SLV Surface mounting lamps

slv surface mounting lamps range and context

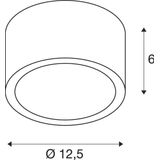

Surface-mount SLV families solve corridors, stair cores, lobbies, and small offices where void depth is tight or the ceiling can’t be penetrated. Form factors include shallow circular drums, compact cylinders, wafer panels, and linear bars for perimeter guidance. Lumen packages typically span ~800–5 000 lm with distributions for general wash, corridor/asymmetric guidance, and low-UGR work zones. Color options 2700/3000/3500/4000/6500 K; CRI 80 for back-of-house and CRI 90 where rendering matters at reception or retail fronts. IP20/IP40 covers interiors; IP44/54 variants handle washrooms and entrances; selected vandal-resistant bodies reach IK08–IK10 for stairwells.

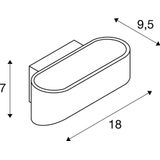

slv wall mounted luminaires formats and optics

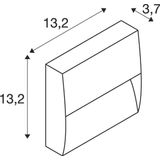

Wall versions arrive as up/down cylinders, blade sconces with forward throw, and diffuse boxes for circulation spaces. Optic choices include opal diffusers for uniform verticals, micro-prismatic lenses to control glare near screens, and shielded up/down slots where contrast is part of the brief. Emergency variants keep route lighting legal without breaking the visual rhythm; sensor options (HF/PIR) manage after-hours energy without extra control wiring.

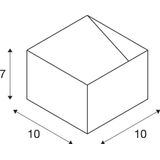

slv ceiling surface lights technical specifications

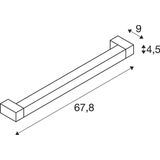

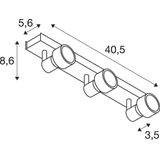

Electrical: 220–240 V, 50/60 Hz. Drivers in fixed-output or DALI-2; phase-cut available for quick retrofits. Power factor ≥0.90 with THD ≈10–15 % on pro drivers. Flicker: office-ready families meet PstLM ≤ 1.0 and SVM ≤ 0.4. Lifetime: LM-80/TM-21 backed modules; expect L80 50–70k h at Ta 25 °C when Tc is respected. Thermal window commonly −20…+40 °C; maintain 10–15 mm air around convection-cooled drivers. Photometry: IES/LDT per CCT and lumen node. Compliance: EN/IEC 60598 (safety), EN 62031 (modules), EN 61347 (controlgear), EMC per EN 55015/EN 61547, mains quality EN 61000-3-2/-3-3. Diffusers: opal for comfort, micro-prismatic where UGR targets apply; linear bars offer batwing or asymmetric distributions to lift Emin/Ē in long passages without extra watts.

slv surface led fixtures applications and compatibility

Corridors benefit from asymmetric linear bars to pull light onto walls and improve guidance. Offices and classrooms pair low-UGR cylinders or wafers at 4000 K for even task zones. Hospitality uses warm 2700–3000 K drums with opal covers to avoid bright points in low ceilings; lobby feature walls lean on up/down sconces for contrast. Utility rooms and back-of-house take IP44/54 domes with robust diffusers and tamper-proof screws. Where specs call for slv decorative surface lamps, match envelope size, diffuser type, and finish so trims align across the sightline.

Integration with SLV ecosystems

Surface families align with tracks, pendants, and recessed lines in the same palette. Use frames/adapters where legacy holes need regularizing or where conduit enters from surface trunking. If a space mixes accents and background light, keep one protocol (DALI-2 preferred) across downlights, linears, and these housings; it simplifies commissioning and scene logic. For heritage areas that must stay surface-run, document conduit entry positions and gland sizes so slv surface installation luminaires land cleanly on existing junctions.

Selection criteria for B2B clients

Start with target illuminance and uniformity, then choose lumen node and optic. Lock CCT/CRI per space class. Decide control early—DALI-2 for schedules and analytics; phase-cut only where control wiring is impossible. Validate substrate and fixings: concrete prefers metal expansion anchors; plasterboard needs spreaders to the published load. Publish inrush and channel counts in the panel schedule; nuisance MCB trips vanish when these numbers are agreed. Confirm overall height and side-entry clearance for conduits. For portfolio consistency across floors, standardize two lumen nodes (low/high ceiling) and one finish RAL. If a package note references slv mounted lighting systems, align wall and ceiling pieces so junction heights and spacing are repeatable.

Advantages of working with Bankoflamps

You receive individual B2B pricing and a dedicated account manager who maps optics, lumen nodes, drivers, fixings, and emergency options to your room data sheets and reflected ceiling plans. Our portal shows live EU stock by warehouse; quotes typically return in about an hour with EAN/MPN, photometry, Tc limits, PF/THD, inrush, IP/IK, mounting patterns, and conduit entry notes—so coordination doesn’t drift. Orders go in by manufacturer code with downloadable, always up-to-date price lists and validity windows. We provide lead-time tracking, order status, and purchase-history analytics; trusted clients can use post-payment up to 30 days. Shipments are consolidated by line and zone to cut freight and site sorting, and we actively support projects in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.