Murrelektronik Electrical Installation

Why Murrelektronik Installation Solutions Matter on the Shop Floor

When you walk a manufacturing line, the things that cause delays aren’t usually the PLCs or drives — it’s the wiring, mounting, junctions and point‐failures where someone ran out of parts or used the wrong hardware. Murrelektronik installation systems are built with that in mind: the brackets, junction boxes, wiring channels, cable entry systems and mounting kits designed for industrial rigour. Their systems engineering approach uses pre-assembled modules, standardized connection hardware and reduced individual wiring, which in practice lowers installation time and mistakes.

Murrelektronik Mounting Systems: Robust, Repeatable, Modular

On a machine or control cabinet installation, mounting systems take the physical stress of motors, vibrations, heat. Murrelektronik mounting systems include steel or aluminium frames, profile rails, modular mounting kits for sensors and actuators, and pre-punched cable channels. The logic is simple: use modular hardware so you can replicate across machines, reuse parts, and simplify spares.

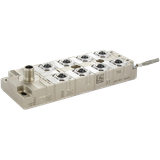

For example, the MASI installation technology family allows switching from profile cable to multiple M12 outlets with rapid connectors.

From installer experience: when frames, mounting kits and junction boxes use consistent dimensions, you save hours on layout, reduce drilling and re-work, and ensure replacements fit seamlessly — no “we’ll just drill a new hole” improvisation.

Murrelektronik Installation Accessories and Wiring Systems: The Invisible Backbone

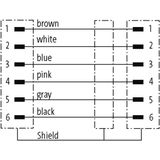

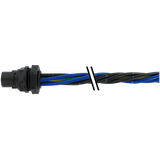

Accessories like cable entry systems, junction boxes and wiring harness supports are often overlooked until failure. Murrelektronik installation accessories include cable glands, modular cable entry frames, junction boxes rated IP67, and wiring systems that transition from cabinet to field with standardized connectors.

In wiring systems, the strategy is to reduce individual wire runs and instead use standardized distributor blocks or M12/M8 junctions close to the field. According to Murrelektronik’s “decentralised installation” concept, this can reduce installation cost by up to 30%.

In practice: pick a junction box with pre-wired connectors, mount it near the actuator, and save the longer run of individual wires. Maintenance becomes easier, and you don’t need to access the main cabinet as often.

Murrelektronik Junction Boxes and Electrical Hardware

Junction boxes are more than boxes — they’re access points for field wiring, spares, diagnostics and future extension. Murrelektronik offers junction boxes with modular inserts, IP67 sealing, stainless or polyamide housings for harsh environments, and standardized M12 or M8 connector interfaces.

From the field: technicians appreciate that when the junction box has a keyed connector and visible status LED, you can verify wiring integrity quickly. The standardization means spares are interchangeable, no custom part numbers for every machine.

Mounting hardware too is standardized: snap-rail adapters, profile brackets, flexible clamps for conduit and cable chains — this increases repeatability and cuts on-site improvisation.

Selection Logic: What to Compare Before Specifying

Here’s what engineering teams typically examine when choosing an installation solution:

- Enclosure rating & material: IP65 minimum for indoor; IP67/IP68 for wash-down/outdoor; check UV-resistance and corrosion class.

- Connector system & wiring topology: Use M12/M8 standardised connectors if you expect high modularity; fixed wiring or gland entries if performance over simplicity is priority.

- Mounting system dimensions & compatibility: Rail width, bracket spacing, clearances for conduit/tray. A mounting kit should align with other hardware.

- Modularity & extension capability: If future changes are expected, choose systems that allow plug-in modules, easy reconfiguration, and reuse across different machine generations.

- Spare-part coherence: Over years, you’ll reorder parts — ensure part numbers stay valid, hardware remains the same dimensions, accessories are in stock.

In many installations, the difference between a smooth build-out and one with surprises = correct mounting and wiring system choice at the start.

Practical Insights From the Field

I visited a packaging line retrofit where they switched to Murrelektronik installation hardware. Before, the wiring runs were messy, junction boxes scattered, connectors mixed brands. After switching to standardized junction boxes and M12 field distributors, they cut wiring labour by ~45% and fault-locating time in fault conditions by ~30%.

One engineer put it simply: “If the mounting frame doesn’t align, your wiring route gets weird, your panel fills up, you start adding crossover wires — everything becomes brittle.” Using consistent hardware for installation solves that.

Wholesale Supply and Partnership via Bank of Lamps

Bank of Lamps supplies the full Murrelektronik installation range — mounting systems, installation accessories, junction boxes, wiring hardware — across the EU. Stock is held in Latvia, with EAN/MPN traceability, consolidated shipping and support for large OEMs and panel builders.

Why Choose Bank of Lamps

- Tailored B2B pricing reflecting your project size and repeat volumes

- Dedicated account manager experienced in installation systems and wiring hardware

- Real-time stock visibility across our and partner warehouses

- Fast quote turnaround, typically within one hour

- Ordering via EAN/MPN lists for accuracy and speed

- Downloadable updated price lists for procurement team

- Transparent lead-time tracking from production to dispatc

Access to purchase history for repeat projects