SLV Built-in mounting lamps

slv built in mounting lamps range and context

SLV built-in solutions are specified where the ceiling should read clean while delivering precise, repeatable photometry. Families cover round and square apertures from ~68–200 mm, fixed and gimbal variants, and trimless plaster-in frames for invisible edges. Output nodes span ~600–5 000 lm with beams from 12° narrow spot to 60° wide flood. Color packages include 2700/3000/3500/4000/6500 K; CRI 80 for corridors and back-of-house, CRI 90/95 for retail, hospitality, and galleries. Binning sits at ≤3 SDCM in pro lines so long grids stay uniform. IP20 dominates interiors; IP44/54 front sealing is available for washrooms and entrances.

slv recessed luminaires product families and optics

Choose compact fixed downlights for general wash, adjustable gimbals for accenting, and wall-wash optics where verticals drive the brief. TIR lenses generate tight center intensity for tall spaces; hybrid reflector systems soften edges for restaurant tables. Low-glare variants use deep-set light engines and honeycomb or micro-baffle options to keep UGR within office guidance. Trim formats include classic trim, micro-trim, and trimless plaster-in kits; depth collars handle 9–25 mm boards so installers land the bezel perfectly flush.

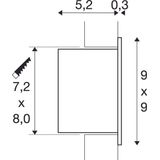

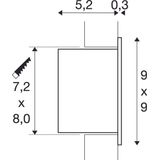

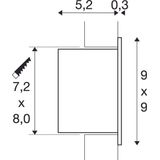

slv flush mount lamps mechanical design and thermal behavior

Housings are die-cast aluminum or formed steel with high thermal conductance paths to the heat sink. Shallow bodies (45–70 mm) solve tight voids; deeper cans improve cut-off and lumen handling. Clip options include torsion springs, butterfly springs, and M4/M5 screw tabs for concrete or cast-in boxes. Maintain 10–15 mm air around drivers; crowding pushes Tc over its mark and shortens life. Where acoustic ceilings are used, spreader plates distribute load and prevent tile creep.

Technical specifications and standards

Electrical: 220–240 V, 50/60 Hz with fixed-output or DALI-2 drivers; phase-cut variants exist for retrofit. Power factor ≥0.90 typical; THD ≤10–15 % on pro drivers. Dimming: DALI-2 DT6 for intensity, DT8 on selected tunable white engines; 1–10 V available for legacy controls. Flicker performance can meet office targets (PstLM ≤1.0, SVM ≤0.4) when specified. Lifetime: LM-80 source data with TM-21 projections; expect L80 50–70k h at Ta 25 °C when Tc is respected. Operating window commonly −20…+40 °C. Safety and EMC align with EN/IEC 60598 for luminaires, EN 62031 for LED modules, EN 61347 for controlgear, EN 55015/EN 61547 and EN 61000-3-2/-3-3 for mains quality. Photometry is provided per CCT/beam in IES/LDT for lighting calculations.

slv ceiling recessed lighting applications and compatibility

Corridors benefit from asymmetric or batwing distributions that lift Emin/Ē without adding watts. Open offices use low-UGR combinations of deep-set engines and micro-prismatic lenses near screens. Fashion and food retail lean to CRI 90+ with R9>50 and 15–24° beams for punch on merchandise. Hotels prefer warm 2700–3000 K with 24–36° beams for tables and reception islands, plus trimless frames in lobbies where a seamless ceiling matters. Washrooms and back-of-house specify front IP44/54 and vandal-resistant diffusers. When the note reads slv built in led fixtures with no more detail, lock the cut-out, beam, lumen node, CCT/CRI, and driver protocol before releasing drawings.

Integration with other SLV products

Recessed heads align with SLV frames, adapter plates, and cast-in boxes so mechanics fit the ceiling system you’ve drawn. For perimeter effects, combine downlights with linear SLV ribbon systems on the same DALI universe to keep scenes coherent. Where pendants share the space, SLV suspension kits handle those loads while the recessed grid carries baseline lux. Legacy MR16 housings can be converted using compatible lampholders and drivers; document minimum-load behavior when any 12 V circuits remain.

Selection criteria for B2B clients

Start from target illuminance and contrast. Choose beam and cut-off to hit the task plane without glare—deeper regress for offices, tighter beams for displays. Confirm ceiling type and finished thickness; pick the clamping method accordingly. Validate void depth for both can and driver, including bend radii on supply cables. Publish inrush, PF/THD, and emergency flux files into the panel schedule early; nuisance MCB trips disappear when those numbers are agreed. On multi-floor roll-outs, standardize two lumen nodes (low/high ceiling) to stabilize commissioning, and reserve trimless only where plaster works are in scope. Where a design brief calls for slv integrated mounting lamps, map aperture families across the floorplate so spares remain interchangeable.

Advantages of working with Bankoflamps

You receive individual B2B pricing and a named account manager who aligns apertures, beams, lumen nodes, drivers, frames, and emergency options to your room data sheets and reflected ceiling plans. Our portal shows live EU stock by warehouse; quotes typically return in about an hour with EAN/MPN, cut-outs, clamping ranges, photometry, Tc limits, PF/THD, inrush, IP notes, and mounting codes so coordination stays tight. Orders go in by manufacturer code with downloadable, always up-to-date price lists and validity windows. We track lead times and order status, provide purchase-history analytics, and extend post-payment up to 30 days for trusted clients. Shipments are consolidated by line and zone to reduce freight and site sorting, and we actively support projects in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.