Schmersal Control devices, buttons

schmersal control devices buttons built for panels that run every shift

Machine builders choose this range when operators need clear feedback, safe stops, and hardware that holds torque after thousands of cycles. The platform centres on 22 mm and 30 mm mounting geometries with modular contact blocks, LED modules in 12/24 V DC and 110/230 V AC, and bezels in metal or reinforced polymer. Typical duty ratings: AC-15 6 A @ 230 V, DC-13 2–3 A @ 24 V; mechanical endurance commonly ≥ 1,000,000 actuations on momentary types. Fronts seal to IP65–IP67; impact resistance to around IK07–IK08 keeps heads intact in busy cells.

Range overview of schmersal operator devices

Actuators cover mushroom, flush, and extended heads; selector switches with maintained or spring-return positions; key-release for mode control; and illuminated pushers for status or reset. Contact blocks stack 1–6 poles with snap-on latches and clear NO/NC marking; late-break/early-make options support control interlocks. LED modules use quick-connect blades; colour coding follows IEC 60204-1 (red stop, green start, blue mandatory, yellow abnormal). Accessories include legend plates, anti-rotation rings, protective shrouds, and stainless fixings for wash-down lines.

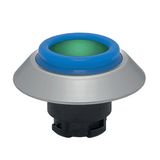

schmersal push buttons — actuators, lenses, and feedback

Heads are available in low-profile and glove-friendly domes; lenses in clear, opal, or colour-saturated types; and bodies with metallic knurl for grip when oily. Brightness-stable LEDs keep status readable under high ambient light. Audible click or increased force curves can be specified for tactile confirmation through gloves.

schmersal emergency stop buttons — functional safety and reset logic

Mushroom heads Ø 30–40 mm with latching per ISO 13850; twist-release or key-release variants prevent inadvertent resets. Positive-opening NC contacts per IEC 60947-5-1/-5 ensure contact separation even if welded. Optional protective collars reduce accidental hits; illuminated rings assist location in low light. Typical reaction times through safety relays: 8–20 ms.

schmersal safety switches — guard and interlock interfacing

Tongue, hinge, and RFID-coded door switches integrate cleanly with the push-button family for start/acknowledge/reset stations. High-coding levels support ISO 14119; OSSD or dry-contact outputs connect to safety controllers with EDM and cross-short detection. Stainless housings and IP67/IP69K options handle CIP wash areas.

schmersal control panels — ready layouts and enclosure options

Pre-punched plates and shallow enclosures speed assembly: 3–12 device apertures with 40/60 mm grid spacing, internal DIN rail for terminals, and M20/M25 gland plates. Windowed doors keep legends protected; emergency-stop stations are supplied as single-function pods for fence posts and conveyors.

Technical specifications and standards engineers expect

- Electrical: AC-15 and DC-13 ratings on contact blocks; gold-flash versions for PLC-level currents; terminal capacity 0.5–2.5 mm²; captive screws or spring clamp.

- Ingress/impact: IP65–IP67 fronts; IK07–IK08 housings; UV-stable plastics for outdoor HMIs.

- Environment: −25…+70 °C operating, condensation-resistant gaskets; chemical-resistant heads for cutting fluids.

- Compliance: IEC/EN 60947-5-1 (control devices), IEC/EN 60947-5-5 & ISO 13850 (E-stop), ISO 14119 (interlocking), IEC 60204-1 (machine wiring), EN 61000-6-2/-4 (EMC).

- Identification: laser-etched legends, replaceable tags; colours per IEC/ISO conventions to avoid operator error.

Applications and compatibility across machinery

Assembly cells: start/stop, mode select, and illuminated reset at each station; guarded resets wired through safety logic. Packaging lines: wash-down heads, raised collars, and stainless fixings near conveyors. Metalworking: key-select for setup/automatic modes; robust E-stop pods on press frames. In retrofit work, adapters let 22 mm devices drop into older 30 mm cut-outs without re-punching—the wiring stays on standard ferrules.

Integration with safety and automation stacks

Push-button stations wire directly to Schmersal safety controllers and distributed I/O; auxiliary contacts feed PLC diagnostics for “request to start” and “acknowledge” sequences. Contact blocks share depth envelopes with common cabinet door furniture; gland threads and rail pitch match your existing enclosures and distribution hardware, so spares and tools remain unified.

Selection criteria for B2B clients

- Operator intent: pick momentary vs maintained; add tactile/audible feedback where gloves are used.

- Safety policy: choose E-stop reset style (twist/key) per risk assessment; specify positive-opening NC contacts and EDM in the circuit.

- Environment: confirm IP/IK class; use stainless heads and sealed legends in wash-down or outdoor zones.

- Electrical interface: match AC-15/DC-13 ratings to coil/PLC loads; use gold-flash for < 10 mA logic.

- Ergonomics & visibility: size heads and lens colours to the viewing distance; add illuminated rings for low-light bays.

- Panel efficiency: standardise on 22 mm across the plant; pre-kit legend sets and gland sizes to speed night-shift swaps.

Advantages of working with Bankoflamps

You receive individual B2B prices tailored to your panel schedule and a personal account manager who stays with the job. Stock availability is shown in real time across our and partner warehouses. Send a quote request online and expect a quick reply—usually within 1 hour. Fast order placement by EAN/MPN keeps your ERP clean, and you can download up-to-date price lists anytime. The portal provides lead-time tracking and order-status visibility, plus purchase-history access for SKU rationalisation. For trusted clients we support post-payment up to 30 days. Consolidated order management groups ready lines to cut freight, with smart delivery cost estimates at order and exact figures before dispatch. Prices carry validity dates so phased works remain predictable.