STAR TRADING Lighting accessories

star trading lighting accessories range overview

This category is the small hardware that decides whether a lighting job installs quickly and survives service. Expect lampholders and caps, inline/panel connectors, ceiling roses, cord sets, brackets and crossbars, grommets and glands, plus service pieces—diffusers, latches, gaskets, and collars. Indoor parts are typically IP20; outdoor items step to IP44/IP65 with silicone seals and UV-stable plastics. Plastics are PC/ABS blends with glow-wire 650–850 °C; metalwork is zinc-plated or stainless where impact or weather is a factor. Pull-out on cord grips lands ≥60 N when the jacket OD matches the insert. Threading and hole geometry are shared across sizes so crews don’t drill new patterns mid-fit.

star trading lamp holders formats and thermal classes

E14/E27 screw collars, GU10 cups, G13/G5 tombstones, and shallow GX53/G53/GU5.3 seats cover most fixtures. Use thermoplastic bodies (T180) for open shades and ceramic (T210–T300) when the crown runs hot—compact downlights, glass chimneys, or enclosed pendants. Contacts are nickel-plated brass or phosphor bronze; terminations accept 0.5…2.5 mm² with screw-clamp or push-in cages. Fire-hood friendly GU10 cups ship with spring retainers and rear bosses for strain relief. Tombstones are available in locking variants for T-LED conversions so tubes don’t twist during maintenance.

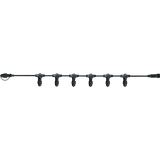

star trading lighting connectors and low-voltage links

You’ll find 2–5-pole inline plugs, panel sockets, and quick clips for through-wiring. Tool-less spring cages speed bench builds with ferruled fine-strand; screw terminals win where solid and stranded mix. Rated 250/450 V depending on series; many parts are keyed to block polarity mistakes. For SELV runs, choose 2- or 3-pole low-profile plugs; EMC-aware builds add 360° braid clamps at entry plates so shielding continuity reaches the metal housing. IP ratings depend on insert + back-shell: IP20 in ceilings, IP65 with compression glands outdoors. Match ferrule to jacket OD or the seal will not hold.

Hardware sets under star trading mounting kits

Brackets, crossbars (Ø68/Ø75/Ø83/Ø100/Ø120 mm patterns), spring carriers, trimless frames, and gear-tray plates share hole maps across families. Ceiling roses include captive strain-relief and cord-grip inserts; offset plates fix canopy clashes at beams and conduits. Channel clips and trunking adapters keep surface runs straight; printed load/torque windows on the steel save guesswork. For open ceilings and workshops, galvanised hardware rides out knocks; add soft inserts where vibration or finished timber needs protection.

Service drawer and star trading lighting spare parts

Real jobs need replacements: clear/opal diffusers, gasket sets, lock-rings, springs, bails, lamp-side collars, and screw packs with the correct head/finish. Keep 2–3 % overage on diffusers—these scratch late in a program. Shade couplings are threaded metal rather than plastic in the service line, so repeated relamps don’t chew threads. If luminaires present IP fronts, order the exact gasket profile; “close enough” drops an IP44 face to IP20 after the first clean.

Integration with controls, wiring, and boxes

Lampholders and connectors land inside standard boxes and plates; creepage/clearance is preserved by insulating backers on metal trims. Where phase-cut dimming is used, pick quiet trailing-edge channels for LED loads and keep plate loads within the dimmer’s stable window to avoid shimmer. SELV control pairs should run in separate conduit from mains; label polarity at every low-voltage connector so swaps don’t break scenes months later. This is where star trading installation accessories—labels, QR sleeves, junction tabs, reducers and step rings—earn their keep.

Applications and fit notes installers actually use

- Apartments/hotels: neat ceiling roses with keyed cord grips, GU10 cups that tolerate insulation touch, and mini G45/E14 collars that hide cut edges.

- Retail: vandal-resistant canopies, locking G13/G5 tombstones above counters, inline connectors for fast churn.

- Plant/utility and façades: gasketed junctions, stainless fixings, UV-stable plastics, and IP65 connector backshells; add drain/vent plugs on large outdoor boxes.

Standards and numbers that matter

Assemblies follow EN/IEC 60598-1 (plus -2-4 for portable); caps/bases per IEC 60061; LED modules EN 62031 with drivers to EN/IEC 61347-2-13 and IEC 62384. EMC sits under EN 55015/EN 61547; mains quality EN 61000-3-2/-3-3. Glands and strain relief reference EN 62444—size the insert to jacket OD and publish torque on the drawing. Photobiological safety for lamp/engine swaps is RG0/RG1 per EN 62471 on typical outputs.

Quick selection logic for planners

- Cap/base + T-class (E/GU/GX; T180 vs T300).

- Termination (screw vs spring-cage) and conductor mix.

- IP need (IP20 ceilings, IP44 bathrooms, IP65 façades)

- Mounting geometry (cut-out and crossbar pattern).

- Cable path (gland thread, ferrule size, exit direction).

- Service pack (gaskets, diffusers, collars) with 2–3 % overage.

Procurement lines that avoid re-picks

Write each node as: series + cap/connector + IP + thread/OD + fixing set + finish.

Example: “Rose Ø100, E27 ceramic T300, strain-relief M16 6–10 mm, crossbar Ø83, white, gasket kit.”

If BOMs bundle lampholders, brackets, glands and leads, tag that as star trading lighting components in your sheet so cartons land kitted.

Bankoflamps B2B

Individual pricing aligned to room schedules; your manager cross-checks caps, T-classes, IP, gland sizes, hole patterns and accessory codes against drawings. Live EU stock by warehouse; quotes in about an hour with EAN/MPN, torque windows, and kit suggestions. Orders go by manufacturer code; dated price lists, lead-time tracking, and consolidated shipments by zone reduce site handling across France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands. Post-payment up to 30 days is available for approved accounts.