WAGO Industrial Automation

Basic relay

Starterkit Linux®

Installers choose WAGO when control gear has to be repeatable: terminals that don’t loosen, modules that share one rail geometry, and diagnostics you can reach with a probe—no panel surgery. Below is an assortment-first map you can lift into specs and method statements.

wago automatics and control platform overview for panels and field I O

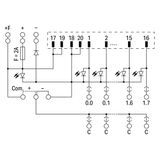

Under wago automatics and control you’ll find a coherent stack: 22/30 mm panel operators, DIN-rail I/O, interface relays, contactors/overloads for small motors, PSUs, and gateways. The rail logic is consistent—marker strips, pluggable jumpers, and test points line up row to row—so wiring rules (conductor class, strip 8–12 mm, torque per device) stay the same whether you’re building AHU starters or compact machine cells. Catalog by function and environment: IP20 board interiors, IP54/65 field boxes, and surge categories that match the room.

wago automation systems architecture, backbones, and segmentation

For small to medium plants, wago automation systems are arranged around modular DIN bases with snap-on digital/analog cards, PSU redundancy options, and clear separation between mains, SELV, and screened signals. Segment I/O where it lives—air-handling, pumps, gates—and bring it back on a deterministic backbone (e.g., fieldbus/ethernet per your standard). Publish node addresses, jumper maps, and spare slot policy in one sheet; that is what keeps expansions tidy and avoids splice farms later.

wago control equipment human interface and panel mechanics

Operators, pilot lights, buzzers, and keyed selectors under wago control equipment share 22/30 mm cutouts with sealed fronts up to IP65, spring or screw terminals 0.5…4 mm², and AC-15 ratings for control duty. Use maintained/twist-release heads for E-stops, momentary NO for start/acknowledge, and colour-consistent lenses with inscription windows. Inside the door, DIN brackets and gland plates are pre-drilled, neutral/earth bars sit on the same offsets, and probe access remains clear after fit-off—so QA photos and meter checks don’t remove covers.

wago industrial automation environments, EMC, and protection classes

Roof fans, pump rooms, and loading bays are hard on electronics; wago industrial automation focuses on survivability: coated PCBs for damp zones, higher surge immunity where long feeders live, stainless hardware in cleaned areas, and screened pairs with 360° braid clamps at gland plates near drives. Keep SELV/mains segregation with divider plates, list max analogue lead lengths, and specify RCD type (AC/A/F) when VFDs or LED drivers share ways—those details prevent ghost trips and noisy analog.

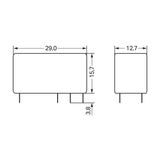

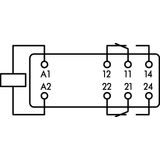

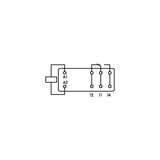

wago relays and contactors interface layers for coils and small motors

Use plug-in interface relays for PLC-to-field isolation (socketed bases, LED status, test lever), and reserve contactors/thermal overloads for motor feeders with coordinated curves. The wago relays and contactors set should state coil voltage (24 V DC common), auxiliary contact maps, and terminal windows that accept ferrules without strand loss. Add arc barriers where panels are shallow, and label mechanical interlocks or HOA selectors on the same line as the device tag so commissioning scripts match the hardware.

wago control modules digital, analog, and power quality I O

Discrete inputs/outputs, 0–10 V/4–20 mA analog, high-speed counters, and even power-quality sampling land on slim DIN slices; wago control modules expose status LEDs and probe points that face the door, not the backplate. Trend PF/THD where lighting or small drives behave oddly, and always record channel scaling, filter times, and sensor power (two-wire vs four-wire) in the panel schedule to avoid midnight rework.

wago automation devices gateways, PSUs, and system services

Gateway bricks bridge KNX/DALI/Modbus to your chosen controller; PSUs feed 24 V DC rails with brownout ride-through and clear inrush data; managed switches keep diagnostics reachable. Package these as wago automation devices with spare DIN pitch, labelled test pins, and documented earth bonding. When you swap a module, the label, jumper, and probe positions don’t change—exactly what maintenance wants.

Technical specifications and standards that matter

Supply 230/400 V AC mains; 24 V DC control rails. Terminals typically 0.5…4 mm²; strip 8–12 mm; torque per device label. Control components per IEC/EN 60947-5-1; E-stops per 60947-5-5/ISO 13850; enclosures to EN 62208/IEC 60529 (IP). Drives/starters under IEC 60947/IEC 61800-5-1; EMC to EN 61000 family. Keep SELV/mains segregation, 360° screen bonds at gland plates, and publish max lead lengths for analog and PWM to protect accuracy and insulation.

Applications and compatibility

• AHUs and plant rooms: start/stop stacks, HOA selectors, DP/pressure loops, fire-mode interlocks.

• Pumps and boosters: dual-PID pressure/level, dry-run detection by PF/flow, soft-fill ramps, check-valve interlocks.

• Gates and shutters: monitored edges, photocells, torque limits, encoder inputs with force-test records.

All assemblies align with common DIN hardware and field boxes—same rail pitch, label format, and probe access.

Selection checklist for B2B buyers

- Fix motor kW and duty → choose DOL/soft start/VFD, coil voltage, and RCD type.

- Define I/O map: discrete vs analog counts, scaling, sensor power, and spare slots.

- Lock enclosure IP/IK, door cutouts, gland threads, and surge category; route shields 360°.

- Publish wiring practice: conductor class, strip/torque windows, SELV barriers, and test points.

- Reserve gateway/PSU redundancy and marker scheme; barcode modules to the panel schedule for clean maintenance.

Advantages of working with Bankoflamps

Trade customers work with individual B2B pricing, custom offers, and a dedicated account manager. Quotes return fast—around an hour—and ordering by EAN/MPN is straightforward. The client portal shows live stock across EU warehouses, current lead times, order status, and provides downloadable price lists that remain up to date. Purchase history and analytics are available for planning. Trusted clients can use post-payment terms up to 30 days. We consolidate shipments to reduce delivery costs, keep prices valid for defined periods, and support customers in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.