Catalog

Cables and wires

Conventional Lamps

Electrical Installation

Show All

Alarm and security systems

Automation & Control Devices

CEE Plugs, Sockets and Combinations

Cable Management

Data and telecommunication

Door and Gate Hardware

E-mobility

Electric box (breaker panel)

Junction Boxes

Lighting protection

Mounting materials

Power supply elements and devices, reactive power compensation

Related Installation Materials

Switch Disconnectors

Tools, measuring instruments and protection

Off-load Switches

Heating, Cooling & Ventilation (HVAC)

Show All

Accessories (ventilators, pumps and gate operators)

Air freshener

Boilers and heaters

Cooling systems

Fans

Filters/separators

Heating appliances

Industrial fans

Trace heating cables and electric surface heating

Ventilation Ducting & Components

Air Curtains

Air Grilles & Diffusers

Pump Systems & Units

Industrial Automation

LED lamps and tubes

Lighting accessories

Luminaires

Show All

Emergency luminaires and accessories

Explosion proof luminaires

Flashlights, batteries and acessories

Industrial lights

LED Panels and accessories

LED strips, modules, profiles and accessories

Linear and modular luminaires

Street and park luminaires

Track lights and accessories

Built-in mounting lamps

Ceiling mounting lamps

Festive lightings

Floor lamps

In-ground luminaires

Machine and work bench luminaire

Pendant lights

Recessed lights

Surface mounting lamps

Table lamps

Wall mounting lamps

Renewable Energy

Switches and sockets

Register to unlock your exclusive B2B prices and start shopping. Sign up now!

