SLV Wall mounting lamps

slv wall mounting lamps range and application

SLV wall-mounted families solve corridors, stair cores, receptions, and guest rooms where vertical illuminance, clean wiring, and quick fit-off matter. Lumen packages typically span ~500–3 000 lm with up, down, up/down, and forward-throw distributions. Color choices: 2700/3000/3500/4000/6500 K; CRI 80 for circulation and CRI 90/95 in hospitality and retail fronts. IP20/IP40 handle interiors; IP44/54 options suit washrooms and entrances; vandal-resistant housings up to IK08–IK10 protect access routes.

slv wall lights formats and optics

Forms include blade sconces with controlled forward throw, diffuse boxes for uniform verticals, and shielded cylinders for glare-sensitive sightlines. Optics range from opal diffusers (soft, even walls) to micro-prismatic lenses that keep screen-adjacent areas within UGR guidance. Asymmetric wall-wash versions lift Emin/Ē on long corridors without extra watts; baffles preserve cut-off in low ceilings and near mirrors.

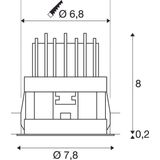

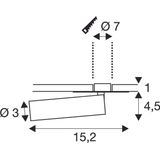

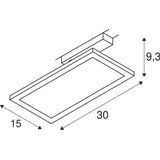

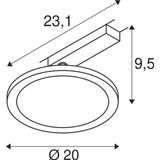

slv wall mounted luminaires technical specifications

Electrical: 220–240 V, 50/60 Hz with fixed-output or DALI-2 drivers; selected SKUs support phase-cut for fast retrofits. Power factor ≥0.90; THD typically ≤10–15 % on professional drivers. Flicker: office-ready lines target PstLM ≤1.0 and SVM ≤0.4. Thermal: Ta −20…+40 °C typical; maintain 10–15 mm air around convection-cooled drivers and respect the marked Tc. Lifetime: LM-80/TM-21 backed engines; expect L80 50–70k h at Ta 25 °C with Tc margin. Compliance: EN/IEC 60598 (safety), EN 62031 (LED modules), EN 61347 (controlgear), EMC per EN 55015/EN 61547, mains quality EN 61000-3-2/-3-3. Photometry in IES/LDT per lumen node, CCT, and optic; emergency variants provide flux files for 1–3 h modes.

Installation, substrates, and wiring practice

Back-plates accept through-wiring (typically 2×1.5–2.5 mm²) and include strain relief. Concrete prefers metal expansion anchors; plasterboard needs spreaders sized to the published point load. For damp rooms, use gasketed entries and IP-rated cable glands; route control pairs separately where DALI is specified. Keep junctions accessible—mirror-adjacent fittings often require side-entry glands to avoid visible cable shadows.

slv led wall lamps integration and controls

For grouped scenes in hotels or offices, specify DALI-2 DT6 and publish minimum stable dim level so cleaners don’t work in semi-dark. Sensor options (HF/PIR) trim after-hours energy without extra control wiring. Where phase-cut remains, prefer trailing-edge dimmers for quieter acoustics and better low-level stability; document inrush per circuit to keep MCB selection predictable.

Applications and compatibility

Corridors: asymmetric or up/down distributions improve guidance and perceived brightness with fewer fittings. Reception and lounges: 2700–3000 K, CRI 90, opal or shielded optics to protect seated eyes. Retail walls: 3000–3500 K with higher lumen nodes to support verticals; combine with ceiling accents for contrast. Washrooms: IP44/54 bodies and sealed diffusers; verify cleaning agents against diffuser material. When schedules reference slv indoor wall fixtures without extra detail, lock optic, lumen class, CCT/CRI, control method, and substrate fixings before freezing substitutions.

Selection guidance for B2B buyers

Start from target vertical lux and uniformity; pick distribution (up/down/forward/asymmetric) to hit the wall plane with minimal glare. Choose CCT/CRI by space type; standardize two lumen nodes per floorplate to stabilize commissioning across varied ceiling heights. Validate back-box positions and conduit entry early; mirrored pairs need consistent cable exit geometry. For aesthetic briefs tagged as slv decorative wall lighting, align envelope sizes and finishes across the sightline so joins and trims read consistently.

Ecosystem fit and mixed schemes

Wall runs coordinate with SLV recessed and surface families on the same dimming protocol, simplifying scenes and maintenance. Where pendant accents share circuits, publish channel loads and emergency logic together. Feature walls often pair sconces with linear coves; voltage-drop and driver headroom should be calculated for those companion lines during the same submittal.

Advantages of working with Bankoflamps

You get individual B2B pricing and a named account manager who maps optics, lumen nodes, drivers, anchors, finishes, and emergency options to your room data sheets and reflected ceiling plans. Our portal shows live EU stock by warehouse; quotes typically return in about an hour with EAN/MPN, photometry, Tc limits, PF/THD, inrush, IP/IK, mounting patterns, and conduit notes—so coordination stays tight. Orders go in by manufacturer code with downloadable, always-current price lists and validity windows. We provide lead-time tracking, order status, and purchase-history analytics; trusted clients can use post-payment up to 30 days. Shipments are consolidated by line and zone to cut freight and site sorting, and we actively support projects in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.