Siemens Circuit Breakers

Miniature circuit breaker 1P B10

siemens breakers for LV boards

Thermal-magnetic ranges cover 230/400 V AC (50/60 Hz) and DC rails with breaking capacities sized to real fault levels: 6 kA for light commercial, 10–15 kA where service capacities run higher, and industrial lines under IEC/EN 60947-2 for large boards. Trip curves include B/C/D (typ. 3–5/5–10/10–20 × In), plus K/Z where inrush or long cable runs demand different magnetics. Isolation function is marked on the front; I²t let-through and energy limitation classes are published for cable and busbar checks. Ambient derating tables (e.g., 40 °C boards or altitude) are provided—use them when cramming rows beside drives or UPS.

siemens din rail devices portfolio and footprints

All devices land on 35 mm rail with identical pitch, front test points, and multi-function windows. Frames span 1P, 1P+N, 2P, 3P, and 3P+N; terminals accept 1.5…35 mm² (device dependent) with comb busbar grooves and separate cage for auxiliaries. Accessory stack: OF/SD aux contacts, shunt trip, undervoltage release, lockout hasp, and pin/fork busbars with feed-in blocks. Labels print clearly on the escutcheon; QR codes pull the exact curve sheet on a phone during FAT.

Other Siemens products

siemens miniature circuit breakers characteristics

Standards compliance is straight: IEC/EN 60898-1 for typical building boards and IEC/EN 60947-2 for industrial high-breaking SKUs. Rated voltage 230/400 V AC; DC versions list per-pole limits and series wiring diagrams. Endurance runs 10k–20k mechanical ops; electrical life follows curve and duty. Terminal cages publish torque (e.g., 2.0–2.5 Nm on 6–25 mm²); twin terminals on selected frames permit loop-through without bodging ferrules. For nuisance trips on LED drivers, pick C or D magnetics and document inrush on the circuit schedule.

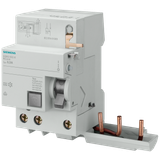

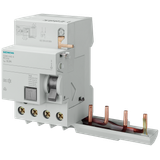

siemens residual current breakers types and selection

RCCBs/RCBOs arrive in Type AC (legacy), Type A (pulsating DC), Type F (mixed-frequency drives/heat pumps), and Type B (smooth DC—EV/PV/UPS). Sensitivities 10/30/100/300/500 mA; time-delay S for selectivity; IΔc immunity ratings to ride through surge. RCBOs combine overcurrent + residual in one pole space: faster fault-finding and tighter discrimination on small boards. Standards: IEC/EN 61008-1 (RCCB), IEC/EN 61009-1 (RCBO), with Type F/B referencing IEC 62423. For EVSE, pair DC-monitoring (RDC-DD) policy with the chosen type—don’t stack protections blindly.

siemens mcb protection coordination and wiring

Cascading/back-up tables show how upstream MCCBs or fuses raise downstream breaking capacity and preserve selectivity. Publish the fault level at each panel, then pick the downstream curve so discrimination survives real Ik, not the utility max. Use phase barriers near incomers; keep comb busbars within manufacturer ratings; and respect terminal class—solid vs fine-strand with ferrules. Where DC strings exist (PV, battery), use marked poles and observe the stated polarity and series wiring for arc interruption.

siemens modular electrical devices beyond protection

Rail lines include AFDDs (arc-fault detection) for high-risk accommodation, SPDs to IEC 61643-11 (Type 1/2/3 with Up/In stated), motor-protective breakers with adjustable Ir and phase-loss trip, contactor auxiliaries, timers, meters (V/I/PF/THD), and networked meters on Modbus/PROFINET. Voltage monitoring relays catch brownouts; load-shedding relays manage generator changeover. These share the same busbar geometry and accessory set, so panel doors don’t fill with orphan parts.

siemens circuit protection units integration and application

Apartments and hotels: B-curve 6–10 kA with 30 mA Type A RCBOs per room; AFDD where code or insurer demands. Offices and classrooms: C-curve with SPDs at the board, Type A/F on IT/HP circuits; RCBO maximizes uptime. Retail/back-of-house: D-curve for refrigeration inrush; delayed RCCB on submains to maintain selectivity. Industrial cells: 60947-2 frames, Type B on VFD/UPS/EV, coordinated SPDs (Type 1+2 at main, Type 2 at subs). PV and storage: gPV DC fusing upstream, Type B residual on the AC coupling, DC-rated MCBs where used.

Practical engineering notes

- Record Ik at every board; then prove selectivity with vendor tables.

- Group heat sources—AFDD, RCBO, USB PSU—away from each other or leave a blank to control face temperature.

- Use pin busbars for dense rows; fork bars where mixed frames appear.

- Document terminal torque in the method statement; most hot spots trace to under-tightening.

- For maintenance, specify trip-flag windows and OF/SD contacts on critical feeders; SCADA then pinpoints the trip.

Applications, sizing, and standards in one place

- Ratings: 6/10/15 kA Icn; 230/400 V AC; DC ratings per pole.

- Curves: B/C/D/K/Z; adjust for LED/VFD inrush and cable Zs.

- RCD: Type A/F/B; IΔn 10–500 mA; S-delay where required.

- SPD: Type 1/2/3; Up/In; coordinated at main and sub boards.

- Compliance: IEC/EN 60898-1, 60947-2, 61008-1, 61009-1, 62423, 61643-11, 61439 (assembly heat rise).

Integration with adjacent Siemens ranges

Upstream MCCBs and meters live in the same ecosystem; accessory coding prevents wrong fits. HMIs and gateways collect OF/SD status; power meters expose load so you can right-size breakers instead of over-specifying. Comb busbars match rail pitch in distribution boards; terminal markers align with the brand’s legend system for panels and wall plates. For EV/PV, coordinate Type B residuals with charger/inverter internal detection to avoid stacked trips.

Selection checklist for B2B teams

- Fault level by board and desired discrimination path.

- Load type and inrush (LED, VFD, compressors).

- Residual type (A/F/B) by appliance class and code.

- SPD level by surge environment and insulation category.

- Ambient and enclosure size—apply derating, de-cluster heat.

- Serviceability—RCBOs for faster resets; trip signaling on criticals.

- Documentation—curve sheets, torque, and busbar maps in the FAT pack.

Advantages of working with Bankoflamps

We align frames, curves, residual types, and SPD levels to your one-line and Ik study, then show live EU stock before outages are locked. Quotes usually return in about an hour with EAN/MPN so breaking capacity, trip curve, pole count, and accessory kits don’t drift mid-phase. Your portal lists lead times, shipment status, and downloadable price files; pricing validity tracks approval gates. Approved accounts can use post-payment up to 30 days. We consolidate by board section to cut freight and bench time, and your account manager cross-checks Ik, selectivity charts, RCD type, SPD coordination, terminal size/torque, busbar pitch, and labeling against your drawings—so trays land board-ready and electricians fit once.