- Home /

- Switches and sockets /

- Accessories (switches & sockets) /

- Holder plate LS93HP

- Home /

- Electrical Installation /

- Automation & Control Devices /

- Accessories & Spare Parts /

- Holder plate LS93HP

- Home /

- Jung +

- Switches and sockets /

- Jung Switches and sockets +

- Accessories (switches & sockets) /

- Holder plate LS93HP

- Home /

- Jung +

- Electrical Installation /

- Jung Electrical Installation +

- Automation & Control Devices /

- Jung Automation & Control Devices +

- Accessories & Spare Parts /

- Holder plate LS93HP

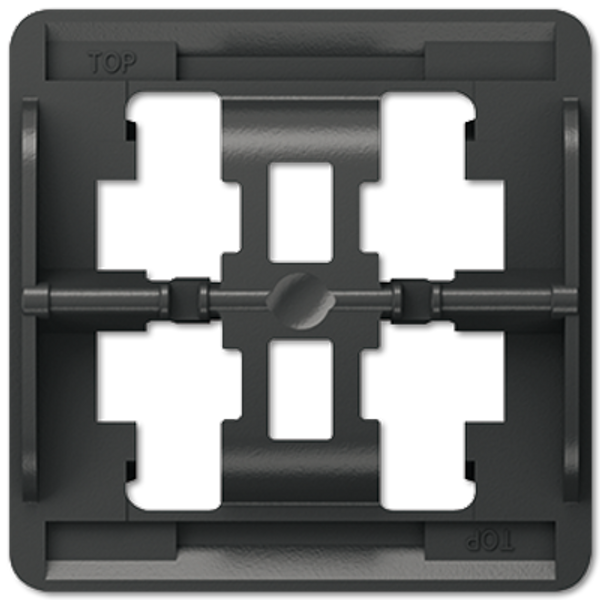

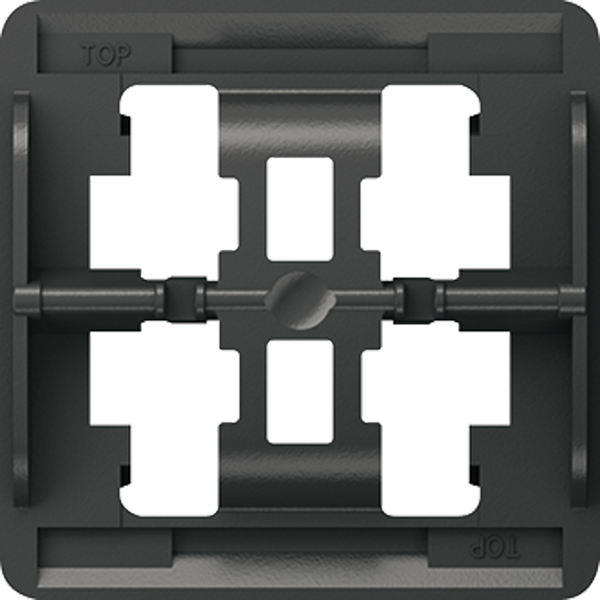

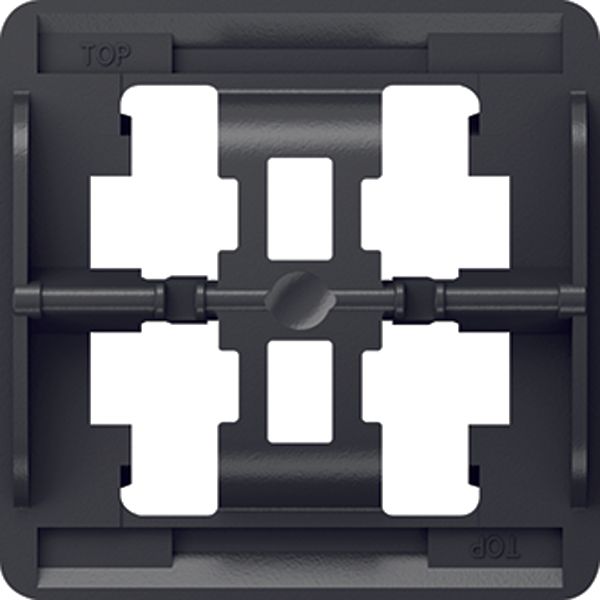

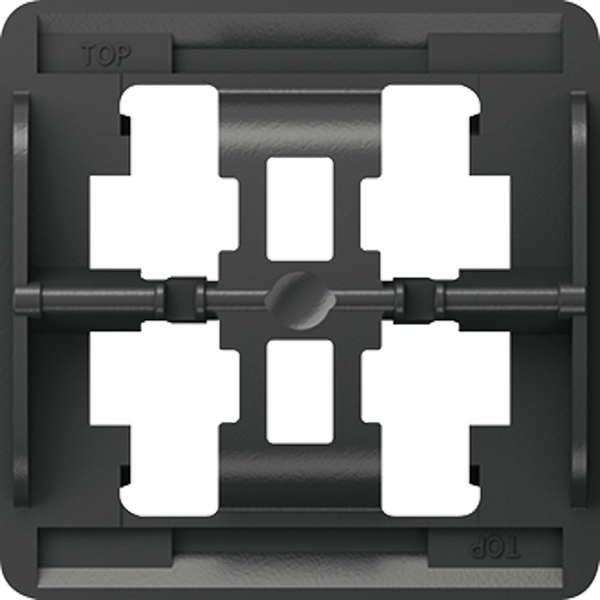

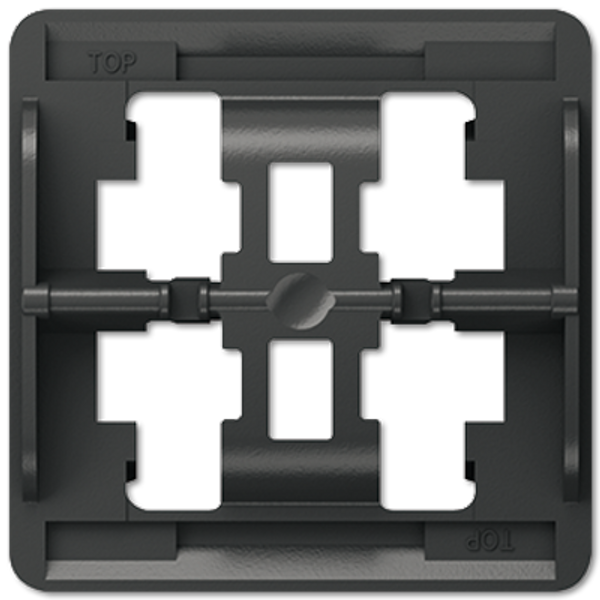

Holder plate LS93HP

Order only

Price (excl. VAT):

8,28 €

EAN: 4011377149182

MPN: LS93HP

Box: 1

Estimate delivery time to our warehouse: 2-4 weeks

Technical Information

| Item condition | New |

| Manufacture name | Holder plate LS93HP |

| Brand | Jung |

| Categories |

Accessories (switches & sockets)

Accessories & Spare Parts |

| Country of origin* | DE |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8538 9099 00 |

Packing details

| Packing level 1 | 4011377149182 |

| Packing level 2 | 4011377149182 |

Downloads

Description

Holder plate LS93HP is designed for mounting and securing components in switches or socket assemblies.Provides a stable base for proper alignment and operation within power delivery systems. Material indicates robust durability suited for electrical housing structures.Physical dimensions unclear but compatible with standard LS series configurations;check alignment tolerances before install.Expected load-bearing characteristics align with accessory-class designations under product category "switches & sockets". Evaluation of modular compatibility required—verify against known switchgear components via direct interface testing during assembly phase.Data insufficient regarding insulation properties—assume general conformity to standard dielectric compliance;further inspection advised at connection junctions.Manufacturer-supplied designation suggests role primarily as an anchoring mechanism within multi-point wiring frames, secondary tasks may involve grounding stability dependent on broader system layout specifics (unverified).End-use requires validation directly in system mock-up to confirm mechanical fitment remains consistent under operating stress points typically found in low-to-mid voltage networks.Proceed to physical prototyping or comparative fitting trials pre-deployment schedule recommended where exact tolerancing not yet demonstrated analytically.Confirm final housing pressure contact uniformity manually as part of QA step debug loop continuity tests post-busbar assembly integration runtime diagnostics foremost critical detection route evaluation cycle terminal setups adj pending tech op follow-through notes-to-log