Siemens Luminaires

-

-

1

- 2

-

siemens luminaires portfolio for projects

Engineered for consistent photometrics and long service intervals, Siemens fixtures cover task, ambient, and accent roles across industrial plants, offices, and public interiors. Families are built around high-efficacy LED engines, thermal paths sized for L90 maintenance, and drivers with stable output ripple for camera-friendly spaces. Photometric files (IES/LDT), wiring diagrams, and mounting templates are supplied so drawings move cleanly from design to the shop floor.

Product range and series overview

Linear trunking for production aisles, IP65/IP66 vapour-tight battens for washdown zones, compact high-bays for 6–18 m mounting heights, and surface/suspended panels for meeting rooms form the core set. Downlights with tight beam control handle corridors and lobbies; adjustable projectors shape merchandise or exhibit light. Emergency variants include integral battery or central-battery heads with automatic test. Drivers are fixed-output, DALI-2, or wireless-ready; optics span Lambertian, narrow, aisle, and asymmetric wall-wash. Color choices run neutral architectural whites with RAL options on request.

Other Siemens products

siemens industrial luminaires applications and mounting

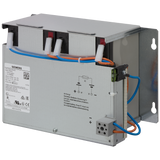

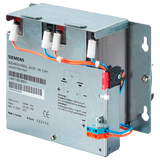

Foundries, logistics halls, and food plants benefit from sealed housings, IK08–IK10 impact resistance, and optics that hold aisle uniformity at typical 8–12 m heights. Surface, chain, rod, or trunk-rail mounting keeps install flexible; through-wiring supports continuous runs without external junctions. Specify 4–6 kV surge protection on mains and 2 kV on control lines where switching transients or large drives are present.

siemens office lighting visual comfort and controls

Open offices, focus rooms, and classrooms require low flicker and controlled luminance. Unified glare ratings ≤19 are achievable with micro-prismatic or dark-light optics. Presence and daylight sensors trim kWh without hurting user comfort, while scene control integrates with meeting-room AV for smooth transitions from presentation to discussion.

siemens architectural lighting design intent and optics

Reception zones and circulation areas call for high color rendition and clean cutoff. Wall-wash and asymmetric beams lift vertical illuminance for signage and wayfinding. Tunable-white options support 2700–6500 K profiles so designers can track brand palettes or circadian schedules without re-aiming fixtures.

Technical specifications and standards

Luminous efficacy typically 120–180 lm/W depending on optic and CCT. Lifetime options to L90B50 50,000–70,000 h or L80B10 ≥100,000 h, validated via LM-80 data with TM-21 projections at rated Ta. CCT sets: 2700/3000/3500/4000/5000/6500 K; CRI ≥80 standard with CRI ≥90 for retail and healthcare touchpoints. SDCM ≤3 on office-grade ranges keeps color uniform across batches. Power factor ≥0.90, THD <15 % for mainstream drivers; inrush and in-circuit breaker tables are published to size MCBs correctly.

Ingress and impact: IP20 office, IP54 plant rooms, IP65/IP66 wet areas; IK07–IK10 by family. Thermal window typically −25…+45 °C with high-bay variants up to +55 °C depending on lumen package. Photobiological safety assessed per EN 62471 (RG0/RG1 common). Safety and performance per IEC/EN 60598-1/-2-xx and EN 62722; EMC per EN 55015 and immunity per EN 61547. Flicker index and percent flicker are documented against IEEE 1789 guidance for task spaces with cameras. Emergency options comply with EN 60598-2-22 and provide 1–3 h autonomy.

Applications and compatibility

Production aisles need narrow or aisle optics to hold Eav with fewer poles; cold stores favor sealed housings and drivers rated for low Ta. Laboratories and healthcare offices adopt CRI ≥90 with 4000 K for accurate rendering on worktops. Galleries use precise cutoff to avoid spill. For retrofits, check ceiling grid dimensions and existing pole spacing; photometry should meet target maintained lux with room cavity ratios that match the real space. Where glare control is critical, choose louvre or micro-prism configurations and verify UGR tables for the assumed observer geometry. As part of an energy upgrade, siemens led lighting pairs with presence/daylight control to capture the last 15–25 % savings beyond simple lamp-for-lamp swaps.

Integration with other Siemens systems

DALI-2 drivers bind into room or floor controllers with group, scene, and emergency test commands. Gateways expose status to BMS for energy dashboards and fault tickets. KNX and BACnet nodes coordinate scheduling with HVAC, while dry-contact inputs suit simple time-clock schemes. Panel space is predictable: DIN gateways, surge protection devices, and automatic test modules share the same depth profile as Siemens power and control hardware, simplifying enclosure layouts. Where lines include conveyors or inspection cameras, strobing interfaces can synchronize light with machine cycles without introducing measurable ripple on the general task layer.

Selection criteria for B2B clients

Start from the target task illuminance and uniformity by area, then pick optic and mounting height to minimize poles. Fix CCT/CRI from the visual task; CRI 80/4000 K suits general admin, CRI 90 where color decisions matter. Verify UGR against the actual room geometry; don’t rely on generic tables. Choose driver type by control philosophy: fixed-output for simple replacements, DALI-2 where BMS needs telemetry, wireless for phased projects without control cabling. Check thermal limits at worst-case ambient; derate high-bay lumen packages above +40 °C. Confirm surge levels relative to the site’s SPD scheme and earthing system. In maintenance-heavy zones, quick-connects and through-wiring reduce downtime. If procurement lists siemens technical luminaires for task benches or inspection bays, lock beam angle and CRI early to avoid rework during FAT.

Advantages of working with Bankoflamps

You get project-level pricing tied to your lighting layout, a named account manager, and live EU stock visibility before shutdown or access windows are booked. Quotations with EAN/MPN typically land in about an hour and include lumen package, optic code, driver type, emergency option, and SPD notes to stop scope drift. The portal shows real-time lead times, shipment status, downloadable price lists, and purchase-history analytics. Approved clients can use post-payment terms up to 30 days. We consolidate shipments by area or floor to cut freight and site sorting, hold pricing with validity dates that match project gates, and support teams across France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands while cross-checking UGR targets, emergency coverage, mounting depths, control topology, and breaker/inrush tables against your drawings.