Rutenbeck Fibre optic cables

rutenbeck fibre optic cables for enterprise and campus networks

Fit‑outs that mix IT and building services need fiber that installs cleanly and measures on spec the first time. Rutenbeck lines cover pre‑terminated trunks for fast rollouts, tight‑buffer indoor runs for patching and risers, and ruggedized assemblies for plant corridors where vibration and dust are part of the day.

rutenbeck multimode fiber product range and formats

OM3/OM4 50/125 µm for 1/10G access and short backbone hops; OM5 wideband options where SWDM is planned. Jackets in LSZH for public routes; plenum/LSHF variants on request. Constructions include tight‑buffer (900 µm) for indoor termination, distribution for risers (2–24 fibers), and breakout with 2.0 mm sub‑units for direct connectorization.

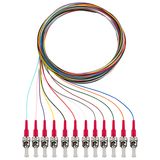

Connector systems: LC/UPC for density, SC/UPC where legacy exists, and LC/APC for PON or high‑RL links. Factory‑polished ferrules give predictable loss and polish geometry; dust caps and strain‑relief boots survive repeated service.

MPO/MTP trunks: 8/12/24‑fiber backbones with pinned/unpinned variants, polarity Type A/B/C per site standard, and cassette modules to fan out to LC at the rack.

rutenbeck singlemode cables technical specifications and standards

- Fiber types: G.652.D low‑water‑peak for general links; G.657.A1/A2 bend‑insensitive for cabinet routing and tight spaces.

- Optical windows: 1310/1550 nm for classic Ethernet; CWDM/DWDM where channelization is required.

- Attenuation targets (typ.): 0.35 dB/km @ 1310 nm, 0.22 dB/km @ 1550 nm singlemode; multimode ≤3.0 dB/km @ 850 nm (OM3) and ≤3.5 dB/km (OM4).

- Connector losses (factory‑terminated, typ.): ≤0.2–0.3 dB per mated LC/SC; return‑loss UPC ≥ 50 dB, APC ≥ 60 dB.

- Mechanical: minimum bend radius fixed ≥10× OD, dynamic ≥20× OD (tighter for G.657.A2); pull strength and crush per cable datasheet.

- Fire & CPR: jackets rated to EN 50575 with available Eca/Dca/Cca/B2ca classes; LSZH smoke and acidity per EN 61034/EN 60754.

- System standards: structured cabling to ISO/IEC 11801‑1 / EN 50173; cable families per IEC 60793/60794; connectors per IEC 61754; performance tests to IEC 61300.

Document OTDR and Tier‑1 results in the handover pack; keep reference cords matched to connector type and polish.

rutenbeck fiber patch cords applications and compatibility

- Racks and cabinets: LC‑LC patching to 10G/25G access; use short bend‑insensitive jumpers and radius guides to protect ferrules. Color coding follows site policy for SM/MM separation

- MDF/IDF backbones: MPO/MTP trunks with cassette fan‑outs to LC, polarity verified on delivery. Keep slack on lacing bars; avoid over‑tight cable ties.

- Industrial edges: armored or ruggedized jumpers where trays are shared with control wiring; maintain separation from VFD mains.

All assemblies seat into EU 19″ practice with Rutenbeck/partner panels, cassettes, and faceplates; tool sets and labels remain common across sites.

rutenbeck optical backbone cables integration with other brand products

Route pre‑terminated trunks through brush/EMC plates into Rittal‑class enclosures, then intercept mechanical load on clamp rails before the patch field. Use radius‑managed organizers and closed cassettes to keep dust off ferrules. Where copper and fiber coexist, reserve side channels for fiber and maintain 360° bonding on screened copper at entry plates to stabilize EMC.

For outdoor links, specify duct‑grade loose‑tube with water‑swell elements and UV‑stable jackets; land indoors on short indoor pigtails via splice trays

rutenbeck fiber network solutions selection criteria for B2B clients

- Bandwidth and reach — OM3/OM4 for 10G access and short runs; OM5 when SWDM is planned; OS2 for campus/corridor backbones and WDM.

- Connector strategy — LC density vs SC legacy; APC where RL is critical; MPO/MTP for high‑count trunks with cassette fan‑out.

- Cable build & CPR — tight‑buffer for indoor termination; distribution for risers; breakout for direct termination; specify Eca/Dca/Cca/B2ca by building zone.

- Bend and routing — prefer G.657.A2 in cabinets and hinges; keep bend radius within spec and use radius guides.

- Testing & documentation — Tier‑1 channel tests plus OTDR where required; record polarity and link budgets.

Stock planners usually hold one LC/UPC multimode line, one LC/UPC OS2 line, and standardized MPO trunks with matched cassettes—training and spares stay simple.

advantages of working with Bankoflamps

We tune commercial terms to your BOM: individual B2B pricing and formal offers, a dedicated account manager, and live EU‑wide stock visibility. Quotes typically arrive in about an hour. Orders are placed by EAN/MPN for clean traceability, and our price lists are downloadable and current. You get lead‑time and order‑status tracking, purchase‑history analytics for SKU consolidation, and post‑payment up to 30 days for trusted clients. We also plan consolidated shipments to reduce freight costs, hold prices with validity windows, and support teams in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.