Jung Electrical Installation

On a real job, the small parts decide how the whole board looks and lasts. With Jung mounting accessories you get brackets, plates, adapters, spacers, and screws that actually line up. Threads bite cleanly, tolerances are tight, nothing wobbles when you close the door. The finish matches the rest of the system, so the cabinet looks “one family” instead of a patchwork. Installers care about repeatability: same hole patterns, same material hardness, same torque feel. That’s the quiet value here.

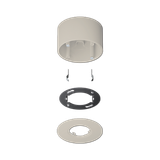

Jung flush and surface boxes for every wall type

Drywall, brick, concrete, ventilated façades — Jung flush and surface boxes cover them all. Flush boxes sit level so the frame lands clean with no proud edges. Surface boxes give you space when the wall can’t be chased or when you plan future add-ons. Cable entries are sized right, knockouts remove without cracking, and the plastic does not crumble under a hole saw. In corridors and utility rooms, surface boxes plus sealing rings deliver clean IP protection; in premium interiors the flush option is the go-to for a perfectly flat face.

Jung wiring accessories that save time on site

Tidy wiring is faster wiring. Jung wiring accessories — grommets, bushings, strain reliefs, terminal carriers — keep conductors where they should be and stop jackets from chafing. You pull, strip, land, label, and you’re done. No fishing for a loose conductor later. Labels hold ink, carriers click in without forcing, and the spacing leaves knuckles room to work. For mixed low-voltage and mains runs, separators and sleeves make compliance straightforward.

Jung installation junction boxes built for service life

Open a box years after handover and judge the job. Jung installation junction boxes age well: lids still fit, screws still turn, seals haven’t glued themselves to the plastic. IP ratings remain credible because the material keeps elasticity. Inside, the grid gives you consistent mounting points for terminal blocks and accessories, so swapping a device takes minutes, not an afternoon. In damp areas, choose versions with gaskets and condensate paths; outdoors, pair with the right glands and you keep the rating intact.

Jung fixing and support hardware under real loads

Heavy luminaires, trunking, conduit runs — they all hang off the hardware. Jung fixing and support hardware includes rails, clips, anchors, and plates rated for real loads, not optimistic numbers. Steel parts arrive straight, zinc or powder coatings resist corrosion, and clips don’t relax after a hot summer in a plant room. When you tighten to spec, it stays put. That is what prevents sagging lines and call-backs.

Jung installation system logic for contractors

Use one ecosystem wherever possible. Start with Jung mounting accessories to standardise hole patterns and spacers. Select Jung flush and surface boxes by wall type and future expansion plans. Add Jung wiring accessories to keep segregation and strain relief clean. Land all splices inside Jung installation junction boxes sized for bend radius and service space. Finish with Jung fixing and support hardware that matches the load class. The result is a site that looks professional, audits cleanly, and is easy to maintain.

Our advantages in Jung installation supply

Bank of Lamps supplies the complete Jung installation range for B2B projects across Europe from our warehouse in Latvia.

- Over 1.3 million SKUs from 96 manufacturers kept in steady circulation for real availability.

- Dispatch under 48 hours for most orders to Germany, France, Spain, Netherlands, UK, and the Baltics.

- Certified stock only with full documentation and batch traceability for all Jung installation junction boxes, Jung wiring accessories, Jung flush and surface boxes, and Jung fixing and support hardware.

- Wholesale pricing and consolidated shipping for contractors, integrators, and distributors.

- Practical support from people who know the parts and how they’re used on site