Socomec Switch Disconnectors

socomec switch disconnectors scope and brand context

On real boards—UPS bays, changeover panels, MCC rooms—the isolating function must be unambiguous and the handle action predictable. Socomec focuses on positive isolation, repeatable making/breaking at rated load, and padlockable control so maintenance can lock out safely during FAT/SAT and service. Typical Ui is 690 V AC with Uimp 6–8 kV; current frames run from 16 A to 1600 A in open devices or enclosed units for wall mounting. Operating temperature commonly spans −25…+55 °C with altitude derating above 2000 m. Door-coupling keeps the shaft and handle rigid so the OFF position actually opens the knife on the base—visible isolation on larger frames reassures inspectors and plant engineers.

socomec load break switches product range and series overview

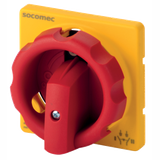

You’ll see plate-mounted bases for panel doors, DIN-rail bodies up to the small frames, and IP65 enclosed versions with red/yellow E-stop style handles for plant floors. Pole sets include 3P, 3P+N, and 4P; add-on neutral and early-make/late-break auxiliaries support TN-S and measurement chains. Utilization categories are stamped on the label—AC-22A for mixed resistive/inductive loads and AC-23A where motor feeders and transformers demand higher breaking duty. Accessories cover shaft lengths, door interlocks with defeater keys, up to three padlocks in OFF, auxiliary contacts (OF/SD) for status, terminal shrouds, and bridging bars for rear or front cabling. DC variants exist for battery strings and PV combiner duties; multi-pole series connection achieves DC-21B/DC-22B ratings when specified.

socomec rotary disconnectors technical specifications and standards

Conformity anchors to IEC/EN 60947-3 for switches, disconnectors, switch-disconnectors and fuse-combination units. Thermal current Ith is published per frame; short-time withstand Icw (1 s) is typically 10–50 kA depending on size, with conditional short-circuit ratings when backed up by gG or aM fuses to the vendor’s table. Making/breaking categories: AC-22A, AC-23A, and for fuse-switch versions, the assembly meets the coordination values shown in the DoC. Terminals accept 1.5…240 mm² depending on frame, with cage or box clamps that handle fine-strand when ferruled to DIN 46228. Handles are color-coded (black/grey for maintenance, red/yellow for main isolation) and provide door interlock in ON; a defeat option allows authorized opening for test. Enclosed units achieve IP65 on the face when gaskets are seated; IK ratings up to IK08 protect against site knocks. Mechanical endurance often exceeds 10–20 k cycles, electrical endurance per AC-23A is stated at In and power factor 0.65–0.8—use those numbers when planning maintenance windows.

Applications and compatibility with socomec electrical isolators

Main incomer isolation on floor DBs, local isolators next to AHUs and pumps, and lockable switches within UPS maintenance bypass cabinets are the usual placements. For drives and small motors, select AC-23A with adequate making capacity to ride through inrush; where heaters and PDU feeders dominate, AC-22A is sufficient. In PV battery rooms and DC bus ducts, use the DC-rated assemblies and respect the specified number of poles in series. For outdoor plant, choose IP65 enclosures with stainless fixings; in risers and public interiors, LSZH housings help meet building CPR strategies. Where specs mention socomec isolator switches, confirm shaft depth, door thickness, and handle footprint early so the mechanical kit lands right with the enclosure cut-outs.

Integration with other Socomec products

Switch-disconnectors sit upstream of MCCBs and downstream of changeover gear. With ATyS automatic transfer systems, the incomer isolator defines the LOTO point and must match the generator fault level—recheck conditional ratings against the upstream protective device. In UPS rooms, coordinate with maintenance bypass paths so isolation does not strand the static bypass. DIRIS meters benefit from early-make neutral auxiliaries and clean segregation; mount auxiliaries that mirror status to BMS without back-feeding the control circuit. When SPDs share the row, keep leads short and verify the fuse or MCB back-up aligns with the SPD’s Ifi so nuisance trips don’t mask a real isolation need. Field installers often pair door-coupled handles with cam-key defeat where test under live-front is authorized by the method statement.

Selection criteria for B2B clients using socomec main switch units

Start from source fault and load type.

- Rated current and category: pick In with thermal headroom and AC-22A vs AC-23A by load profile; verify electrical endurance at the intended duty.

- Short-circuit performance: check Icw and conditional rating with the upstream gG/aM fuse or MCCB; generator mode may change the let-through—validate both.

- Poles and neutral: 3P for balanced three-phase; 3P+N or 4P where measurement integrity, PME rules, or harmonic neutrals require a switched neutral.

- Mounting and IP: DIN-rail for compact boards, plate-mount for door coupling, IP65 enclosed for plant areas; confirm door thickness and shaft length.

- Interlocking and safety: padlocks in OFF, door interlock in ON, defeater policy, and auxiliary contacts for BMS status.

- Cabling: terminal size versus conductor, top/bottom entry, shrouds, and heat rise near dense busbar chambers.

When the spec calls these socomec mcb rcd devices elsewhere in the schedule, keep nomenclature clean—protection is handled by 60898/60947-2 devices, while the isolator’s job is safe disconnection under 60947-3.

socomec manual disconnect switches applications and compatibility

Site teams often need a local, visible OFF next to machinery or racks. Hand-operated mechanisms with positive break, padlock points, and clear ON/OFF legends meet the permit-to-work rules without adding electronics. Use these near UPS output frames, generator synchronizing rails, and service panels where a motorized mechanism isn’t justified; match the handle color to the safety narrative used across the facility.

Advantages of working with Bankoflamps

You get project-specific B2B pricing and a named manager who maps frames, utilization categories, pole sets, handles, auxiliaries, shaft kits, and enclosures to each board schedule and mechanical layout. The portal shows live EU stock per warehouse; quotations usually return in about an hour with EAN/MPN, conditional short-circuit tables, door thickness notes, and accessory codes. Orders go in by manufacturer part number, with downloadable price lists that carry validity windows so budgets hold through phases. We track lead times and shipment legs, consolidate by site and zone to cut off-loading time, and provide purchase-history analytics. Post-payment up to 30 days is available for trusted clients across France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.