Spectrum Luminaire accessories

spectrum luminaire accessories ranges and materials

This catalog groups the mechanical and electrical small parts that make fixtures install cleanly and survive servicing. Housings and canopies come in PC/ABS, glass-fiber reinforced PA, and die-formed steel; indoor pieces are typically IP20, while gasketed lids, compression glands, and UV-stable compounds lift exposed parts to IP44–IP65. Impact classes sit around IK06–IK08 for public areas. Plastics follow glow-wire 650/750/850 °C (IEC 60695-2-11/12) where ceiling voids and corridors demand it. Threads, hole geometry, and pitch are kept consistent across sizes so mixed rails and covers line up without slotting on site.

spectrum mounting kits for ceilings, tracks, and channels

Ceiling roses, drop-cord sets, crossbars, gear-tray brackets, and trunking clips arrive as matched sets with fixings, cord grips, and strain relief. Brackets are zinc-plated or galvanized steel in 1.0–2.0 mm gauges; permissible loads and safety factors are printed/etched on the steel. Track adapters cover single/three-circuit footprints with mechanical keys that prevent mis-insertion. For open ceilings and workshops, channel clips include vibration pads to stop buzz on thin-canopy pendants. Spacer rings correct uneven plaster so trims sit flush; slotted bars respect common downlight diameters to keep cut-outs standard across rooms.

spectrum lamp holders footprints and ratings

Caps and bases follow IEC 60061: E27/E14 screw, GU10/GZ10, G13/G5 for linear, GX53/G53 for shallow fittings, and GU5.3 where depth exists. Thermoplastic bodies handle general duty; ceramic variants ride higher temperatures near enclosed shades. Typical thermal classes: T180 for polymer cups, T210–T300 for ceramic. Contacts use nickel-plated brass or phosphor bronze. Screw and push-in cages accept 0.5…2.5 mm² Cu; fine-strand behaves best when ferruled (DIN 46228). Lead insulation is usually 90–110 °C; check the canopy’s airflow before approving 60 W+ lamps in compact shades.

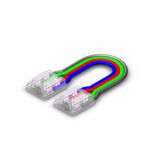

spectrum lighting connectors and field wiring

Inline and panel connectors arrive in 2–7 poles with keyed housings to prevent phase/neutral swaps. Options: screw-clamp for mixed solid/stranded, cage-clamp for speed, and push-in for ferruled fine-strand. Rated 220–240 V, 2–16 A depending on frame; some polarized low-voltage formats carry SELV runs to drivers. IP ratings depend on ferrule choice and gland sizing (EN 62444); pull-out loads ≥60 N are typical for pendant sets. Numbered cores and printed metre marks shorten FAT/SAT and reduce re-termination during churn.

Optical, sealing, and mechanical components

Diffusers (opal, micro-prismatic, ribbed), lenses, and reflectors are cut to common tray geometries; micro-prismatic PC keeps UGR low in offices while opal PMMA softens point sources in hospitality. Gasket kits use EPDM or silicone with compression stops so lids hold IP after multiple services. Latches, bails, and hinge pins are stainless where coastal or wash-down areas are specified. End-caps and corner inserts for linear bodies suppress light leaks at mitres; choose matte or bright inner liners to keep CCT uniform in decorative shades.

Control and protection items that finish the build

Terminal blocks with PE jumpers, thermal fuses, and cord-grip bushes keep assemblies safe under EN/IEC 60598-1. For EMC-sensitive rooms, 360° braid clamps at entry plates provide a low-impedance bond for shielded leads. Inline switches and foot pedals are rated for 2–4 A with snap action contacts; specify creepage/clearance matching overvoltage category II/III per location. Where dimming is planned, keep polarity-safe low-voltage plugs on driver leads so maintenance cannot cross DMX/DALI/0–10 V with mains.

spectrum spare parts for luminaires service sets

The service drawer mirrors wear items: clear/opal lids, lenses, gaskets, cord grips, latches, lampholder inserts, and decorative collars. Hold 2–3 % overage for diffusers—these are scratched most during late works. Label sleeves and frame tags keep identification consistent floor-to-floor, which cuts time during defect walks and churn.

Standards and sizing that actually drive selection

- Interfaces and safety: IEC/EN 60598-1 assembly rules; caps/bases per IEC 60061; tungsten/halogen holders to IEC 60432-2.

- Plastics and heat: glow-wire to 650/750/850 °C per room class; holder T-class matched to lamp/driver heat

- Cabling/glands: EN 62444 sizing; match ferrule to jacket OD to preserve IP.

- Containment: trunking to EN 50085 with divider strips where power/control share routes.

- Marking: torque windows printed on kit cards; maximum envelope temperature noted at the canopy for enclosed shades.

Kitting logic and families at a glance

Think in functional families rather than one-off parts: ceiling roses with matched cord sets; crossbars plus retainers for downlights; linear end-caps and joiners for channels; keyed low-voltage plugs with driver tails; gasket/latch packs for sealed bodies. Where the spec describes the package as spectrum lighting accessories, align finish (white/black/aluminium/bronze) across ceiling, wall, and pendant pieces so a room reads as one system. When drawings list room bundles under spectrum installation accessories, group canopies, holders, glands, labels, and gasket sets by area to keep cartons site-ready.