Socomec Circuit Breakers

socomec breakers scope and brand context

Project boards in offices, hospitals, and light industry often mix measurement, switching, and protection on the same 35 mm rail. Socomec focuses on predictable protection behavior under real fault duty: stable thermal characteristics, tight magnetic trip windows, and clean isolation markings so maintenance teams can lock out with confidence. Typical voltage classes are 230/400 V AC, 50/60 Hz; terminals are finger-safe (IP20) with cage clamps sized for 1.5…35 mm² depending on frame. Ambient operation commonly spans −25…+55 °C with derating tables for warm risers.

socomec din rail devices range and series overview

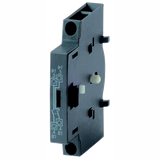

The lineup covers MCBs, RCCBs, RCBOs, add-on auxiliaries (OF/SD), shunt and undervoltage releases, phase-loss monitoring, and surge modules that share the same pitch for dense rows. Module widths follow 17.5 mm increments; pole sets include 1P, 1P+N, 2P, 3P, and 4P so single- and three-phase boards land on the same cut sheets. Field teams will notice consistent terminal geometry, rear index for busbar forks, and printed trip curves on the front label—useful when boards are crowded.

socomec miniature circuit breakers selection and curves

Ratings typically run 6…63 A for final circuits with breaking capacities from 6 kA (residential/light commercial) up to 10–15 kA for tougher panels. Magnetic curves: B ~3–5×In for resistive or long cable runs, C ~5–10×In for mixed loads, and D ~10–20×In for motors and transformers with high inrush. Let-through energy (I²t) and 3-cycle peak current data support selectivity and back-up coordination against upstream MCCBs. Verify prospective short-circuit at the board; where the PSSC exceeds the MCB’s Icn, use documented back-up with a gG fuse or upstream breaker per the coordination table.

socomec residual current breakers functions and types

RCD options cover Type AC for sinusoidal residuals, Type A for pulsating DC (common with single-phase electronics), Type F for variable-frequency drives on single-phase, and Type B for smooth DC and multi-frequency content. Sensitivities: 30 mA for personal protection, 100/300/500 mA for fire and feeder protection. Time-delayed “S” variants help achieve selectivity between floor and final circuits. RCBO frames combine overcurrent and residual trip on one pole-space to save width in retrofit boards.

Technical specifications and standards

Conformity anchors to IEC/EN 60898-1 for final-circuit MCBs and IEC/EN 60947-2 for industrial breakers where higher Icu/Ics is required. RCCBs follow IEC/EN 61008-1; RCBOs follow IEC/EN 61009-1. Dielectric and isolation ratings are printed on the device side; look for the symbol to confirm use as a disconnector. Thermal calibration assumes 30 °C ambient; apply the manufacturer’s correction factors for warm closets. Terminal torque windows are indicated on the front; use ferrules for fine-stranded conductors to prevent strand splay under vibration. For boards with high harmonic content, check neutral sizing and consider 4-pole RCDs with true 4P switching.

Applications and compatibility

Office loads: lighting, socket rings, and IT outlets sit well on C-curve 10–20 A with 30 mA RCBOs where nuisance trips must stay low yet circuits remain traceable per room. Healthcare and education often specify 10 kA Icn with selective RCD layers and labeling per circuit function. Light industry: small motors and VFD panels benefit from D-curve finals and Type F or Type B residual protection to ignore healthy leakage while catching real faults. For PV and EV supply equipment, use DC-aware residual protection and confirm upstream surge modules to keep nuisance trips in check during transients.

Integration with other Socomec products

Switch-disconnectors upstream define isolation points; ensure the prospective fault current at their terminals matches the downstream protective chain. UPS and ATS bays change fault source impedance—rework selectivity tables when the source flips to generator. DIRIS meters and gateways prefer clean neutrals; avoid shared-neutral RCD groups where harmonic currents could bias trips. When adding SPDs on the same row, preserve the lead length discipline (≤0.5 m total path) and confirm the MCB or fuse used as SPD back-up meets the device’s required Ifi.

Selection criteria for B2B clients

Start with fault duty at the board and the load profile.

- Breaking capacity and curve: size Icn/Icu to the PSSC and pick B/C/D by inrush.

- Residual function: AC/A/F/B by waveform; 30 mA where personnel exposure exists, time-delay S for upstream discrimination.

- Pole set and neutral handling: 1P+N for final single-phase, 4P where neutral switching or measurement integrity matters.

- Coordination: demand documented selectivity or energy-let-through limits against the upstream MCCB or fuse, including generator mode.

- Space and service: RCBOs shrink rows; auxiliaries (OF/SD, UVR) enable remote status and interlocking.

For specs that group these as socomec modular protection devices, lock device types, curves, and residual classes per circuit schedule early so FAT/SAT stays predictable.

Product range and procurement notes

Permanent busbar kits and fork bridges keep assembly time short, while protective shrouds and phase barriers maintain IP20 in service. For retrofit boards, use compact RCBO frames to reclaim pole spaces. Where documentation names socomec circuit protection units, request torque charts, heat-rise data, and rail loading limits with the quotation so the board shop doesn’t guess. If a project aligns MCB and RCD functions in one SKU, earmark the line items as socomec mcb rcd devices to avoid split deliveries across trades.

Advantages of working with Bankoflamps

You receive project-specific B2B pricing and a named account manager who maps curves, breaking capacities, residual types, pole sets, auxiliaries, and busbar kits to each board schedule. The portal shows real-time EU stock by warehouse; quotes typically return in about an hour with EAN/MPN, thermal derating notes, coordination references, and accessory codes. Orders go in by manufacturer code, with downloadable price lists that carry validity dates so budgets hold through phases. We track lead times and shipment status, consolidate shipments by site zone to trim off-loading time, and provide purchase-history analytics. Post-payment up to 30 days is available for trusted clients across France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.