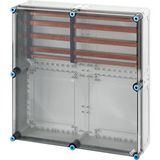

HENSEL Electric box (breaker panel)

cable strain relief 2 cables with max.60 mm, in connection with cable insertion Mi FP 82 (Mi ZE 62)

Gustav Hensel Distribution Boards & Enclosure Systems

When you’re specifying panel systems, distribution boards or electrical cabinets, the enclosure and board architecture set the stage for all wiring, safety, serviceability and future upgrades. Gustav Hensel distribution boards, enclosures and panel systems offer a robust, modular platform built for industrial, commercial and infrastructure installations. In practice you’ll find them in plant-rooms, machine halls, outdoor substations, building distribution zones — anywhere the panel needs to perform reliably under load, in harsh environments or with expansion capability.

Understanding Gustav Hensel Distribution Board Categories

From experience, choosing the right board system means matching your current, future expansion, mounting architecture and environmental rating. Gustav Hensel’s product range includes:

- ENYBOARD (KV Small-type Distribution Boards up to 63 A) — compact boards with modular widths, up to 54 modules, IP54–IP65 protection, thermoplastic enclosures.

- ENYSTAR (Distribution Boards up to 250 A with door) — combinable enclosure system, high ingress protection (IP66), suited for outdoor or harsher installations.

- ENYMOD (Mi Power Distribution Boards up to 630 A) — empty enclosure systems rated for high current installations, modular mounting, compliant with IEC 61439-2.

When selecting, you’ll want to check rated current (63 A → 630 A depending on model), number of modules or ways, enclosure material (thermoplastic vs GRP vs metal), and ingress/impact protection (IP/IK ratings). Also check whether the enclosure supports future extension, busbar systems and standard mounting accessories.

Key Technical Considerations for Procurement

From field experience the parameters that matter most are:

- Rated current and busbar capability – ensure the board supports your feeder current now and allows for future growth. Gustav Hensel lists systems up to 250 A, 630 A.

- Ingress protection and material suitability – for outdoor or industrial use you’ll prefer boards rated IP66 or higher, made from UV-resistant, flame-retardant materials. Gustav Hensel emphasises robust material and IP ratings.

- Modularity and layout flexibility – the enclosure should allow DIN rail, mounting plates, separation of circuits, zones, easy service access. For example, small boards allow 3-54 modules, while larger systems allow full customization.

- Cable entry, wiring space and service access – in practice you’ll see delays when wiring space is insufficient, knock-outs are mismatched, or cable entry is awkward. Board systems from Hensel provide well-designed entries, space, and modular components.

By focusing on these criteria you reduce retrofit risk, minimise wiring congestion, avoid surprises during commissioning and engineer a board system that supports your project lifecycle.

Buying Logic for Wholesale Procurement

As a procurement manager sourcing Gustav Hensel distribution boards for multiple installations or rollout projects, you should apply the following logic:

- Standardise on one or two board families — for example: one “small‐type” family for light commercial use (up to 63 A) and one “power” family for heavy installs (up to 250 A or 630 A). This simplifies stock and training.

- Check material variant based on environment — choose indoor version (lower IP) for office or dry zones, and outdoor/industrial versions (high IP/IK, UV resistant) for machine halls, weather-exposed cabinets.

- Plan accessory and expansion stock — busbars, blanking plates, extension frames, mounting kits. These often need extra stock to avoid site delays.

- Order pack quantities aligned to project phase — e.g., initial rollout boxes of boards, separate boxes of accessories and spares. Avoid one-off SKUs that clutter your warehouse.

- Maintain spare stock of commonly used variants — even good boards need maintenance or changes; keep a few pre-configured enclosures or modules for fast replacement.

- Ensure documentation and compliance — datasheets, certification (IEC 61439 compliance is named by Hensel), traceability. This simplifies audits and client hand-over.

By following that logic you reduce procurement complexity, streamline installation logistics and support long-term maintenance.

Why Gustav Hensel Board Systems Make Sense for Projects

Choosing Gustav Hensel distribution boards means you’re aligning with a brand that offers broad current ranges, strong ingress protection, modular flexibility and proven industrial performance. For procurement this translates into fewer SKUs, familiar hardware across sites, simplified re-orders and consistent performance. For installers you benefit from predictable layouts, familiar enclosure systems, fewer surprises. In large-scale or multi-phase installations this coherence significantly reduces cost overruns, site delays and maintenance burden.

Wholesale Supply Partner: Your Advantages

Our warehouse in Latvia supplies the full Gustav Hensel distribution board and enclosure system range — from small-type boards up to 63 A to power boards up to 630 A — to clients across the UK, Germany, Netherlands, Baltic States, France, Spain and Belgium.

What you gain:

- Flexible bulk quantities tailored to project phases

- Verified brand-authentic Gustav Hensel stock

- Consolidated EU logistics from one hub (reducing customs/shipping complexity)

- Stable pricing for framework or repeat orders

- Full documentation and batch traceability for compliance

- Dedicated B2B support for stock forecasting and delivery planning

With this supply-chain setup you’re not just purchasing boards — you’re securing a supply infrastructure built for scale, reliability and effective rollout.