THORGEON Lamp holders

thorgeon lamp holders for professional luminaires

Ceramic and reinforced PA options cover G13 T8, G5 T5, GU5.3 MR16, GU10, GX53, and G53 AR111 with heat paths sized for drivers or transformers nearby. Contacts use tin or nickel plating; creepage and clearance follow IEC 60061 geometry. Clip forces are tuned so tubes don’t walk under vibration. Installers specify thorgeon lamp holders where captive screws, keyed inserts, and repeatable clamp torque keep service fast; stocked thorgeon lamp holders are indexed by cap type, temperature class, and wiring style.

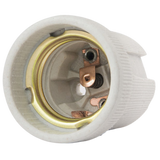

thorgeon bulb sockets temperature and wiring data

E27 and E14 bodies pair ceramic cups at hot points with polymer collars to save mass in gypsum ceilings. Terminals accept 0.5…2.5 mm² copper, strip 8–12 mm; typical tightening 0.5–0.8 Nm. Glow-wire ratings land at 650–850 °C on hot zones; retention springs resist shock in lift lobbies. Crews choose thorgeon bulb sockets when retrofit LEDs and halogen histories mix, and they group thorgeon bulb sockets by collar depth and thread so bezels sit flush.

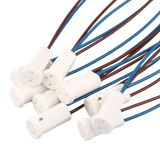

thorgeon lighting connectors in gear trays and canopies

Push-in and screw-cage blocks handle 0.34…1.5 mm² for control and 1.0…2.5 mm² for mains, with keyed low-voltage positions to prevent cross-mating DALI or 0–10 V. Test ports take 2 mm probes; markers remain legible after solvent wipe-downs. With thorgeon lighting connectors, EMC is preserved via 360° braid clamps at entry plates; the same thorgeon lighting connectors appear across trays, bulkheads, and pendant kits so harnesses don’t change.

thorgeon lamp bases mechanical fit and retention

GU10 twist-locks use bayonet cams with anti-rotation plates; GU5.3/GX5.3 pins land in sprung sleeves for low contact resistance; G53 screw terminals take 1.0…2.5 mm² with 0.6–1.0 Nm torque. Spacer rings correct uneven plaster and maintain bezel plane. Spec sheets for thorgeon lamp bases list pin materials, contact force, and allowable axial load so aiming doesn’t drift; maintenance logs tie thorgeon lamp bases to beam class and trim depth.

thorgeon mounting holders geometry for repeatable installs

Crossbars and carrier plates share 60 mm and 84 mm hole families, skyline-low profiles, and ±10 mm slotting for fine centring. IK notes and load factors are printed or etched; stainless A2/A4 variants suit ammonia or coastal air. Designers rely on thorgeon mounting holders to keep cut-out offsets identical across floors; procurement tags thorgeon mounting holders by pitch, substrate kit, and allowable load for unambiguous goods-in checks.

thorgeon electrical fittings ingress and earthing practice

Glands M16/M20/M25 with matched ferrules hold IP54–IP65; drain/breather plugs mitigate pressure cycling in sealed lids. Earth tails remain short and direct; serrated locknuts prevent walk on thin doors. When specified as thorgeon electrical fittings, assemblies ship with torque notes and pull-out ≥60 N for strain relief; using thorgeon electrical fittings across families keeps acceptance testing the same from corridor cans to façade bulkheads.

thorgeon socket accessories service parts and kitting

Collars, bezels, label frames, gasket sets, and anti-tamper caps arrive room-bundled with clear EAN/MPN. Heat shields protect trims near halogen or tight LED drivers; colour collars segregate SELV and mains. Estates stock thorgeon socket accessories by finish, collar depth, and thread to avoid ad-hoc fixes; field teams confirm thorgeon socket accessories by tray QR so spares match drawings.

Technical specifics engineers actually use

- Conductor windows: 0.34…1.5 mm² for control, 0.5…2.5 mm² for mains; ferrules per EN practice on fine-strand.

- Torque ranges: 0.5–0.8 Nm small clamps, up to 1.0 Nm on G53 screws; verify per data sheet.

- Thermal: respect Tc near enclosed heads; ceramic at hot points, polymer elsewhere to cut weight.

- IP/IK: IP20 in voids, IP54/IP65 with gaskets; IK08–IK10 hardware for public zones.

- EMC: 360° shield termination at entry plates; keep divider strips between SELV and mains.

Applications and compatibility

Apartments and hotels use shallow collars and locator labels; offices rely on keyed GU10/GU5.3 for quick swaps; plant rooms require stainless clips and gasketed entries; car parks need vandal-resistant trims. Parts align with common DIN rails and Euro-channels; thread families remain metric so the same tools and ferrules fit across panels and luminaires.

Selection criteria for B2B buyers

Fix cap/base and temperature class first; lock collar depth against trim and plaster thickness; choose thread and gland by environment; confirm strip window and torque in the worksheet; pilot a room to validate IP, glow-wire points, and aiming retention before bulk release.

Advantages of working with Bankoflamps

We ship in the order crews install. Quotes with EAN/MPN land in about an hour, and live EU stock is visible before teams are booked. Your portal shows lead times, shipment tracking, and downloadable price lists with validity windows you can plan around. Trusted accounts use post-payment up to 30 days. We consolidate per room bundle so holders, collars, gaskets, glands, and trims arrive together, and your account manager checks cap types, torque windows, conductor ranges, thread families, and bezel geometry against your drawings to keep kits site-ready across France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.