Telemecanique Control devices, buttons

Telemecanique Emergency stop rope pull switches XY2C, cable end protector, Ø 3.2 mm, for XY2C

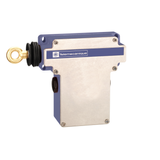

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, e XY2CE, RH side -2NC+2 NO, Booted pushbutton

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, cable 300 V AC, 10amp, XY2CE

TRIP WIRE SWITCH

Simple rope pull switch, Telemecanique Emergency stop rope pull switches XY2C, 1NC + 1 NO, snap action, 240 VAC, 10 A, XY2CD

PILOT LIGHT HEAD ORANGE

TRIP WIRE SWITCH

TRIP WIRE SWITCH

TRIP WIRE SWITCH

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, simple reset by flush push button

TRIP WIRE SWITCH

TREKKOORDSCH.NOODSTOP R.ZIJDE 2NC PG13

DUAL EM. RP. SW. FL. RESET BUT. NO LIGHT

ATEX D.EM.RP.SW. KEY RESET BUT. NO LIGHT

DUAL EM.RP.SW. KEY RESET BUT. YEL.LIGHT

DUAL EM.RP.SW. KEY RESET BUT. NO LIGHT

DUAL EM.RP.SW. SIL. FL.RES.BUT. NO LIGHT

XY2CED PULLEYS (BAG10ST)

NIPPLE PG11 - CM16

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, e XY2CJ, straight, 1NC+1 NO, Pg13.5

***XY2CED END SPRING

XY2CED PULLEY SUPPORTS (BAG10ST)

BELLOWS

Telemecanique Emergency stop rope pull switches XY2C, mounting kit, Ø 3.2 mm, L 10.5 m

HEAD FOR MANUAL SWITCH

E.STOP TRIP WIRE 1 NC.NC CONTACT , RESET

TREKKOORDSCH.NOODST.L.ZIJDE 1NC+1NO PG13

TREKKOORDSCH.NOODSTOP R.ZIJDE 2NC M20

TREKKOORDSCH.NOODSTOP RECHT 1NC+1NO M20

Pilot light, Telemecanique Emergency stop rope pull switches XY2C, orange XY2C, incandescent, clear, screw base, 24 V

CABLE

Telemecanique Emergency stop rope pull switches XY2C, red galvanised cable, Ø 5 mm, L 50.5 m, for XY2C

TRIP WIRE SWITCH

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, RH side, 2NC+2 NO, pilot light 230 V

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, RH side, 2NC+2 NO, pilot light 130 V, boot

***TRIP WIRE SWITCH

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, e XY2CE, LH side -1NC+1 NO, Flush pushbutton

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, e XY2CE, LH side -2NC+2 NO, Booted pushbutton

TRIP WIRE SWITCH

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, LH side, 2NC+2NO, pilot light 130 V

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, simple reset by flush push button

TRIP WIRE SWITCH

Simple emergency stop rope pull switch, Telemecanique rope pull switches XY2C, e XY2CE, LH side, 1NC+1 NO

Latching emergency stop rope pull switch, Telemecanique rope pull switches XY2C, simple reset by flush push button

***DUAL EMERGENCY STOP RO PULL SWITCH

Dual emergency stop rope pull switch, Telemecanique rope pull switches XY2C, e 2x(1NC+1NO), Pg13.5, boot. pb

EMERGENCY STOP TRIP WIRE SWITCH WITHOUT

EMERGENCY STOP TRIP WIRE SWITCH WITH SIG

TRIP WIRE SWITCH

telemecanique control devices for reliable operator fronts

Front elements and contact blocks share a 22 mm cut-out with anti-rotation keys, keeping door machining simple and repeatable. Bezels are metal or reinforced polymer with IP65 to IP69K when paired with the correct gasket set. Contact ratings cover AC-15 230 V at 3 A and DC-13 24 V at 2 A in typical stacks. Crews standardise on telemecanique control devices so depth behind the door, clamp style, and marker sizes stay uniform across cabinets; the same telemecanique control devices also simplify spare holding during phased handovers.

