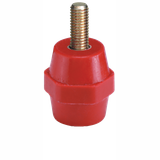

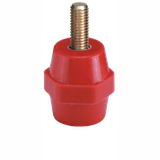

Socomec Electric box (breaker panel)

-

-

1

- 2

-

socomec distribution boards in real projects

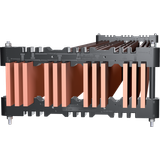

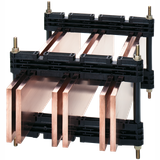

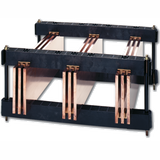

On live sites—offices, hospitals, light industry—the board must stay predictable under fault and quiet in day-to-day service. Socomec assemblies are built around verified thermal rise, clear isolation logic, and tidy cable management so commissioning doesn’t devolve into field improvisation. Typical ratings: 230/400 V AC, 50/60 Hz, busbars from 160–1250 A, short-circuit withstand to the board schedule (commonly 10–50 kA at 400 V). Indoor fronts land around IP30–IP43; plant and façade positions move to IP54–IP65 with gasketed doors. Impact resistance to IK08/IK10 keeps doors and windows intact when trolleys meet metal.

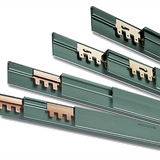

Range overview for socomec switchboards

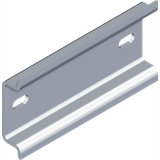

Frames come either floor-standing with front/rear access or compact sections that sit tight in risers. Device zones are organised on 35 mm rails and formable plates, with space for incomers, metering, surge rows, and final circuits. Cableways separate power, control, and data; removable gland plates simplify punching and sealing. Neutral bars are offered at 100% or 200% where single-phase electronics and triplen harmonics dominate. Mechanical kits include door-coupled handles for isolators, viewing windows above metering, and hinged escutcheons for fast FAT/SAT.

socomec modular distribution boxes for small-to-medium circuits

For floors and tenant rooms, compact boxes with 12–72 modules per door deliver dense rows of MCBs/RCBOs, SPDs, and auxiliaries. Knockouts line up with trunking; depth options protect bend radius on 10G copper and control wiring. Labels, circuit schedules, and QR sheets are placed where crews can scan without opening live fronts.

Rack and riser power with socomec power distribution units

Where IT or AV racks need structured power, unit-level PDUs and vertical strips feed A/B paths from upstream protection. Metered variants report current, voltage, and energy to BMS; locking outlets curb accidental disconnects during churn. Thermal design assumes warm aisles—derating tables and cord-set guidance are provided so plug temperatures stay in spec.

Engineering data and compliance

Assemblies are verified to IEC/EN 61439 (-1 general; -2 for power switchgear and controlgear; -3 for distribution boards for domestic/commercial). Enclosures reference IEC 62208; IP/IK per IEC 60529/62262. Clearances and creepage are dimensioned to pollution degree and overvoltage category; temperature-rise is validated with representative device loads and copper section. SPD coordination supports Type 1 at service entrances and Type 2 inside boards; total lead length target ≤0.5 m to the bus. Earthing schemes (TN-S, TT) are documented with PE bar sizing and test studs. Optional compartmentalisation (Form 2/3/4 by common industry practice) helps maintenance teams replace finals without opening incomers.

Applications and compatibility across building types

Commercial floors: lighting and socket finals with C-curve MCBs/RCBOs, Type 2 SPDs, and MID meters for cost allocation. Healthcare: higher Icn, selective residual layers, and physical segregation around lifesaving circuits. Light industry: D-curve finals for motors, Type F/B residual protection near VFDs, and larger incomers to ride step-loads. Data and broadcast: dual incomers with mechanical interlocking, metered feeders, and clear A/B busbar separation. Where the schedule names socomec electrical panels for corridors, specify fire-rated doors to the building strategy and keep escutcheon cut-outs aligned with device pitch to avoid finger gaps. For compact risers, socomec wall mounted enclosures keep depth under control without sacrificing wiring space. If a consultant asks for “spares and space” on socomec panel boards, hold 20–30% pole space and spare terminals for staged fit-outs.

Integration with related Socomec equipment

Upstream: switch disconnectors and ATyS transfer systems define lockable boundaries; confirm conditional short-circuit ratings on generator mode. Protection: MCB/RCD/RCBO rows coordinate to published I²t and selectivity tables; surge modules get documented back-up protection. Measurement: DIRIS meters tie to CT blocks with shorting links; Modbus RTU or TCP maps are reused across boards to keep commissioning fast. Power quality: keep metering VT/CT wiring in shield-friendly conduits and out of SPD magnetic loops. For UPS rooms, neutral sizing and thermal headroom are checked against crest-factor loads.

Selection criteria for B2B clients

- Source and fault level: set busbar In and board Icc to the worst-case (utility and generator).

- Circuit mix: motor/heater balance drives AC-23 versus AC-22 duty for upstream isolators and the MCB curve family downstream.

- Form factor: floor-standing with rear access for heavy cabling; shallow sections for tight risers; compact boxes where only finals are needed.

- Thermal model: verify device power loss and enclosure ventilation; don’t stack high-loss frames without spacer plates.

- Surge and metering: specify Type 1/2 SPDs and CT class/ratio at design stage; leave reserved space for shorting blocks and test points.

- Cabling discipline: select gland plate size, cable entry (top/bottom), and bending room; align with trunking heights to avoid on-site rework.

- Documentation: ask for torque charts, rail loading, and wiring diagrams per board—what many specs summarise under socomec circuit protection devices and accessories.

Procurement and build notes

Standardise on a narrow set of door sizes and depths to simplify spares. Use numbered ferrules that mirror the schematic and panel schedule. Where tenant churn is expected, adopt modular metering and pluggable SPD cartridges. For phased jobs, pre-fit blank ways and captive nuts so later additions don’t force drilling in live areas.

Advantages of working with Bankoflamps

You get a named B2B manager who maps busbar ratings, incomer style, protection rows, SPD kits, metering, enclosure depth, and cable entry to each drawing. The portal exposes real-time EU stock at warehouse level. Quotations typically arrive in about an hour with EAN/MPN, heat-rise notes, IP/IK declarations, gland-plate lists, and accessory codes. Orders are placed by manufacturer part number; downloadable price lists carry validity windows so budgets stay predictable across phases. We track lead times and shipment legs, consolidate by site and zone to reduce off-loading, and provide purchase-history analytics. Post-payment up to 30 days is available for trusted clients in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.