Register to unlock your exclusive B2B prices and start shopping. Sign up now!

Distr. board IP65 with term., 1 x 6 mod. (KV 9106)

Order only

Minimal order quantity: 100

Price (excl. VAT):

24,19 €

per pcs

Subtotal: 2 419,00 €

MOQ: 100

EAN: 4012591620921

MPN: 6100057

Package: 1

Pallet: 172

Estimate delivery time at our warehouse (approx.):

2-4 weeks

Technical Information

| Item condition | New |

| Manufacture name | Distr. board IP65 with term., 1 x 6 mod. (KV 9106) |

| Brand | HENSEL |

| Categories |

Small Distribution Boards

|

| Country of origin* | DE |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8536 9095 00 |

| Housing material | Plastic |

| Degree of protection (IP) | IP65 |

| Cover model | Closed |

Packing details

| Packing level 1 | 4012591620921, 4012591620921 |

| Packing level 2 | 4012591620921 |

Other Technical data

| Colour | Grey |

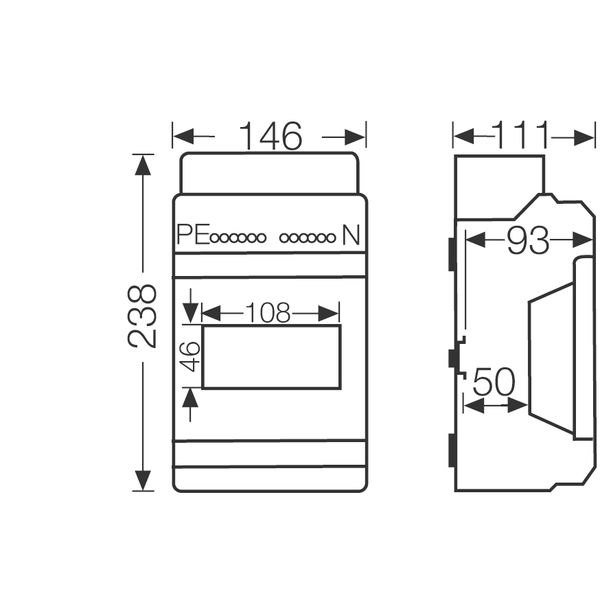

| Width | 146 mm |

| Height | 238 mm |

| Depth | 111 mm |

| RAL-number | 7035 |

| With mounting plate | No |

| Built-in depth | 93 mm |

| Number of rows | 1 |

| Type of cover | Door |

| EMC-version | No |

| Extension possible | Yes |

| Inner depth | 100 mm |

| DIN-rail | Yes |

| Width in number of modular spacings | 6 |

| Transparent cover/door | Yes |

| With lock | No |

Description

This component functions as a pressure regulating valve within hydraulic systems. Its primary task is to control fluid pressure and maintain stability in equipment, preventing damage from overpressure conditions or sudden spikes. It ensures consistent operation by limiting maximum pressures while accommodating variable input flow demands.

### Pressure Regulation Specifications

Operating Pressure: Designed for systems with a max working capacity of up to 250 bar, adaptable to varying ranges based on surrounding system dynamics. Relief settings are pre-calibrated but may require tuning during installation depending on application parameters.

Flow Capacity: Supports steady and controlled regulation for flow rates up to 50 liters per minute under standard operational conditions; performance can vary slightly due to temperature fluctuations or fluid properties.

Material Composition: Constructed from high-strength stainless steel housing resistant to corrosion; internal components include precision-machined brass adjustments and polymer seals rated for industrial-grade durability.

### Installation Requirements

Interface Type: Threaded BSP connections mandatory – compatible threading must be verified prior installation, ideally checked against manufacturer standards. Ensures leak-free interfacing throughout system operation.

Auxiliary Clearances: Requires minimum clearance space around the mounting area due to its physical dimensions (L x W x H ~120 mm x 60 mm x 40 mm). System layouts constricted in design need evaluation before it gets integrated in tight spaces.

Environmental Considerations: Not designed for continuous submersion environments—adequate shielding from excessive moisture or chemical exposure recommended during deployment phases. Operates best within standard humidity/temperature constraints outlined per guidelines (0°C–70°C).

#### Technical Notes / Limitations:

- Tuning required upon commissioning—relief setting variance up ±3%.

- Not suitable for direct use with non-hydraulic fluids (e.g., acids, oils outside specification).

- Temperature tolerance decreases near freezing points—system heating advised for colder climates.

- Seal replacement interval roughly at five years of normal operations depending usage intensity.

Accessories

2,08 €

per pcs

EAN: 4012591111764

MPN: 26001214

Package: 1

2,39 €

per set

Price per pcs: 0,04 €

Qty in SET: 60

EAN: 4012591113768

MPN: 36001011

Package: 60

2,97 €

per set

Price per pcs: 0,05 €

Qty in SET: 60

EAN: 4012591113775

MPN: 36001012

Package: 60

53,57 €

per pcs

EAN: 4012591133049

MPN: 61001154

Package: 1

Pallet: 50

5,04 €

per pcs

EAN: 4012591620297

MPN: 6100029

Package: 1

Pallet: 200

15,93 €

per pcs

EAN: 4012591620440

MPN: 6100044

Package: 1

Pallet: 100

3,73 €

per pcs

EAN: 4012591621874

MPN: 6100170

Package: 1

Pallet: 50

12,45 €

per pcs

EAN: 4012591622529

MPN: 6100252

Package: 1

Pallet: 100

4,98 €

per pcs

Subtotal: 49,80 €

MOQ: 10

EAN: 4012591772217

MPN: 3600132

Package: 1

Box: 10

0,52 €

per pcs

EAN: 4012591772309

MPN: 3600138

Package: 1

Box: 20

Accessories

4012591653318