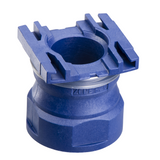

Telemecanique Cable inlet

telemecanique cable inlet options for panels and luminaires

Specify straight and right-angle bodies with metric threads M16 M20 M25 M32 and locknuts for 0.5…2.5 mm² copper. Body materials include reinforced PA for indoor grids and nickel-plated brass for façades and rooftops. Typical service window is −25…+105 °C with UV-stable blends where skylights and atria introduce sunlight. With telemecanique cable inlet parts, installers keep bezel planes and bend radii consistent, so gear-tray swaps don’t disturb gasket compression around the entry.

telemecanique cable glands sizes and IP performance

Ring-nut or dome-nut versions cover cable OD 3…6.5 mm 6…12 mm 10…14 mm and 13…18 mm; sealing inserts are EPDM or silicone. Correct ferrule and jacket pairing keeps IP65–IP68 after repeated servicing. For vibration zones, captive anti-twist inserts prevent sheath spiral under torque. Crews stock telemecanique cable glands by thread family and OD range to avoid on-site rework that would compromise ratings.

telemecanique cable entry systems modularity for multi-cable routes

Frame-and-insert kits let you pass mixed diameters through the same cut-out while preserving EMC and IP. Split inserts accept pre-terminated connectors, useful in retrofit ceilings and elevator machine rooms. Breathable membranes or drain/breather plugs handle condensation without losing the seal. Using telemecanique cable entry systems, planners keep identical hole geometry across floors and only vary inserts to match the room bundle.

telemecanique sealing cable entries materials and torque windows

Closed-cell EPDM suits indoor voids; silicone carries higher temperature and better recovery after maintenance. Typical tightening ranges sit around 2.0–3.0 Nm for M16, 3.0–4.5 Nm for M20, and 4.5–6.0 Nm for M25, always verified against the data sheet and jacket hardness. For coastal or ammonia-rich air, stainless or nickel-plated bodies stop thread oxidation that would raise contact resistance on earthing tags. With telemecanique sealing cable entries, QA teams can record torque and pull-out values at goods-in and repeat them during handover.

telemecanique electrical cable access EMC practice and segregation

Shielded leads terminate on 360° braid clamps at the entry plate to avoid pigtail inductance; PE tails stay short and direct to the backplate. Keep SELV and mains lanes separated with divider strips and colour collars. Where VFDs sit nearby, use metal-body entries bonded to the enclosure for reference. Standardising telemecanique electrical cable access across cabinets means coil noise and LED-driver harmonics do not bleed into sensor lines.

telemecanique wiring inlets for control and power harnesses

Push-in strain reliefs protect fine strands on 0.34…0.75 mm² signal leads; screw-cage variants clamp 1.0…6.0 mm² for power. Low-profile cups fit shallow bulkheads and keep label windows visible. In luminaires, ceramic stand-offs shift heat away from polymer entries near drivers. Maintenance crews catalog telemecanique wiring inlets by pole count, strip window, and conductor class so night shifts aren’t improvising ferrules.

telemecanique cable protection fittings strain relief and mechanical data

Right-angle adaptors, locknuts with serrations, and sealing washers preserve IP on thin doors and composite panels. Anti-vibration couplers prevent gland walk during thermal cycling; pull-out ≥60 N is typical when sized to jacket OD. Metallic conduit adaptors maintain continuity for low loop impedance in automation bays. Specifiers choose telemecanique cable protection fittings when trunking must bridge mixed substrates without changing thread families.

Applications and integration across Telemechanique ecosystems

Apartments and hotels lean on shallow cups, retained screws, and colour collars for tidy roses; offices use modular frames to speed churn; plant rooms demand gasketed entries and brass bodies; car parks and façades need IP66/IP68 and anti-tamper caps. Entries, glands, and frames align with Telemechanique terminals, relays, and drives—same pitch logic, same M16/M20/M25 openings—so crews keep one tool and ferrule set through the build.

Selection criteria for B2B buyers

Fix cable OD and conductor class first, then lock thread and material by environment. Map EMC need—braid clamp vs plastic body—before choosing the frame. Verify gasket type and target IP; record torque windows and pull-out in the test sheet. For prefabrication, keep one cut-out and vary inserts; for maintenance, standardise labels and colour collars so routes are obvious at a glance.

Advantages of working with Bankoflamps

Our logistics follow installation order, not catalogue order. We price to room schedules and display live EU stock before crews are booked. Quotations with EAN and MPN arrive in roughly an hour; the portal shows lead times, shipment tracking, and downloadable price files with validity periods you can plan against. Trusted partners use post-payment up to 30 days. We consolidate partials so cartons land per room bundle, and your account manager checks thread size, OD range, insert set, braid-clamp requirement, and torque notes against drawings—keeping entries and telemecanique cable glands consistent from risers to façades across France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.