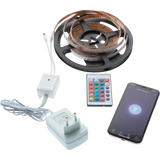

Shada Light ribbon-/hose/-strip

Shada Light ribbon-/hose/-strip: a fast decision map before you pick anything

Use this logic first, because it prevents 80% of wrong purchases:

- If the light line is directly visible (eye-level lines, feature outlines, signage-style effects) → choose a diffused “neon-style” strip for a continuous look.

- If the light source is hidden (coves, behind lips, inside aluminum profiles) → choose ribbon/LED tape for the cleanest integration.

- If the run will be exposed to knocks, movement, or rough handling (temporary installs, outdoor outlines, handrails) → consider hose/rope or neon-style jacketed formats for mechanical protection.

Shada Light ribbon-/hose/-strip: what “good-looking” actually depends on

The final appearance is driven by geometry and diffusion, not by wattage alone:

- Depth to diffuser: deeper channels smooth the line and hide dots.

- LED pitch/density: tighter spacing reduces “pearls” on the diffuser.

- Diffuser material: opal hides points; clear looks punchier but reveals emitters.

- Viewing angle control: if people see the strip from the side, prioritize diffusion and lower high-angle brightness.

A practical rule: if you can’t add depth, upgrade diffusion (neon-style) instead of just increasing power. Light ribbon, hose and strip solutions are widely used in projects where flexible routing, continuous light lines and precise control over accent lighting are required. In architectural interiors, retail environments and custom fit-outs that demand clean linear illumination with refined detailing, designers often start with design-driven options such as slv light ribbon hose strip, selected for accurate light distribution and integration into architectural profiles. For technical installations and electrically regulated environments where system compatibility and reliable connection standards are essential, planners frequently rely on structured solutions like schrack light ribbon hose strip, supporting predictable installation within professional electrical frameworks. In cost-efficient projects and routine decorative applications that require straightforward handling and functional linear lighting, installers often choose practical ranges such as ret light ribbon hose strip, suitable for outlining features and basic ambient layers. Where stable luminous performance and consistent behaviour over extended operating hours are required, specifiers commonly turn to proven solutions like radium light ribbon hose strip, ensuring dependable output across various installation scenarios. And when projects require globally standardised LED strip and hose solutions with long-term availability, broad compatibility and recognised performance benchmarks, planners typically complete their specification with internationally established systems such as philips light ribbon hose strip.

Shada Light ribbon-/hose/-strip: electrical planning that keeps brightness even

Uneven brightness usually comes from voltage drop and poor feeding, not from “bad LEDs.”

- Prefer 24 V for longer runs when you want consistent brightness across the full length.

- Avoid one-end feeding on long lines; plan mid-feed or power injection points where needed.

- Driver headroom: size drivers so they run comfortably below maximum load for better stability and lifetime.

- Cable choice matters: long low-voltage runs need sensible cable sizing to prevent dim tails.

If your design needs one uninterrupted long line, plan the feed strategy before you finalize lengths and cut points.

Shada Light ribbon-/hose/-strip: dimming and control choices by real user behavior

Pick controls based on how the space is operated (not what’s trendy):

- Simple dimming: best for mood tuning in hospitality, bedrooms, reception areas.

- Scenes: ideal when the same line needs “day / evening / cleaning” modes.

- RGB / RGBW: only when color has a defined purpose (brand identity, events, wayfinding).

- Camera-heavy zones: prioritize stable, comfortable dimming behavior to avoid visible banding or unpleasant shimmer on video.

Good specs describe who controls it (staff, guests, automation) and how often it changes.

Shada Light ribbon-/hose/-strip: environment risk grading (and how to avoid early failures)

Think in exposure levels instead of room names:

- Protected indoor: ribbon strip in aluminum profile is usually the cleanest and easiest to service.

- Condensation / splashes: use sealed options and treat every connector and cut end as a sealing task, not an accessory.

- Outdoor UV + water + movement: jacketed neon-style or hose solutions, secured with proper clips and strain relief.

Most “waterproof” failures happen at ends, joins, and cable entries, not along the middle of the strip.

Shada Light ribbon-/hose/-strip: installer habits that separate pro results from call-backs

- Heat management first: higher-output ribbon strips need aluminum for cooling.

- Mounting discipline: don’t rely on adhesive alone where heat, dust, or textured surfaces exist—use profiles/clips.

- Bend radius respect: tight corners kink neon-style jackets and cause uneven output.

- Strain relief: protect every connection so movement doesn’t rip pads or loosen joins.

- Two-stage testing: test on the bench, then test again after mounting before sealing and closing profiles.

Shada Light ribbon-/hose/-strip: a procurement pack that prevents missing parts

Order it like a system, not like a roll:

- Chosen format: ribbon vs hose vs neon-style

- Voltage + total run lengths + planned feed points

- W/m + driver sizing (with headroom)

- White tone or RGB/RGBW strategy (keep it consistent across the project)

- Mounting method: profile depth, diffuser type, corner approach

- Connector method: solder vs plug + any sealing/end-cap materials

- Spare plan: one compatible driver/controller and a short matching section for rapid fixes