Scame Lighting accessories

scame lighting accessories for installation, service, and upgrades

Specifiers use this family to keep luminaires consistent across floors, speed second-fix, and make future swaps painless. The parts cover mounting, optics, wiring, and small hardware that determine whether a fitting sits flush, keeps its IP rating, and delivers the beam the plan expects. Sizes align with common backplates and 60 mm fixing centres; plastics are halogen-free where projects demand it, and metal parts are finished for real site conditions (painted, zinc, or stainless).

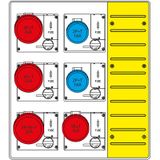

Range and series overview

You’ll find three practical buckets.

Mounting and trim pieces handle ceiling/wall transitions, conduit stand-off, and anti-tamper needs. Optical components manage glare and distribution from stair cores to reception counters. Wiring and small-parts kits—glands, through-wire links, quick-couplers, label windows—keep install time predictable and maintenance tidy. Emergency variants add test buttons, legends, and brackets that don’t compromise the enclosure seal.

scame mounts and trims for clean alignment and IP retention

Spacer rings and leveling plates correct uneven plaster or tile so frames read straight down a corridor. Surface conduit adapters bring entries to the rear or side without ad-hoc drilling. Anti-tamper bezels and security screws protect school and transport zones. Where luminaires must sit low-profile, slim trims keep projection to 80–95 mm while preserving access to terminal covers and gaskets.

scame connectors and adapters for quick wiring changes

Push-in and screw-cage blocks accept 1.5–2.5 mm² loop-through on mains variants; coded plugs support tool-free gear-tray swaps during night works. DALI/0–10 V pigtails are colour-keyed; through-wiring kits maintain conductor segregation and earth continuity across linear runs. For damp rooms, matched glands and seals avoid mixing brands and losing IP.

Technical specifications and standards

Electrical and optical: accessories are sized for drivers with PF ≥ 0.90 and THD < 15–20 % on mains luminaires; optical elements use PC or PMMA with ≤ 3 SDCM colour uniformity targets maintained. Photobiological safety of diffusers and shields aligns with EN 62471 (RG0/RG1 typical).

Ingress/impact: maintained ratings up to IP65 with correctly fitted gaskets and glands; impact resistance to IK08–IK10 for vandal-prone areas per EN 62262.

Materials: UV-stabilised polycarbonate for outdoor edges; die-cast or pressed metal for high-abuse rings; stainless A2/A4 in wash-down and coastal zones. Finishes resist common cleaning agents.

Interfaces: hole patterns match 60 mm centres and standard 68 mm cut-outs; gland entries M16/M20 with stated clamping ranges.

Compliance pointers: luminaires to EN/IEC 60598-1 and relevant -2 parts; ingress per EN/IEC 60529; small wiring parts to EN 60998/60947-7 as applicable. Where glare control is a priority, call up scame lens covers (opal, micro-prismatic, or asymmetric) to hit UGR and uniformity targets without changing the base fitting.

Applications and compatibility

Corridors and stair cores use glare-controlled optics and spacer rings to hide substrate drift. Wash-adjacent areas fit gasketed trims and sealed glands to hold IP54–IP65. Front-of-house gets thin bezels and softer optics; plant rooms prioritise anti-tamper and robust entries. Mechanical geometry aligns with Scame wall and ceiling luminaires, installation boxes, and distribution boards, so the same tools, labels, and torque values apply. In spares lists, facilities teams group small kits under scame lighting hardware to keep ordering clean across sites.

Integration with other brand products

Backplates and gland threads match Scame installation boxes; earth studs and screw sizes mirror those on Scame enclosures and panel boards. Quick-couplers and link leads share colour coding with Scame control gear, so DALI loops and emergency test circuits are easy to trace. For temporary works, accessories pair with Scame plugs and distributors to power test modes without disturbing permanent cabling.

Selection criteria for B2B clients

Mounting and substrate: confirm ceiling type (plasterboard, slab, tile) and choose spacer rings or stand-offs that keep bezels flat and sightlines straight.

IP/IK envelope: pick sealing kits and security trims to reach the required IP/IK without over-tightening—gasket compression should sit mid-band for re-torque after inspection.

Optics and glare: select opal for soft ambient, micro-prism for corridors, asymmetric where wall-wash or wayfinding is needed; verify UGR vs mounting height.

Wiring method: standardise on push-in vs screw terminals by contractor preference; ensure through-wire kits match conductor class and loop currents.

Materials and finish: use stainless or coated metal in wash-down/coastal zones; specify halogen-free plastics for low-smoke projects.

Logistics: pre-kit room types with trims, optics, and glands; hold a labelled bin of scame spare lighting parts—gaskets, clips, windows—to cut downtime during call-outs.

Advantages of working with Bankoflamps

You get Individual B2B Prices tailored to your room and fixture schedule, plus a Personal Account Manager who stays with the job. Stock availability is live across our and partner warehouses. Submit a Request a quote online and expect a fast reply—usually within 1 hour. Fast Order Placement by EAN/MPN keeps your ERP clean, and you can Download Price Lists any time for current revisions. Track builds with Lead Time Tracking and use Purchase History Access to standardise trim and optic sets across sites. Eligible clients can access Post-Payment for Trusted Clients up to 30 days. Use Consolidated Order Management to group ready lines and cut freight, with Smart Delivery Cost Estimates shown at order and confirmed before dispatch. We keep Stable Prices With Validity Dates so phased rollouts remain predictable.