SLV In-ground luminaires

slv in ground luminaires Application scope and brand context

Wayfinding on plazas, hotel drives, waterfront promenades, and façade uplighting all rely on fixtures that survive wheels, salt, and freeze–thaw cycles. SLV’s ground-recessed range is built around die-cast or stainless housings, thick tempered glass, and silicone gaskets that keep seals stable after the third maintenance cycle. Lumen nodes span ~400 to 6 000 lm with beam choices from 10° punch to wide flood and wall-wash; CCT 2700/3000/4000/5000 K, CRI 80/90 options, PF ≥0.90, and low-flicker drivers suited to cameraed sites. Ambient operation typically −20…+50 °C; cold-climate kits and marine finishes are available by series. On demanding exterior projects, in-ground fittings are usually split by role. Heavy-traffic plazas, campus routes and forecourts are often built on robust siteco in ground luminaires and rzb in ground luminaires to ensure long service life and stable optics. Where clients want a global reference brand for public or corporate sites, planners commonly standardise key zones on philips in ground luminaires, while decorative residential, hospitality and small commercial entrances are often completed with nowodworski in ground luminaires to match the overall façade and landscape design.

slv recessed ground lights Construction, optics, and mechanics

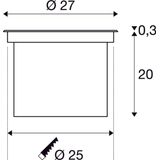

Bodies use corrosion-resistant alloys with polymer sleeve pots that decouple the luminaire from concrete; this reduces thermal stress and eases replacement. Faceplates arrive round or square with anti-slip glass; glare is managed via regress, snoots, or honeycomb louvres. Aimable versions include ±15–20° tilt under the glass for accurate façade picks without breaking grade. Drive-over classes are stated (e.g., 2 000–5 000 kg static, axle load declarations), with IK09/IK10 impact fronts and IP67/IP68 sealing when the sleeve, drain bed, and gland stack are assembled per the guide. Cable windows typically 1.0…2.5 mm²; through-wiring on selected models simplifies daisy chains along paths.

slv inground led lights Technical specifications and standards

Safety: EN 60598-1 and EN 60598-2-13 (recessed floor). Control gear: IEC/EN 61347-2-13. EMC: EN 55015 emissions, EN 61547 immunity; harmonics per EN 61000-3-2. Optics verified to LM-79; source maintenance from LM-80/TM-21 (common claims L80 50–100 kh at rated Tc). Surge pathways 4–6 kV line-to-line (series dependent); pair with Type 2 SPD at the board for long feeders. Thermal notes: driver cavities are isolated from the LED engine; Tc marks are visible from the top after the bezel lifts. Gland interfaces accept M16/M20 with specified torque—over-compression is the usual cause of IP loss after year one.

Installation engineering that passes inspection

- Sleeve and drain: sit the pot on a 150–200 mm graded aggregate bed, add side weeps to avoid standing water; geotextile prevents fines migration.

- Concrete pour: decouple with expansion foam; keep top flush, not proud—snowploughs and sweepers punish edges.

- Cables: use gel-filled joints below grade; maintain minimum bend radii and keep junctions outside the sleeve.

Chemistry: for coastal or de-icing salts, specify 316 faceplates and anodised/epoxy bodies; verify ISO 9227 class. - Glare control: pick regress or accessories where lines of sight are low; aimable optics help keep luminance off drivers’ eyes.

slv ground fixture luminaires Applications, controls, and integration

Façade uplight: narrow beams on columns, elliptical for pilasters, and wall-wash for stone fields—publish tilt/offset so the contractor doesn’t re-aim by eye. Plaza markers: low-output guides on 3000 K with anti-slip glass and uniform spacing to achieve ≥0.2 lx minimum. Tree/landform accents: wide flood with CRI 90 near warm materials. Car courts: drive-over frames with stainless fasteners and high-friction glass. Controls: DALI-2 DT6 for intensity, DT8 for tunable-white sequences on heritage sites; 1–10 V works for simple scenes. Nodes can ride Zhaga Book 18 bollards and trigger scenes alongside the same loop. For project notes that call the category slv outdoor in ground lighting, align IP class, drive-over rating, glare policy, and sleeve detail on each tag.

Electrical and civil coordination

Keep feeders segregated from VFD circuits; bond gland plates 360° in control pits. Voltage drop matters on long runs—step to 48 V CV systems or feed both ends to maintain CCT uniformity where strips accompany ground points. Coordinate cut sheets with civil elevations: sleeve depth, finish grade, and drainage plane must be explicit. Where landscape architects specify slv landscape lighting generically, lock beam codes and aiming geometry early to prevent RFIs.

Performance, maintenance, and field data

Dirt depreciation is real at ground level—publish LLF assumptions in the calc pack and set quarterly clean cycles on coastal or dusty sites. Keep Tc 10–15 K below limit; crowded pits cook drivers. Stock spare gaskets and glass—most service calls are water ingress after third-party maintenance. Anti-seize on stainless threads avoids snapped screws during winter pulls. If a tender bundles marker studs and uplights under slv buried luminaires, separate drive-over from walk-over classes in procurement to avoid the wrong faceplates arriving.

Selection criteria for B2B buyers

- Duty and class: walk-over vs drive-over; define axle/static load and IK.

- Optic/beam: 10–15° façade punch, 30–60° flood, ellipses for tall/narrow surfaces; set tilt/offset in the tag.

- Environment: IP rating, corrosion class, de-icing exposure; specify 316 and coated bodies where needed.

- Electrical: PF/THD targets, inrush per circuit, surge path, conductor window; confirm Zs after LED load reductions.

- Controls: protocol, channel count, minimum stable dim level; reserve DALI addresses with ≥20 % headroom.

- Civil: sleeve size, drain bed, weeps, grout/finish details; avoid placing fixtures inside ponding zones.

- Documentation: IES/LDT, LM-80/TM-21 nodes, torque, gland sizes, and cleaning schedule—auditors stop asking when these are present.

Advantages of working with Bankoflamps

We map optics, lumen nodes, load class, sleeve and drain details, driver type, and control topology to your road books and landscape plans, then present live EU stock by warehouse before night works are booked. Quotes typically return in about an hour with EAN/MPN, IP/IK and drive-over ratings, surge class, inrush, torque, gland sizes, and sleeve kits—so civil and electrical trades stay in lockstep. Your portal shows lead times, shipment status, and downloadable price lists with validity dates; approved clients can use post-payment up to 30 days. We consolidate by zone or elevation to cut freight and on-site sorting, and your account manager checks drainage, corrosion class, feeder diversity, CMS policy, and mounting hardware against the drawings—so cartons arrive pit-ready and crews set once.