HENSEL Junction Boxes

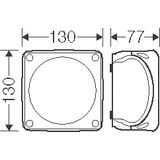

HENSEL Junction box with terminals, 5-pole for_Cu up to 2,5mm2, with removable grom., grey (DP 9221)

Gustav Hensel Installation Boxes & Junction Enclosures — The Backbone of Effective Installations

When you’re specifying how equipment, wiring and terminations are housed — in machine rooms, service cabinets, outdoor panels or infrastructure builds — the quality of the installation box matters. Gustav Hensel installation boxes, junction boxes, flush-mount or surface-mount enclosure boxes provide the structural, environmental and service logic that underpins a reliable installation. In practice you’ll often see Hensel boxes in switch rooms, outdoor feeders, cable routing hubs and industrial installations where robustness, ingress protection and serviceability count.

Understanding the Hensel Installation Box

This category covers a number of product elements:

- Surface-mount installation boxes or junction boxes (large and small) that allow cable entry, terminations and connections in an accessible enclosure.

- Flush-mount boxes (in-wall or panel-mounted) and surface boxes (on-wall fitting) depending on environment.

- Enclosure boxes that may form part of a larger cabinet or distribution board assembly.

- Boxes offering varying levels of protection (IP rating, fire rating, UV resistance, ingress resistance) for indoor, outdoor or harsh environments.

For example, Hensel’s ENYCASE series of junction boxes covers a wide application range: “with a wide range of junction boxes up to protection class IP69, they fulfil the highest requirements for electrical safety, fire protection and UV resistance.”

Key Specification Areas & Real-World Buying Logic

From experience, when procuring installation boxes you’ll want to focus on these practical specs:

- Ingress Protection (IP) & material durability: For outdoor or exposed installations you’ll want boxes rated IP 66/67/69. Hensel’s KF series “weather-proof” boxes are explicitly for outdoor installation with IP 66/67/69.

- Cable entry flexibility: The ability to install glands, knockouts or membranes for cable entry makes a difference in fast installation. Hensel’s boxes provide variable cable entry via elastic membranes, removable membranes or extension rings.

- Mounting and fixing options: Whether wall-mounted, pole-mounted, or fixed to machine frames — Hensel boxes include external brackets, internal fixings, and fast mounting mechanisms.

- Terminal configuration and size: Many junction boxes require terminal blocks, multi-cable connections and space for conductors of various cross-sections. Hensel’s specification sheets mention terminals with 2 clamping points per pole and space for flexible conductors.

- Size, shape and depth: Ensure the box depth and surface area match the cable bundles, terminations and future expansions. For example a typical Hensel box might be 98 × 98 × 58 mm.

In procurement terms: define your environment (indoor dry, outdoor, wash-down, machine-room) → select box series with appropriate IP rating → choose size and mounting style → ensure insertion of terminal blocks and cable gland compatibility → standardise on brand (Hensel) so accessories and spares align.

Stocking and Wholesale Procurement Strategy

For wholesale procurement of installation boxes from Hensel your strategy should cover the following:

- Standardise on one or two box series: For example a general purpose internal box (e.g., DK series) plus a weather-proof external box (KF series) covers most installations.

- Select key sizes: Keep standard small box size (e.g., 100 mm square) and a larger size (200-300 mm square or deeper) for bigger terminations.

- Match pack sizes to site needs: For example boxes of 20 units for indoor works, smaller lots for outdoor special-site work.

- Bundle accessories: Many install boxes require glands, terminal blocks, brackets. Order accessory kits with box if possible to avoid missing parts.

- Maintain spare boxes and lids: Sometimes boxes are damaged, lids cracked or missing. Having spare stock avoids job delays.

- Document part-numbers and traceability: Use the Hensel part-codes and maintain documentation (datasheets, IP rating confirmation) for maintenance and audit trail.

By applying these principles you reduce on-site delays, minimise variant stock, speed up installation and simplify logistics.

Why Gustav Hensel Installation Boxes Are a Smart Choice for Projects

When working across multiple sites, roll-outs or maintenance frameworks, choosing a single trusted brand like Hensel for installation boxes provides consistent quality, predictable spares, known accessories, and installation crews that are familiar with mounting, wiring and servicing. For procurement that means fewer SKUs, predictable stock levels, fewer compatibility issues. For installation teams it means same box types across sites, fewer surprises and easier training. Over the life of a project this consistency helps reduce cost, improve uptime and simplify maintenance.

Wholesale Supply Advantage — Bank of Lamps

Bank of Lamps distributes the full Gustav Hensel installation-box range — installation boxes, junction boxes, flush- and surface-mount enclosure boxes — from our warehouse in Latvia. We serve procurement managers, installers and project roll-out companies across the UK, Germany, Netherlands, Baltic States, France, Spain and Belgium.

Our wholesale advantages include: flexible bulk quantities (from small kits to pallet loads); verified brand-authentic Hensel stock (no grey imports); consolidated EU logistics hub so you avoid customs and multi-shipment complexity; stable wholesale pricing for frameworks and repeat orders; full batch traceability and technical documentation; dedicated B2B support for selection, delivery scheduling and deployment planning. With Bank of Lamps you are not just buying installation boxes — you are securing a supply-chain built for scale, reliability and project success.