Siemens Frames for switches and sockets

siemens frames for switches and sockets portfolio and fit

Frames set the visible geometry of a wall grid. Siemens keeps tolerances tight so rockers, sockets, dimmers, and data apertures sit flush on uneven plaster. Euro boxes use 60 mm screw centers; UK patterns are 60.3 mm. Single to 4-gang widths are standard, with multi-aperture horizontals for hotel headboards and bench runs. Spacer rings (≈3–10 mm) correct shallow plaster; leveling shims remove gaps along tiled lines. IP20 is the default; when paired with gasket kits, compatible inserts reach IP44/IP55 for corridors and utility rooms. Impact classes up to IK07–IK08 are available for public zones.

siemens modular frames formats and grids

Choose flat, stepped, or slim-bezel variants depending on shadow lines and furniture clearance. Horizontal and vertical stacks share the same grid, so a 2×2 composition carries the same sightline as a 4-gang horizontal—useful in elevators and slim shafts. Aperture rail heights are matched across ranges, preventing the “step” that appears when mixing mechanisms from different families. Frames accept locator LEDs, engraving windows, and blind fillers without weakening posts or screw bridges.

siemens cover plates materials and protections

Fronts are thermoset for high heat resistance or UV-stabilized ABS where impact is a priority; brushed metal looks are available with insulated carriers to maintain creepage at 250 V. Glow-wire ratings are 650–850 °C (finish dependent). Operating window is typically −5…+40 °C; storage to −25…+70 °C. Cleaning chemistry matters in hospitality and healthcare, so Siemens publishes solvent lists per finish. Micro-texture options hide swirl marks from daily wipe-downs. For semi-exterior corridors, pick plates validated with splash collars, stainless fixings, and sealed locator LED windows.

Other Siemens products

siemens wall frame systems installation and alignment

Installers work faster when mechanics don’t fight them. Back-frames provide anti-rotation tabs, long slots for ±3–4 mm of screw play, and captive screws that won’t drop into cavities. Multi-gang rails keep rocker pivots co-planar; that preserves touch feel across a run. Depth control is explicit: short-body adapters protect terminal bend radii in 35 mm boxes; longer collars seat neatly in 47 mm recesses with loop-in wiring. Where dimmers cluster, spacer pieces maintain an air gap so face temperature stays within comfort expectations.

Technical specifications and standards

- Compliance with IEC/EN 60669-1 (switch furniture), 60669-2-1 (electronic controls behind plates), and IEC 60884-1 (socket-outlets).

- Ingress per EN 60529: IP20 plates; IP44/IP55 when frames, gaskets, and compatible inserts are combined correctly.

- Mechanical: plate retention tested >150 N pull; clip cycles verified for repeated service access.

- Fire and smoke: halogen-free options; LSZH plastics available where building strategy requires CPR-aligned wiring routes.

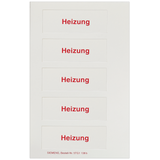

- Identification: engraving windows and label frames sized to typical 4–5 mm cap height fonts for legibility across corridors.

Applications and compatibility across building types

Apartments and hotels: standardize two neutral finishes (e.g., matte white plus brushed metal) across rooms and corridors; add locator LEDs near access-control readers. Offices and classrooms: adopt flat bezels to avoid snagging on furniture and backpacks; use label windows for room numbers and AV points. Retail and public buildings: favor reinforced IK faces and tamper-proof caps on screws. Healthcare: smooth faces, sealed LEDs, and consistent legend schemes. Where mirror lines are tight, slim bezels keep clearance near cabinetry and glass. For visible hospitality clusters, siemens decorative frames coordinate palette without re-engineering the box plan.

Integration with Siemens wiring devices and boards

Frames accept the same insert family used on siemens switches and sockets pages—rockers, dimmers, USB chargers, RJ45/data, and keystone blanks sit in one grid. Divider trunking behind plates segregates SELV (1–10 V/DALI) from mains. When specifications call for splash protection, pair frames with the correct collars and siemens switch socket covers so IP claims survive after service. In plant rooms and podium levels, publish one legend scheme; the same fonts should appear on plates, panel labels, and HMIs for maintenance clarity.

Other Siemens products:

Selection criteria for B2B clients

- Grid and gang plan: fix 2-way + intermediate logic early; it drives box count and frame widths.

- Finish vs environment: thermoset for heat and dimmer clusters; ABS or metal-front for impact; sealed kits where detergents or spray are credible.

- Depth reality: confirm box depth and conductor volume; specify short-body adapters for 35 mm recesses.

- Thermal spacing: use spacers between electronic modules; document minimum dimmer set-point in handover notes.

- Identification: engrave or use snap-in windows—avoid stickers in solvent-cleaned buildings.

- Standardization: lock one frame family campus-wide; order spares per frame size and finish to keep van stock lean.

For heavy retrofit schedules, pre-bag room kits that include frames, shims, spacers, gaskets, screws, and label windows—those are your practical siemens mounting frames bundles.

Cross-category integration for complete rooms

Tie plate choices to device schedules: if the project uses siemens modular frames, ensure data apertures and USB chargers share the same bezel language; if surge-protected outlets appear in meeting rooms, keep the finish consistent on adjacent AV plates. Where boards list RCD-protected circuits feeding desk runs, note IP kits for janitorial areas. For hospitality headboards, coordinate dimmer heat load with plate material and include matching siemens switch socket covers for housekeeping durability.

Advantages of working with Bankoflamps

We align frame families, finishes, and IP kits to your room schedule and elevations, then confirm live EU stock before installers are booked. Quotations usually land in about an hour with EAN/MPN so aperture count, finish, and accessory packs don’t drift between phases. Your portal shows lead times, shipment status, and downloadable price lists; pricing validity is kept stable to match approval gates. Approved accounts can use post-payment up to 30 days. We consolidate by room or floor to cut freight and on-site sorting, and your account manager cross-checks box depth, gasket compression, engraving plan, locator-LED voltage, and adapter selection against your drawings—so cartons arrive site-ready and crews fit once.