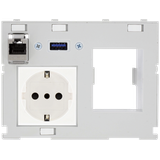

Murrelektronik Electric box (breaker panel)

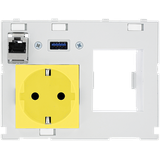

Murrelektronik Distribution Boards for Industrial Power Layouts

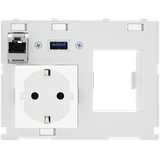

When you design a control cabinet or power distribution section, the board layout defines how clean, serviceable and expandable the system will be. Murrelektronik distribution boards are built with industrial logic: they allow field wiring, modular inserts, power feeders and maintenance access without compromising panel integrity. These boards aren’t simply metal boxes—they’re part of a system where switchgear enclosures, modular panels and electrical boards come together to serve the plant floor rather than just fill space.

For example, Murrelektronik’s distribution board modules support pre-wired or homerun cable systems, compact footprints and efficient insertion of I/O, protection, and bus interfaces. Using them means fewer custom panels, fewer field modifications, and lower labour costs over the lifetime of the installation.

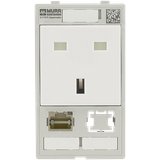

Murrelektronik Control Cabinets and Switchgear Enclosures

A common mistake is treating a control cabinet as a generic box. With Murrelektronik control panels and switchgear enclosures, you get features tailored to machine-room or factory-floor demands: the right ventilation, screw-less hinges, compatible busbars and modularity. The modular panel concept lets you configure sub-sections (power input, protection, automation, communication) as blocks that fit together.

In practice: you could build a chassis where protection breakers feed a Murrelektronik modular panel, then a sealed I/O node or distribution board module. The advantage: maintenance teams swap out entire sub-panels rather than rewiring everything. Over years, that adds up to uptime savings.

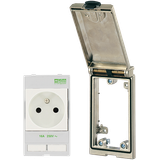

Murrelektronik Modular Panels and Installation Boards

Modularity is the keyword. Murrelektronik modular panels and electrical boards support layouts where expansion (new sensors, drives, safety circuits) is expected. Panels are designed with standard rail spacing, busbar mounts, and cut-outs for field distribution modules, making retrofits straightforward rather than chaotic.

One installer I spoke with said using Murrelektronik panels reduced their redesign time when capacity increased by 30 % — they simply added another module block into the board rather than starting from scratch.

Key Technical Aspects to Compare

When specifying Murrelektronik distribution boards or modular panels, consider:

- Board footprint & mounting compatibility: Panel height, internal depth, door opening clearance.

- Busbar layout & segregation: Does the board allow separate sections for mains, control, and communications? Are the busbars rated for the expected load?

- Cable entry & segregation: Field wiring trunking, gland plates, cable troughs. The board must accept multiple cable entries while maintaining integrity.

- Protection and serviceability: Is there space for modular protective devices (MCBs, modular breakers)? Are spares accessible? Are there pre-wired blocks like Murrelektronik distribution modules?

- Expansion and spare capacity: Most rational panels leave 20-30 % spare module space — critical when operations expand.

- Standards and certifications: Panels should meet IEC 61439, UL 508A (if exported), and include documentation for audit/tracing.

Why Murrelektronik Adds Value in Real Projects

From field work, the difference between “just a board” and a well-engineered distribution layout emerges when you redo or service the panel. Murrelektronik’s approach means: same part numbers, compatible blocks, repeatable installation frames, fewer surprises when parts change.

Also, when a machine-builder delivers 50 cabinets to a plant, using a standard modular panel and board from Murrelektronik means the plant engineer can standardise maintenance spares, unify labelling, and avoid vendor-specific differences. Fewer varieties = fewer mistakes.

Wholesale Supply via Bank of Lamps

Bank of Lamps stocks the full Murrelektronik range of distribution boards, modular panels, switchgear enclosures and installation boards for Europe. Our logistics centre in Latvia supports OEMs, integrators and panel-builders with consolidated shipping, batch traceability and large-volume supply.

Why Choose Bank of Lamps

- B2B pricing tailored to your project volume and annual framework

- Dedicated technical account manager familiar with complete cabinet solutions

- Live stock visibility from our and partner warehouses

- Quotation turnaround typically within one hour

- Ordering via EAN/MPN lists for accuracy and speed

- Updated trade price files accessible for procurement teams

- Transparent lead-time tracking from factory to dispatch

- Purchase-history access for repeated builds and maintenance planning

- Deferred payment terms (up to 30 days) for approved clients

- Consolidated shipping across mixed product families to reduce freight c