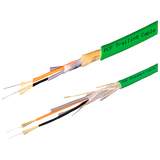

Siemens Fibre optic cables

siemens fibre optic cables Application scope and brand context

Industrial plants, transport hubs, and data rooms move fast only when the backbone is predictable. Siemens specifies fibers and jackets that survive trays, robot cells, and control rooms without surprise losses. Core geometries follow 9/125 and 50/125 or 62.5/125 µm, with indoor LSZH CPR-rated sheaths for buildings and PE armoured runs for yards. Published pull, crush, and bend limits mean your route plan turns into a clean as-built, not a splice marathon.

siemens optical network cables Product range and construction

Portfolios cover tight-buffered riser cables for cabinets, gel-filled loose-tube for campus links, and steel-tape or dielectric FRP armoured variants where forklifts and rodents are a risk. Counts from 2 to 24 cores are common indoors, rising to 48/96/144 in ducts. Factory pre-terminated trunks (LC/SC and MPO) cut install hours in racks; pigtails and splice cassettes match the same ferrule standards to keep return loss consistent. Temperature windows typically −20…+60 °C operating; tensile ratings and crush figures are printed by type so installers can set winches and rollers correctly.

Other Siemens products:

siemens singlemode fibre cables Optical performance and reach

OS2 low-water-peak cores to ITU-T G.652.D or bend-optimised G.657.A1/A2 extend 1–10 G over kilometres and carry 40/100 G with DWDM where required. Attenuation targets sit around 0.34 dB/km at 1310 nm and 0.22 dB/km at 1550 nm; macrobend-safe designs hold loss down in tight trays. APC connectors are available for sensitive OTDR budgets; UPC fits typical switch optics without stray reflections.

siemens multimode fibre cables Campus and factory backbones

OM3/OM4/OM5 options cover 10 G to 100 G short-reach inside buildings. Embodied bandwidths land near 2000 MHz·km (OM3) and 4700 MHz·km (OM4) at 850 nm, with wideband OM5 easing SWDM upgrades. For brownfield risers still using 62.5/125 equipment, matching cords protect legacy links while you phase to 50/125 electronics.

Technical specifications and standards

Cables conform to IEC 60793/60794 for fiber and construction; systems map to ISO/IEC 11801 and TIA-568.3-D for structured cabling. Reaction-to-fire per EN 50575 CPR is available from Eca up to Cca-s1,d1,a1 on indoor sheaths; smoke-limited LSZH jackets are standard for occupied spaces. Minimum bend radii follow 10× OD dynamic and 7.5× OD static on bend-insensitive types. Connector families meet IEC 61754; insertion loss is typically ≤0.3 dB (LC/SC) and ≤0.35 dB per MPO leg when factory-polished. Polarity and pinout documentation ships with pre-terms so field tests pass first time.

Applications and compatibility

Process areas use fiber to dodge EMC from drives and welders; ring or MRP topologies with <200 ms healing keep HMI and safety links alive during maintenance. In rail and road cabinets, IP-rated breakout boxes with gland plates let you park slack safely. Camera networks prefer pre-terminated MPO trunks to speed bay wiring, then fan out to LC at the switch. Where drawings call up siemens fiber optic wires, confirm core count, jacket class, and connector polish so procurement doesn’t mix UPC and APC across a span. For IT rooms moving large historian datasets, specify siemens data fiber cables with OM4/OM5 trunks to hold 10/25/40 G headroom over existing pathways. Utility yards and tunnels benefit from traceable orange sheaths and armored construction on siemens optical communication lines to survive accidental digs.

Integration with other Siemens products

SCALANCE X switches, XC/XR modular chassis, and SFP optics slot straight onto LC or MPO panels; managed features (RSTP/MRP, VLANs, ACLs) play well with these links. PROFINET and Industrial Ethernet over fiber isolate noisy motor rooms from controllers; SINEMA Server takes the SNMP view of optics, temperature, and error counters so you catch degradation before alarms fire. For SIMATIC cells, media converters and redundant ring modules live in the same footprint as SENTRON protection and Siemens gland systems, which keeps EMC and IP ratings intact through the enclosure wall.

Selection criteria for B2B clients

Start with reach and protocol: OS2 for long-haul plant interconnects, OM4/OM5 for dense 10–100 G inside buildings. Fix core count by present ports plus 30–50 % spare for growth and OTDR. Choose sheath and CPR by route: LSZH Cca for escape routes, PE or UV-stabilised for outdoors, armouring where trays are exposed. Verify connector type and polish against optics—LC-UPC is the default; reserve APC for PON or high-reflection-sensitive spans. Check mechanicals: tensile rating for the longest pull, crush for shared trays, and bend rules around door pillars and cable management. In cabinets with tight radii, specify G.657.A2 to keep macrobend loss off your budget. Document polarity early on MPO trunks to avoid field re-pinning.

Advantages of working with Bankoflamps

We align fiber type, CPR class, core count, and connector sets to your network drawings, then expose live EU stock by warehouse before night shifts are booked. Quotes land in roughly one hour with EAN/MPN, attenuation/bandwidth, bend and pull limits, and connector polish codes, so nothing drifts between design and install. Your portal shows lead times, order status, and downloadable price lists with validity dates; approved accounts can use post-payment up to 30 days. We consolidate by rack row, building riser, or route segment to cut freight and site sorting. Your account manager cross-checks SFP types, ring topology, gland threads, spare cores, and CPR documentation against the pack list—so reels and pre-terms arrive rack-ready and crews certify once.