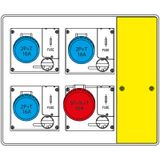

Scame Electric box (breaker panel)

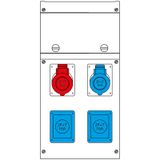

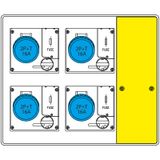

DISTRIBUTION ASSEMBLY

DISTRIBUTION ASSEMBLY

CONNECTION KIT PG36 GREY

scame distribution boards project context

Site teams use this hardware to keep protection selective, labels legible, and maintenance fast. The platform spans flush and surface assemblies for rooms and risers, plus steel-bodied gear for plant areas. Current envelopes typically run 63–250 A incomers on modular boards and up to 630 A on cabinet systems. Protection devices land on 18 mm pitch with tidy wiring space, so ferrules seat cleanly and heat stays under control during summer loads.

Scame product range and series overview

Residential and light-commercial floors lean on compact boards for lighting and socket circuits, with transparent or solid doors and hinge directions that match corridor swing. Office cores and kitchens step up to higher Icn ratings and split-load layouts for RCD selectivity. Production areas rely on metal sheet enclosures with segregated busbars, cableways, and gland plates that take real glands—not just caps. For temporary or remote corners, small weatherproof boxes pick up tap-offs without breaking the visual language used elsewhere. Within this mix sit the scame panel boards that planners specify when uniform device spacing, clear marking strips, and spare ways are a must.

scame modular enclosures formats and accessories

Empty thermoplastic and metal boxes accept DIN rail, PE/N bars, and door kits. Widths cover 8 to 72 modules per row, 1–4 rows, with add-on cable entry plates in M20 to M40. Knockouts line up to conduits on 60 mm centers; depth options give room behind RCBO tails and AFDDs. Accessories include meter windows, phase barriers, gland flanges, and blanking modules for future ways.

scame switchgear cabinets capacities and layouts

Floor-standing or wall-mounted cabinets carry main switches, MCCBs, metering, surge devices, and outgoing MCB rows. Busbars sit at 160–630 A with form-of-separation options for safer live-side work. Hinged inner doors keep fingers clear of live parts during inspection. Cable drops are left or right with removable gland plates; rear clearance supports bottom or top entry without tight bends.

Technical specifications and standards

Electrical Incomers 63–250 A on modular assemblies; cabinet busbars up to 630 A. Short-circuit withstand sized to supply fault level, typically 6–10 kA Icn on MCB rows and 25–50 kA Icu on MCCB incomers when backed by upstream limitation. Device families cover MCBs to EN/IEC 60898-1, RCBO/RCCB to EN/IEC 61009/61008, MCCB to EN/IEC 60947-2, SPDs to EN/IEC 61643-11. Boards and cabinets align to EN/IEC 61439 series; empty boxes to EN/IEC 62208.

Ingress and impact IP30–IP41 for clean interiors; IP54–IP65 with gasketed doors for plant rooms and wash-down zones; impact resistance up to IK08 per EN 62262 where trolleys pass.

Thermal envelope −5…+40 °C typical; apply derating for high ambient, grouping, and continuous RCBO banks. Ventilation slots and cableways keep device temps within manufacturer limits.

Wiring and terminations Copper bars with captive nuts; PE/N bars sized for parallel earth and neutral returns. Cable space supports 1.5–50 mm² conductors; torque values printed near terminals.

Integration Details 18 mm pitch across rows, removable DIN sections, and numbered rail positions simplify testing and O&M documentation.

Applications and compatibility

Office floors carry lighting, socket, and small mechanical circuits with split-RCD or all-RCBO strategies. Hospitality and retail add time clocks, EV spur feeds, and refrigeration circuits. Light-industrial sites use metal cabinets, higher Icu, and surge protection at board level. Mechanically, the enclosure geometry matches Scame wiring devices, installation boxes, and industrial outlets, so glands, screws, and label sets stay consistent. Pop-up kitchens or stages often hang compact weatherproof boxes as scame electrical distribution units to feed strings of 16 A and 32 A sockets on short runs.

Integration with other brand products

Boards align with Scame isolators for local lock-off, plugs and distributors for downstream connections, and EV hardware where a dedicated breaker and SPD pair is required. Gland threads, door hardware, and labeling kits share parts across families, which helps maintenance teams carry one spare set for mixed areas. Indicator windows and auxiliary contacts provide clean dry-contact points for BMS alarms and energy meters.

Selection criteria for B2B clients

Protection and selectivity Map fault level, feeder size, and discrimination with upstream breakers; choose Icn/Icu to hold tripping under real faults.

Environment Pick IP30–IP41 for corridors; raise to IP54–IP65 in plant and wash-down zones; target IK08 where carts or pallets run close.

Circuit strategy Decide all-RCBO vs split-load; include Type A or F RCDs for drives and EV loads; size SPDs to system earthing and exposure.

Space and heat Check module count with 20–30% spare ways; leave cableways for neat routing; allow ventilation or higher depth near RCBO rows.

Cabling and entries Match gland plates to actual cable OD; reserve bottom and top entry options to avoid tight bending radii.

Testing and handover Specify test points, engraved labels, circuit schedules behind doors, and QR links to as-built drawings for fast audits.

Advantages of working with Bankoflamps

You receive project-specific pricing against your circuit schedule, a named account manager, and live EU stock visibility before commitment. Quotes land quickly so night shifts and weekend cutovers stay on plan. Orders by EAN or MPN post cleanly into your ERP; downloadable price lists remain current through revisions. Your portal shows lead times and order status, plus purchase-history analytics to standardise device types and enclosure sizes across sites. Trusted clients can use post-payment terms up to 30 days. We coordinate consolidated shipments for multi-location drops and set price-validity windows so phased installs remain predictable.