TURCK

Turck sensors and automation for reliable, data-driven plants

Turck is known for robust field instrumentation, modular I O, and connectivity that survives real factory conditions. Below is a buyer-centric map: how to choose sensing technologies, wire them cleanly, and document performance so maintenance and production both win.

Turck in the control stack what to standardize

When you scope panel and field hardware together, start with the brand’s core portfolio in Turck industrial automation to align I O modules, connectors, junction boxes, and cordsets with your PLC and network standards. Unifying families reduces commissioning time and spares.

Turck sensors selection framework by application risk

For conveyors, presses, fillers, and packaging cells, shortlist sensing families and housings through Turck industrial sensors. Decide per zone:

- Environment IP and chemical exposure, washdown, weld spatter, outdoor UV

- Mounting thread sizes, flush vs non-flush, clearances, vibration class

- Electrical interface PNP NPN, IO Link, analog, or bus couplers

- Diagnostics needed switching counts, quality factor, contamination alarms

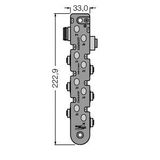

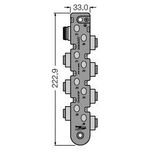

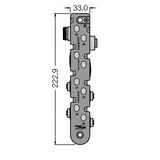

Turck proximity detection for metal, plastics, and hygiene zones

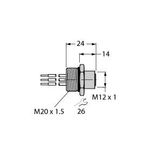

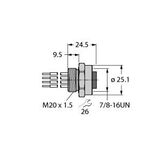

Inductive for metal targets, capacitive for level and non-metal, magnetic for harsh actuations. Build your BOM by thread and sensing face using proximity sensors, then set:

- Switching distance with safety factor for temperature drift and tolerances

- Flush vs non-flush installation to avoid side-triggering

- Short-circuit and reverse-polarity protection on shared supplies

- LED state, test buttons, or IO Link events to speed troubleshooting

Turck pressure monitoring for pumps, pneumatics, and utilities

Stabilize utilities and catch faults early with pressure sensors sized to the medium and duty cycle:

- Range and overpressure rating, burst pressure, and proof pressure

- Wetted materials stainless grade, seal compatibility with oils, CIP, or coolant

- Output type analog 4–20 mA or 0–10 V, switching outputs, IO Link for parameter sets

- Zero span adjustment, damping, and temperature compensation for stable reads

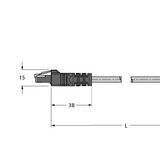

Wiring, networking, and EMC hygiene with Turck

- Use star-point grounding for shielded runs; segregate sensor supply from VFD cabling

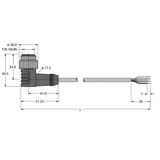

- Prefer molded M12 cordsets with the right keying; document color-code and pinout

- For IO Link, standardize parameter blocks and device IDs; back up configs in the job pack

- In weld or HF fields, verify EMC immunity and add ferrites or metal-backed brackets as needed

Commissioning and QA checklist

- Prove-out: simulate targets, record actuation distances, log hysteresis and repeatability

- Analog scaling: validate raw counts to engineering units at two points plus zero

- Alarms: set debounce and filter times to avoid chatter; document thresholds

- Traceability: attach sensor IDs, cable lengths, and calibration notes to the line’s maintenance record

Maintenance playbook for uptime

- Quarterly: clean sensing faces, verify LED and diagnostics, check mechanical clearances

- Semiannual: inspect cordset strain reliefs and M12 torque; confirm IP integrity of glands

- Event-driven: after crashes or jams, re-verify proximity alignment and pressure setpoints

Why source Turck from Bank of Lamps

Bank of Lamps is a wholesale distributor with real-time stock, EU-wide delivery from a Latvia warehouse, bulk pricing, and consolidated multi-brand shipments. We help engineering and procurement align device families, documentation packs, and replenishment cycles for stable operations.