SLV LED Panels

slv led panels Application scope and performance

Open-plan offices, classrooms, clinics, and retail back-of-house all want the same thing: stable illuminance, low glare, and drivers that behave on crowded lighting feeders. SLV panel families cover 600×600, 300×1200, 620×620 and other regional formats with lumen nodes ~2 000–7 000 lm, efficacies typically 110–140 lm/W, CRI 80/90 options, and CCT 3000/3500/4000/6500 K. Driver PF ≥0.90 and THD ≤10–15 % on professional lines keep harmonic budgets civil; inrush data is published so breaker diversity is engineered, not guessed. Most series run −20…+40 °C, with surge immunity 2–6 kV (line-to-line / line-to-PE) when correctly bonded.

slv recessed panel luminaires Optics, grids, and UGR

Diffuser stacks use micro-prismatic films or structured PMMA/PC to hit UGR targets in VDT spaces (≤19 over desks is common when mounting and spacing are respected). Edge-lit variants give slim construction and uniform luminance; direct-lit boards with optical plates win when very low UGR or higher punch is needed. LDT/IES files include batwing distributions for evenly lit workplanes; keep Emin/Ē ≥0.6 in offices and ≥0.4 in circulation. Binning is tight (≤3 SDCM) so long corridors don’t show color seams. Where cameras live, pro drivers meet PstLM ≤1.0 and SVM ≤0.4 for low-flicker scenes.

slv ceiling panel lights Electrical design and standards

Safety and control gear follow EN 60598-1/-2-2 and IEC/EN 61347-2-13. EMC complies with EN 55015; immunity with EN 61547; harmonics per EN 61000-3-2 Class C (>25 W). Wiring windows typically 0.5…2.5 mm²; torque and strip lengths are printed on the card so QA doesn’t pause at height. Lifetime claims are tied to LM-80/TM-21 data—L80 50–100 kh at rated Tc is realistic when the plenum isn’t cooking the gear. IP ratings are generally IP20 for interiors; IP40/IP54 options exist for dusty or damp ceilings. Emergency choices include integral 1–3 h packs or central-battery kits with documented EM flux.

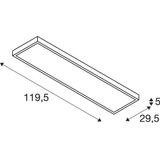

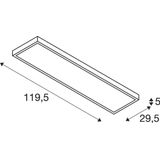

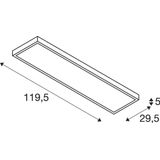

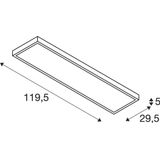

slv surface mounted panels Mounting, thermal, and retrofit notes

Surface frames and low-profile housings land on plasterboard or concrete without re-gridding. Rigid frames stop “oil-canning” on large plates, and captive screws speed ceiling time. Keep 10–15 mm air around convection-cooled drivers; crowded voids push Tc over spec and eat lifetime. For retrofit troffers, adapter skirts mask legacy openings; through-wiring variants simplify daisies on 10 A lighting circuits. Where dust or aerosols are present (print rooms, kitchens outside hoods), specify sealed faces and gasketed frames to keep optics clean.

Integration with controls and networks

DALI-2 (DT6) is the default for zoning; DT8 supports tunable white in meeting rooms and classrooms. 1–10 V remains viable for simple areas; publish minimum stable dim level so cleaners aren’t left in semi-dark. Hold DALI loop current ≤250 mA with ~20 % headroom, observe cable-length limits, and coordinate presence/daylight sensors on the same loop. Upstream, use Type 2 SPDs in the lighting DB and keep VFD feeders segregated to stop EMC ghosts being misdiagnosed as “panel flicker.”

Selection criteria for B2B buyers

- Targets first. Desk zones 500–750 lx (UGR ≤19), corridors 100–200 lx; pick lumen node and optic to hit Ē and Emin/Ē.

- Ceiling system. T-grid vs plasterboard vs concrete; check cut-out, frame depth, and anchor type.

- Electrical discipline. PF/THD limits, inrush (A/µs) per circuit, surge class, wiring window; verify Zs after LED load reductions.

- Controls. Protocol (DALI-2/1–10 V), address budget, min level, and fade curves—write them in the spec.

- Visual comfort. UGR claim at your mounting height/spacing, not generic; confirm shielding and luminance.

- Serviceability. Gear access, spare diffusers, visible Tc mark; keep Tc 10–15 K below limit for warranty headroom

Use slv office lighting panels when you need a straight-through UGR ≤19 deliverable across open offices; note the exact grid size, optic type, and driver protocol on each tag so procurement can’t substitute look-alikes.

Applications and compatibility

Education: batwing optics and DT8 tunable white for circadian profiles. Healthcare: sealed faces, high-CRI options for examination zones, and low flicker for imaging rooms. Retail back-of-house: medium UGR sheets with through-wiring to speed re-fits. Where ceiling height or architectural intent demands ultra-low profiles, slv slim led panels sit tight to the slab while holding uniformity. In modular ceilings with mixed cut-outs, treat runs as slv modular panel lights to maintain sightlines and spares logic across sizes.

Installation practice and field notes

Publish ferrule sizes and torque on the drawing; over-compression ruins terminals and IP seals. Stagger start or specify soft-start drivers on AFDD/B-curve circuits. Feed diversity matters: start large nodes a few hundred milliseconds apart or split by row. Leave cable slack and label loops; maintenance lives or dies on neat marshalling. In dusty builds, order spare gasket sets with the first drop—most “panel failures” are ingress after a rushed service call.

Advantages of working with Bankoflamps

We translate lumen nodes, optics, UGR targets, control protocol, and frame geometry straight from your room data sheets and one-lines, then show live EU stock by warehouse before access nights are booked. Quotes usually land in about an hour with EAN/MPN, Tc limits, PF/THD, inrush, IP class, emergency mode, and frame kits spelled out—so selections don’t drift mid-phase. Your portal provides lead-time visibility, shipment status, and downloadable price lists with validity dates; approved clients can use post-payment up to 30 days. We consolidate by floor or zone to cut freight and on-site sorting, and your account manager cross-checks cut-out and grid sizes, breaker diversity, DALI budgets, emergency zoning, and ceiling build-ups against the drawings—so cartons arrive lift-ready and crews close the ceiling once.