SLV Ceiling mounting lamps

slv ceiling mounting lamps range and context

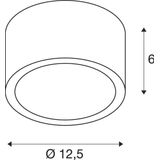

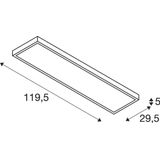

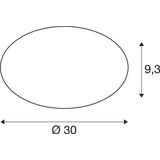

SLV ceiling-mounted solutions cover everyday rooms, corridors, stair cores, and small lobbies where a tidy housing, predictable photometry, and fast fit-off matter. Lumen packages typically span ~800–5 000 lm with distributions for general wash, corridor guidance, and low-UGR work zones. Color options run 2700/3000/3500/4000/6500 K; CRI 80 for back-of-house and CRI 90 where color rendering helps retail or reception areas. Families include shallow circular drums, square panels, compact cylinders, and IP-rated domes for utility rooms and entrances.

slv mounted ceiling luminaires product families and formats

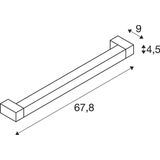

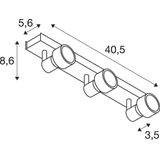

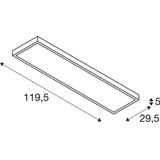

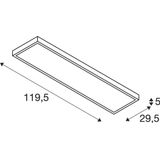

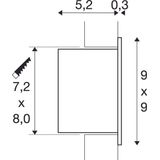

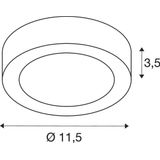

Choose fixed-output or DALI-2 dimmable drivers; phase-cut variants exist for quick retrofits. Housings are powder-coated steel or die-cast aluminum; opal diffusers deliver uniformity while micro-prismatic lenses keep screen-adjacent areas within UGR guidance. Low-profile models sit 40–70 mm off the plane for tight voids; deeper cylinders manage higher watt densities and better glare cut-off. IP20/IP40 units serve interiors; IP44/54 tackle washrooms; vandal-resistant bodies with IK08–IK10 protect stairwells and access corridors.

slv led ceiling lights technical specifications and standards

Electrical: 220–240 V, 50/60 Hz. Typical power factor ≥0.90, THD ≤10–15 % on pro drivers. Light quality: ≤3 SDCM binning for consistent ceilings, optional CRI 90/95 on selected lines. Flicker metrics for offices are available (PstLM ≤1.0, SVM ≤0.4) when the control spec demands it. Thermal: Ta −20…+40 °C common; respect the marked Tc and keep insulation clear of driver recesses. Lifetimes: L80 50–70k h under TM-21 projection with maintained Tc. Compliance: EN/IEC 60598 for luminaire safety, EN 62031 for LED modules, EMC via EN 55015/EN 61547, mains quality per EN 61000-3-2/-3-3. Emergency: maintained and non-maintained kits available; request flux files for 1–3 h modes to validate escape-route lux.

slv ceiling mount luminaires applications and compatibility

Corridors benefit from elongated or asymmetric distributions that lift Emin/Ē without extra watts. Open offices take micro-prismatic optics for glare discipline around screens. Hospitality areas prefer warm 2700–3000 K with opal covers to avoid bright points in low ceilings. For washrooms and back-of-house, sealed IP44/54 domes handle humidity and cleaning cycles. Where the schedule simply states slv ceiling lights, confirm output node, optic, CCT/CRI, control method, and mounting pattern before freezing substitutions.

Product integration and ecosystem fit

Units align with SLV frames where legacy cut-outs need regularizing, and with matching conduits/canopies when power drops from surface trunking. Combine perimeter accents from ribbon systems on the same protocol to keep commissioning straightforward. Pendant focal points can share circuits if scenes are grouped; suspension kits handle those loads while the ceiling-mount bases deliver background illuminance.

Selection criteria for B2B clients

Start with the target illuminance and uniformity, then pick lumen class and optic. Lock CCT/CRI per space category, and choose the control path early: DALI-2 for fleets and schedules, phase-cut only where panels can’t accommodate control lines. Validate ceiling substrate and fixing—concrete takes expansion anchors; plasterboard needs spreaders sized to the load. Publish inrush per channel, emergency flux, and driver topology in the panel schedule. For tight ceiling zones, confirm overall height and cable entry clearance; shallow housings often require side-entry glands. Where spec notes mention slv surface ceiling fixtures, verify IP/IK and diffuser material to match cleaning regimes.

Integration with other SLV categories

MR16 retrofit heads remain on legacy projects; pair those with documented controlgear where needed and keep mains variants driver-integrated for faster maintenance. If the drawing calls out slv indoor ceiling lamps in mixed rooms, coordinate beams and scenes with adjacent tracks and linear accents so contrast ratios stay within the lighting brief.

Advantages of working with Bankoflamps

We map luminaires, optics, lumen nodes, drivers, anchors, and emergency options to your room data sheets and reflected ceiling plans, then show live EU stock by warehouse before access nights are booked. Quotes typically return in about an hour and include EAN/MPN, photometry, Tc limits, PF/THD, inrush, IP/IK, and mounting codes—so coordination doesn’t drift mid-phase. Orders go in by manufacturer code with downloadable, always-current price lists and pricing validity windows. Your portal provides lead-time tracking, order status, and purchase-history analytics; trusted clients can use post-payment up to 30 days. We consolidate shipments by line and zone to cut freight and site sorting, and our team supports projects in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.