Schneider Electric Mounting materials

Schneider mounting materials for panels and machines

Built for panel shops and OEMs that care about repeatable geometry and service access, this hardware covers rails, plates, brackets, profile fittings, strain bars, and fasteners that hold layout tolerances over years of vibration and thermal cycling. Parts ship in zinc-nickel plated steel for factory floors, anodized aluminum where mass matters, and A2/A4 stainless for wash-down. Hole patterns follow 25 mm grids with M5/M6 threads; slotted faces absorb ±3…5 mm during alignment. Edges are deburred to protect cable jackets and gloves. Torque cards accompany kits so installers hit pull-out and anti-vibration requirements on first fit.

Product range and series overview

- DIN rails and plates: EN 50022 35 mm rail in solid/perforated forms, copper-bonded where PE continuity through paint is required; baseplates and door plates sized to common enclosure frames.

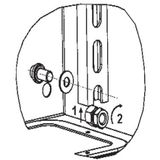

- Sensor and interlock carriers: L-, T-, and U-brackets with long slots for fine positioning of reed, inductive, and coded guard actuators; hinge/striker adapters for rotating doors; offset shims to keep actuator parallelism on welded frames.

- Profile hardware: T-nuts (spring-ball and serrated), corner brackets, stand-offs, and vibration pads for 30×30 and 40×40 aluminum profiles.

- Cable management supports: strain-relief bars, tie bases, and saddle clamps that keep terminals stress-free during door swing and maintenance.

- Door-coupled drive parts: shafts, bearings, and carriers that align switch disconnectors and selector switches through the door skin without side-loading devices.

Technical specifications and standards

Mechanical design references IEC 60204-1 for equipment mounting and protective bonding points, ISO 14119 for interlock/actuator positioning, and IEC 60068-2-6/-2-27 for vibration/shock where specified. Plated steel hardware meets neutral salt-spray classes typical of production halls; stainless items use AISI 304/316 with rounded radii for hygienic zones. Typical operating window −25…+70 °C. Thread engagement tables accompany kits (e.g., M6 8.8 bolts at 9–10 N·m into steel; reduced torque for aluminum with thread-formers). Paint-safe standoffs preserve conductive paths for PE jumpers when bonding is required.

Schneider brackets and fixtures for sensors and guards

Guard sensing is geometry-critical. Adjustable carriers provide slot travel to set switching distance and hysteresis within the sensor’s permissible misalignment. Color-coded shims help technicians restore the specified actuator gap after service. Stainless carriers use polished faces to shed residue in CIP areas; serrated washers and double-nutting on studs hold position on high-vibration presses. For long doors, dual shaft bearings remove bending from device bodies and keep operator handles free-running.

Applications and compatibility

Packaging cells mount coded actuators on polycarbonate guards with slotted brackets; press lines use rigid carriers and vibration pads; robot cells rely on profile hardware to shift brackets during tool changes. Strain bars and tie bases sit behind gland plates so terminals never carry cable weight. All items match the geometry of Schneider devices—TeSys contactors, Harmony operators, Acti9 modulars, and guard switches—so hole centers, shaft heights, and label windows repeat cabinet to cabinet. That consistency shortens commissioning and prevents drawing edits during late changes.

System architecture and panel coordination

Keep a fixed coordinate grid on mounting plates to standardize bracket positions across model years. Reserve cold duct for low-level I/O; route VFD feeders away from safety wiring and bond EMC clamps near entry to minimize shield pigtails. Set door hardware on a common centerline and support the shaft near the hinge to curb deflection. Use relief bars on each moving panel; clamp spacing is documented so crews can rebuild a cabinet after retrofit without re-measuring.

Integration with other brand products

Brackets and carriers align with Schneider safety relays, coded sensors, interlocks, light curtains, and switch disconnectors. Shunt-trip and undervoltage coils on feeders benefit from predictable strain-bar locations; Harmony operators share the same carrier cutouts; Altivar drive kits land on the profile hardware without drilling new holes. The result is one mechanical language across detection, logic, and power.

Selection criteria for B2B engineers

Start with the environment, then define the device family and the needed slot travel.

- Material and coating: stainless for wash-down; zinc-nickel steel for dry plant; anodized aluminum where mass and access dominate.

- Geometry: confirm switching distance and misalignment from the chosen sensor/interlock; pick a bracket with enough slot length and shim range to hit those numbers.

- Fastening: match thread class to substrate; use through-bolts or steel inserts on aluminum profiles to avoid creep.

- Serviceability: prefer captive hardware, printed torque values, and dowel-pin holes to lock the final position after commissioning.

This is where schneider installation hardware keeps outcomes predictable—identical head styles and washer stacks reduce tool changes and assembly variance.

Procurement and kitting for OEM programs

Standardize a short kit per frame size: rail length, plate, two bracket types, stand-offs, strain bar, fasteners, and a torque/position card linked to CAD article numbers. Kitting by station (cabinet, machine left/right, robot cell) cuts picking time and ensures FAT and field work see the same parts. Stock color-coded shims and spare shaft bearings; service teams can restore actuator geometry in minutes instead of re-aligning from scratch.

Advantages of working with Bankoflamps

You receive project-specific pricing tied to your BOM, real-time stock across EU warehouses, and a named account manager. Quote requests are typically answered in about an hour. Orders by EAN/MPN prevent variant drift; the portal shows lead times, shipment status, and downloadable price lists for planning. Approved customers can use post-payment up to 30 days. We consolidate partials to reduce freight and maintain price-validity windows so phased builds stay predictable. Our engineers cross-check bracket coordinates, shaft kits, and fastener stacks against your drawings so cartons arrive rail-ready and complete.