telemecanique push button switches configurations and ratings

Momentary and maintained actuators come in flush, extended, mushroom, and illuminated versions. LED modules are 12 V, 24 V DC, and 110 or 230 V AC with pluggable light blocks; colour fidelity holds after solvent wipe-downs. Clamp options include screw cages and push-in springs for 0.5…2.5 mm² with typical torques 0.5–0.8 Nm. For night-shift diagnostics, lens windows remain readable at oblique angles. Installers specify telemecanique push button switches where tactile feedback and repeatable actuation force matter, and they pair those telemecanique push button switches with keyed contact blocks to prevent mis-stacking.

telemecanique selector switches options for mode control

Two-, three-, and four-position variants are available with stay-put or spring-return logic; keys, padlock hasps, or removable handles enforce access level. Clear position detents survive vibration on compressor skids and lift motor rooms. Typical front sealing is IP66 with rear IP20 on the contact block; use rear shrouds where finger-safe is required. Engineering teams adopt telemecanique selector switches to segregate Auto Hand Off and maintenance states, and they mark those telemecanique selector switches with consistent legend plates across floors.

telemecanique emergency stop buttons safety practice

Mushroom heads 30–40 mm or 60 mm support twist-to-release or key-release, with positive-opening NC contacts and optional redundant circuits. Collars are yellow with red heads per plant standards, and guard rings help against accidental operation in tight corridors. Latching mechanisms are rated for high cycle counts; contact blocks carry forced-guided geometry for downstream safety relays. In conveyor and façade zones, planners place telemecanique emergency stop buttons at reach points every 6–10 m and record reset style in the drawings so technicians service identical telemecanique emergency stop buttons without re-training.

telemecanique control panels layout and integration

Door hardware, legend carriers, and cable glands share a consistent dimensional language, so front layouts clone easily between rooms. DIN rows are spaced 7.5–10 mm for airflow; wiring ducts keep 45 mm cover height for bend radius. A single marker and colour system covers operators, relays, and terminal strips to cut reading errors. Designers reference telemecanique control panels when they need predictable pitch and torque tables; maintenance crews prefer telemecanique control panels because identical touch points reduce fault-finding time.

telemecanique operator interface devices in harsh and clean zones

Compact HMIs and pilot stations use bright, high-contrast lenses and IP65 faces for washdown or dusty bays; anti-condensation gaskets protect contact blocks. Enclosures offer shallow depth for door mounting above dense rails. For glove use, large actuators and raised guards maintain accuracy. Integrators choose telemecanique operator interface devices so panel doors mix HMIs, lamps, and actuators without clearance clashes; procurement tags those telemecanique operator interface devices by cut-out count and illumination voltage to stabilise BoMs.

telemecanique control accessories mounting and wiring detail

Rear adapters, contact block extenders, booted pushers, and LED light blocks share the same bayonet and screw interfaces. Anti-rotation plates stop creep on thin stainless doors; sealing kits include closed-cell gaskets that recover after service. Contact blocks stack up to three deep while keeping IP on the front; test tabs and LED status speed commissioning. Stock telemecanique control accessories by legend size, block type, and clamp style; crews then build identical stacks of telemecanique control accessories across panel families without ad-hoc parts.

Advantages of working with Bankoflamps

Our support tracks commissioning windows. Quotes with EAN and MPN land in roughly an hour, and real-time EU stock is visible before crews are booked. The portal shows lead times, shipment status, and downloadable price files with validity periods you can plan around. Trusted accounts can use post-payment up to 30 days. We consolidate partials so each door kit, contact stack, and gasket set arrives room-bundled, and your account manager checks cut-out templates, block combinations, illumination voltages, clamp styles, and torque notes against your drawings—keeping panels site-ready across France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.