OBO Bettermann Cable bearing systems

OBO Cable Tray Systems: Basic Overview

Cable-routing is a foundational element in any commercial or industrial electrical/intelligent-installation project. OBO Bettermann’s cable-bearing systems provide structured pathways for power, control and data cabling — covering screw-mounted trays, wire-mesh trunking, ladder systems and full accessory ecosystems. As the manufacturer states: “A range of variants for every installation challenge ... high load-bearing capacity, simple installation, verified quality.”

These systems support installation reliability, cable maintenance access, future expansion and compliance with installation standards (e.g., DIN EN 61537, VDE requirements for cable support systems) as per OBO’s documentation.

System Variants: Technical Specifications & Use-Case Fit

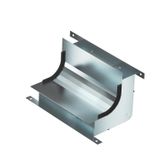

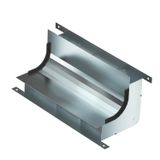

Screw-On Cable Tray Systems

These are the classic tray systems providing rigid support for moderate load. For example the “EKS 60 FS” variant: length 3000 mm, width 100–600 mm, side height 60 mm, strip-galvanised steel, plate thickness ~2 mm.

Use-case: office fit-out, data centre horizontal ladders, mechanical zones with moderate cable mass.

Wire-Mesh / Mesh Cable Tray Systems

OBO’s mesh trays (GR-Magic®, SGR, etc.) are particularly suited where airflow, visibility, frequent branching and light-weight installation matter. For example: the SGR 55 series uses spot-welded wire (Ø 6 mm) with side-height 55 mm and supports wider spans up to 4.0 m and higher load capacities.

Use-case: raised-floor telecom/data rooms, false-ceiling lighting infrastructure, retrofit-friendly cable routing.

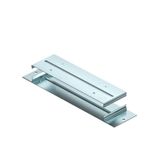

Light-Duty / Suspension / Access-Trays

The LKS light-duty system: side-height 60 mm, widths 100–600 mm, strip-galvanised for corrosion resistance. &#turn0search3 shows the specification.

Use-case: branch distributors, secondary cable routing in cabinets, service corridors.

Key Specification Metrics to Compare

When selecting OBO cable-bearing systems, the procurement or engineering team should verify:

- Load-bearing capacity: e.g., for EKS 60 FS width 100 mm the load at support spacing 2.0 m ~2.2 kN/m.

- Widths & side-heights: trays available width 100–600 mm, side-height from 35 mm upwards.

- Span between supports: mesh systems allow support spacing up to 4.0 m in some cases (SGR types) with adequate load.

- Material & surface treatment: steel (strip-galvanised FS), hot-dip galvanised FT, stainless steel A2/A4 — depending on environment (indoor, outdoor, coastal).

- Accessories & modularity: standardised fittings, plug-connections (Magic®), combinations of bends, tees, transitions — these speed installation and reduce labour.

- Compliance / test certificates: systems tested according to Snap-in lab (BET Test Centre) for mechanical and electrical safety.

Failing to check one of these can result in over-specification (higher cost), under-supporting (structural failure), or poor expandability.

Practical Procurement & Installation Advice

- Future-proofing cable volume: dimension tray width for 20-30 % expected growth in cable quantity; undersizing leads to costly re-routing.

- Thermal/airflow in mesh trays: mesh allows heat dissipation and cleanliness (less dust retention) — ideal for data-centres.

- Installation speed vs cost: plug-connection systems (Magic®) reduce installation time, labour cost, especially in retrofit or fast-track builds.

- Uniform system family across zones: Using one brand, one system family (OBO Modul45®, Magic trays, supports) simplifies spares, training, documentation.

- Earthing/grounding & bonding: Ensure tray supports bonding if carrying metallic cable armours or earthing conductors per standards.

- Environment-specific surface treatment: For coastal or chemical plants, choose A4 stainless; for standard dry indoor, strip-galvanised may suffice.

In practice, procurement teams that base decisions on these factors avoid major mid-project changes and maintenance-cost escalations.

Why Standardising on OBO Adds Value

Deploying OBO cable-bearing systems throughout an installation infrastructure brings these strategic advantages: fewer SKUs for spares, consistent mechanical/installation performance, interoperability of accessories, reduced training. Maintenance teams appreciate that support spacing, load ratings, accessories and identification are uniform. This simplifies long-term operations.

Supply & Project Terms with Bank of Lamps

When sourcing OBO cable-bearing systems via Bank of Lamps, you benefit from:

- Volume-tier pricing structured around roll-out scale, repeat phases.

- Dedicated account manager to coordinate specification records, BIM/CAD support, delivery scheduling.

- Live stock visibility across warehouses to support phased roll-out

- Rapid quotation turnaround (~1 hour) to align with tender deadlines.

- Ordering via EAN/MPN spreadsheets for accuracy in multiple line-items.

- Downloadable spec sheets (load tables, material options, accessory lists).

- Consolidated shipping of trays, supports, accessories to reduce freight cost and packaging.

- Freight cost estimate before dispatch; final cost confirmed ahead of shipment.