buildings, campuses, industrial sites) benefit from standardising on OBO clamps because:

- Single brand = single supplier, fewer SKUs, simplified training

- Consistent mechanical behaviour simplifies maintenance and replacement

- Bulk purchase and spare-parts stock simplification leads to cost savings

- OBO’s documented specification data and product continuity reduce risk of obsolescence

For procurement teams managing thousands of fixings, this becomes a low-risk choice both operationally and financially.

Wholesale & Project-Supply Terms via Bank of Lamps

Working with Bank of Lamps for OBO cable clamps brings professional B2B-support and terms:

- Volume-based pricing tailored to project size and repeat orders

- Dedicated account manager for specification guidance, lead-time coordination and delivery planning

- Real-time stock visibility across central and partner warehouses—critical for large roll-outs

- Quotation turnaround typically within one business hour to satisfy tight procurement timelines

- Ordering via EAN/MPN list to ensure accuracy with high-line counts